High-temperature-resistant and corrosion-resistant washable industrial dust removal device

A dust removal device, corrosion-resistant technology, applied in transportation and packaging, dispersed particle filtration, gas treatment, etc., can solve the problems of incomplete filtration of smoke and dust bacteria, inability to clean and reuse, and inability to achieve high purification and removal. The effect of excellent dust removal and filtration performance, excellent mechanical and mechanical properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

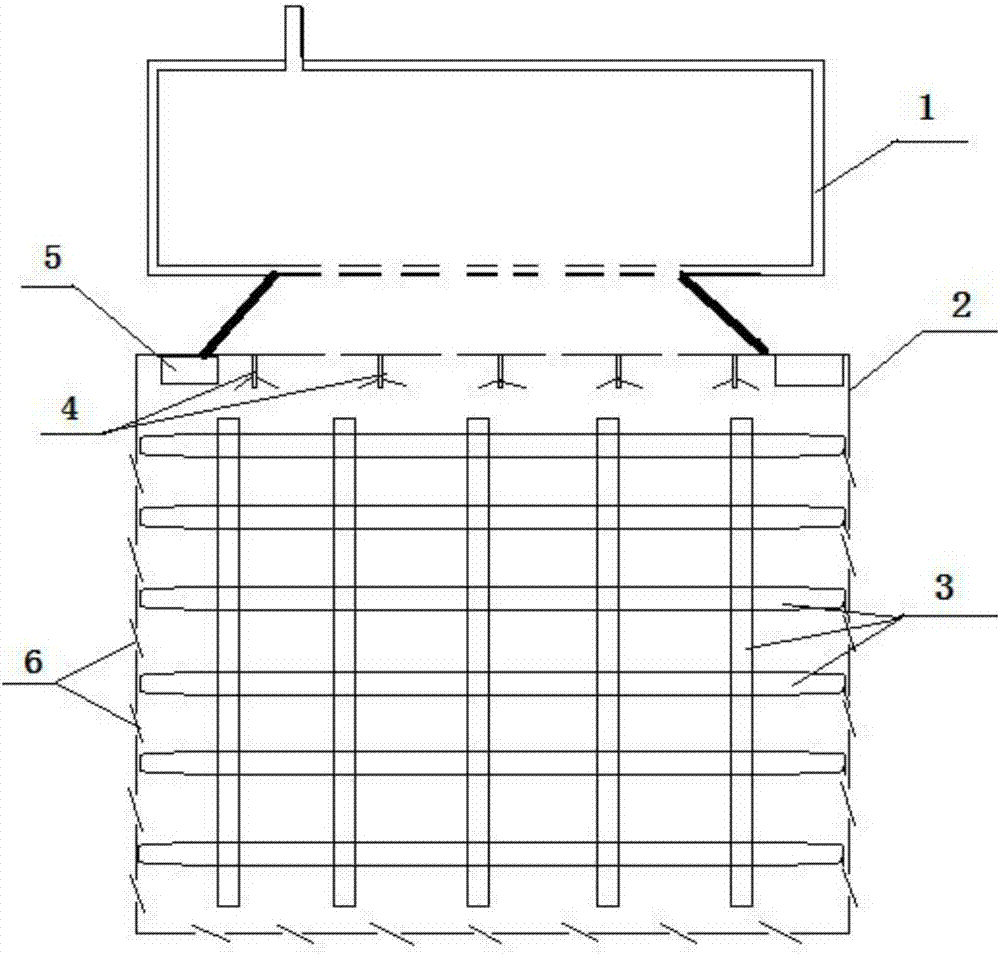

[0033] Such as figure 1 As shown, a high-temperature, corrosion-resistant and washable industrial dust removal device includes a dust removal box 1, a suction device 2 connected to the top of the dust removal box 1, and a filter element 3 installed inside the dust removal box 1;

[0034] The filter element 3 is installed in the dust removal box 1 in a crisscross pattern;

[0035] The filter element 3 is a woven fabric obtained by blending polyphenylene sulfide yarn, basalt fiber yarn, carbon fiber yarn and aramid fiber yarn. The fluoromesi needle felt on the upper and lower surfaces of the woven fabric is needle-punched. The glass fiber water needle felt on the surface of the needle felt, the microporous film coated on the surface of the glass fiber water needle felt; the silica aerogel bonded to the surface of the microporous film, is bonded to the silica Made of HEPA high-efficiency filter on the surface of the aerogel;

[0036] A movable grille 6 is provided around and at the bo...

Embodiment 2

[0052] Such as figure 1 As shown, a high-temperature, corrosion-resistant and washable industrial dust removal device includes a dust removal box 1, a suction device 2 connected to the top of the dust removal box 1, and a filter element 3 installed inside the dust removal box 1;

[0053] The filter element 3 is installed in a cross in the dust removal box 1;

[0054] The filter element 3 is a woven fabric obtained by blending nano-polyphenylene sulfide yarn, nano-basalt fiber yarn, nano-carbon fiber yarn and nano-aramid fiber yarn. The glass fiber water needle felt pierced on the surface of the flumesi needle felt, the microporous film coated on the surface of the glass fiber water needle felt; the silica aerogel adhered to the surface of the microporous film, bonded Made of HEPA high efficiency filter on the surface of silica aerogel;

[0055] A movable grille 6 is provided around and at the bottom of the dust removal box 1, and the shafts at both ends of the movable grille 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com