Graphene modified radiating consuming material for printing and application thereof

A graphene modification, graphene technology, applied in additive processing, instruments, electrical digital data processing and other directions, can solve problems such as poor heat dissipation performance of notebook computer shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

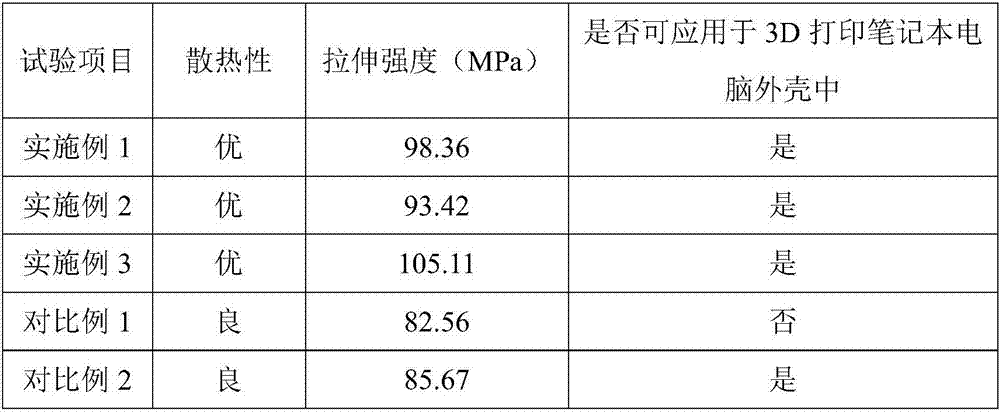

Examples

preparation example Construction

[0059] The preparation method of the graphene-modified heat dissipation material for printing comprises the following steps:

[0060] S1: crush the PET resin and glycol ether acetate and pass through a 200-300 mesh sieve to obtain mixed resin powder;

[0061] S2: adding a surfactant to the mixed resin powder prepared in step S1, and activating it for 1-1.3 hours at a temperature of 68-72° C. and a rotational speed of 150-180 r / min to prepare an activated mixed resin powder;

[0062] S3: Pulverize the graphene and pass it through a 200-300 mesh sieve to obtain a powder. The obtained powder is under a magnetic field strength of 7000-8200GS, an ultrasonic power of 520-650W, a temperature of 52-56°C, and a rotation speed of 200-300r / min. , stirring for 40-50min to obtain graphene energy powder;

[0063] S4: Under the protection of nitrogen, add the graphene energy powder prepared in step S3, polylactic acid, sodium tripolyphosphate, chloropropyl styrene, maleic anhydride grafted ...

Embodiment 1

[0072] A graphene-modified heat-dissipating consumable for printing, comprising the following raw materials in parts by weight: 3 parts of graphene, 106 parts of PET resin, 30 parts of glycol ether acetate, 65 parts of polylactic acid, and 52 parts of sodium tripolyphosphate Parts, 15 parts of chloropropyl styrene, 12 parts of maleic anhydride grafted polypropylene, 10 parts of sodium hydroxymethyl cellulose, 5 parts of Kevlar fiber, 4 parts of polybutylene terephthalate fiber, surface 1.3 parts of active agent, 0.6 parts of regulator, 0.4 parts of generating agent, 0.6 parts of crosslinking agent, 1 part of compatibilizer, 0.7 parts of bridging agent, 0.4 parts of catalyst, 0.7 parts of plasticizer, 0.4 parts of dispersing agent, thickening 0.6 parts of curing agent, 1.6 parts of curing agent, 0.4 parts of antioxidant, 0.3 parts of stabilizer, 1.5 parts of anti-aging agent, 2 parts of flame retardant;

[0073] The surfactant is polyoxyethylene-polyoxypropylene copolymer;

[...

Embodiment 2

[0100] A graphene-modified heat-dissipating consumable for printing, which includes the following raw materials in parts by weight: 1.7 parts of graphene, 75 parts of PET resin, 22 parts of glycol ether acetate, 50 parts of polylactic acid, and 32 parts of sodium tripolyphosphate 11 parts of chloropropyl styrene, 10 parts of maleic anhydride grafted polypropylene, 8 parts of sodium hydroxymethyl cellulose, 4 parts of Kevlar fiber, 3 parts of polybutylene terephthalate fiber, surface 1 part of activator, 0.4 part of regulator, 0.3 part of generating agent, 0.4 part of crosslinking agent, 0.7 part of compatibilizer, 0.5 part of bridging agent, 0.3 part of catalyst, 0.5 part of plasticizer, 0.3 part of dispersant, thickener 0.4 parts of curing agent, 1 part of curing agent, 0.3 parts of antioxidant, 0.2 parts of stabilizer, 1.2 parts of anti-aging agent, 1.8 parts of flame retardant;

[0101] The surfactant is polyoxyethylene-polyoxypropylene copolymer;

[0102] The regulator is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com