Bus plugging box with very high stability

A technology of stable performance and plug-in box, which is applied in the direction of fully enclosed busbar installations, etc., and can solve the problem of whether the contact between the lower end of the busbar plug-in box and the copper bar is not tight, not firm, unreliable, and the contact is not tight or firm, increasing safety hazards, etc. problem, to achieve the effect of improving the fixing effect, avoiding short circuit, and increasing the bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

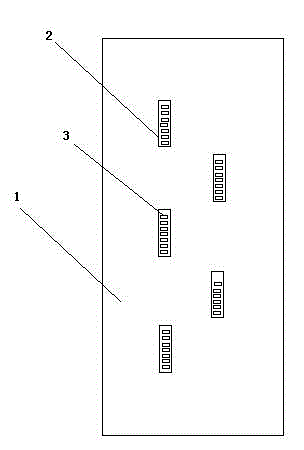

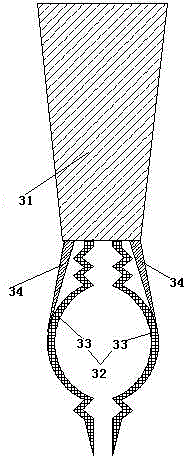

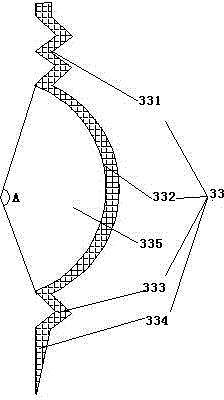

[0018] As shown in the figure, a busbar plug-in box with extremely high stability includes a box body 1, wherein a plurality of plug-in ports 2 are provided on the back of the box body 1, and a plurality of plug-in ports 2 are provided on the plug-in port 2. Pin 3, the pin 3 includes a central copper column 31, the central copper column 31 is fixed inside the socket 2, the lower end of the central copper column 31 is provided with a fixed fitting mechanism 32, and the fixed fitting mechanism 32 includes two sticking Laminating plate 33, the laminating plate 33 is axisymmetrically distributed, and the laminating plate 33 is an integrated structure, including a first fixing portion 331, an arc portion 332, a second fixing portion 333, and a tip fitting portion 334; The first fixing part 331 is on the top of the bonding plate 33, and its cross-section is a tooth-shaped structure, and the tooth-shaped structure is "W"-shaped; 332 is bent outward, forming an arc-shaped cavity 335 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com