Bi and Nd composite reinforced high-strength cast magnesium alloy and preparation method thereof

A casting magnesium alloy, high-strength technology, applied in the field of high-strength casting magnesium alloy, Mn, magnesium alloy containing Al, Zn, Bi and Nd, can solve the problem of low strength, achieve tensile strength improvement, excellent comprehensive mechanical properties, Effect of Yield Strength Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

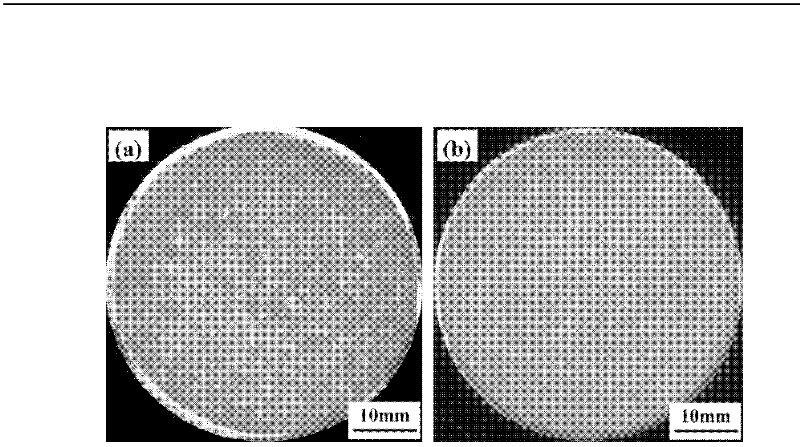

Image

Examples

Embodiment 1

[0019] In this embodiment, the alloy composition (weight percentage) is: 8.0% Al, 0.5% Zn, 0.2% Mn, 0.6% Bi, 0.8% Nd, impurity elements Fe0.003%, Cu0.008%, Ni0.001%, The remainder is Mg.

[0020] (1) Preheat pure Mg and pure Al at 200°C, preheat pure Bi, Mg-Nd and Al-Mn master alloys at 100°C, and dry them; at the same time, the conventional magnesium alloy refining agent RJ- 2 and the mold is preheated at 250°C.

[0021] (2) Heat the crucible to 730°C in a resistance furnace, and then put pure Mg in CO 2 with SF 6 Mixed gas (SF 6 The volume fraction is 0.5%) and melted in a crucible under protection. After melting, when the melt temperature is 730°C, add preheated pure Al, pure Bi, pure Zn, Al-Mn master alloy and Mg to the melt -Nd intermediate alloy, then stir the alloying elements until completely dissolved into the melt, heat the melt to 730-750°C and add conventional magnesium alloy refining agent RJ-2 accounting for 1wt% of the melt for refining, keep it at 730-750°C...

Embodiment 2

[0030] The difference from Example 1 is:

[0031] In this example, the components and weight percentages of the high-strength cast magnesium alloy strengthened by Bi and Nd are: 9.0% Al, 0.6% Zn, 0.2% Mn, 1.0% Bi, 0.5% Nd, impurity element Fe0.002% , Cu0.010%, Ni0.001%, and the rest is Mg.

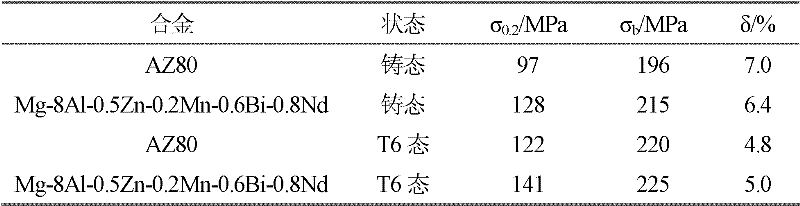

[0032] The yield strength of the alloy in the casting state of the invention is 105MPa, the tensile strength is 203MPa, and the elongation is 7.2%. In the T6 state, the yield strength is 135MPa, the tensile strength is 230MPa, and the elongation is 4.8%.

Embodiment 3

[0034] The difference from Example 1 is:

[0035]In this example, the components and weight percentages of the high-strength cast magnesium alloy strengthened by Bi and Nd are: 7.0% Al, 0.3% Zn, 0.3% Mn, 0.2% Bi, 1.2% Nd, impurity element Fe0.001% , Cu0.009%, Ni0.001%, and the rest is Mg.

[0036] The yield strength of the alloy in the casting state of the invention is 104MPa, the tensile strength is 224MPa, and the elongation is 8.4%. In the T6 state, the yield strength is 140MPa, the tensile strength is 232MPa, and the elongation is 5.0%.

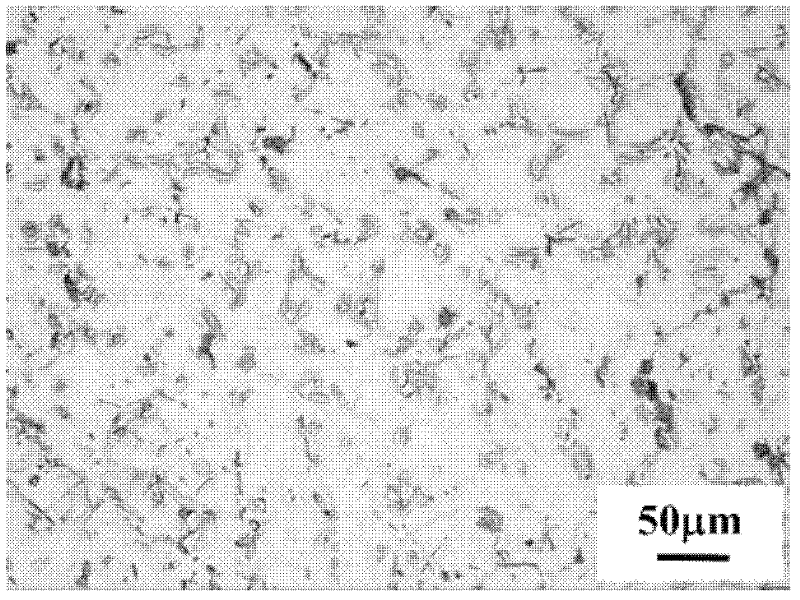

[0037] Embodiment 2,3 result shows, the present invention generates Mg simultaneously by adding Bi and Nd 3 Bi 2 、Al 2 Nd and Al 11 Nd 3 Magnesium alloys are strengthened by phase compounding, and Mg-Al-Zn-Mn-Bi-Nd alloys with excellent as-cast and heat-treated properties are obtained by means of precipitation strengthening and fine-grain strengthening. The yield strength and tensile strength of the alloy in the casting state and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com