A Laser Vibration Measurement System

A vibration measurement and laser technology, which is applied to measurement devices, ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of low measurement result accuracy and inability to automatically focus, improve safety, enhance measurement efficiency and measurement accuracy, The effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

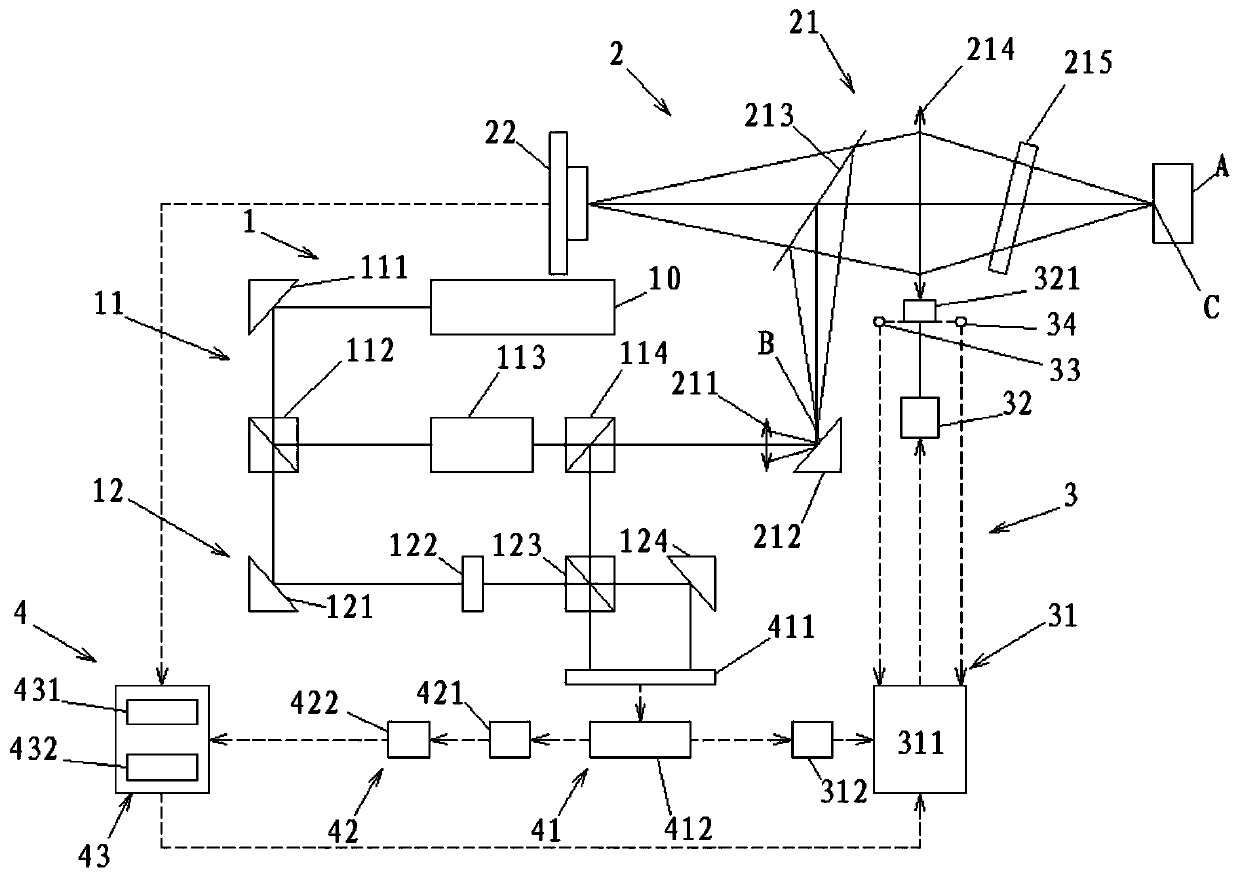

[0092] Such as figure 1 As shown, according to an embodiment of the present invention, the focusing subunit 21 includes: a rear lens 211 , a first mirror 212 , a first beam splitter 213 , a front lens group 214 , and a first wave plate 215 . In this embodiment, the rear lens 211 , the first reflection mirror 212 , the first beam splitter 213 , the front lens group 214 , and the first wave plate 215 are sequentially arranged to form the first optical path. In this embodiment, the second optical path is connected with the first optical path through the third beam splitter 114 and the rear lens 211 . The measurement light transmitted by the third beam splitter 114 is delivered to the rear lens 211, the measurement light is focused by the rear lens 211, and the focused measurement light is delivered to the first reflector 212, and reflected by the first reflector 212, The measurement light is focused to the first focal point B, and after entering the first focal point B, the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com