Anti-corrosion, anti-stretching, and direct burial water-blocking medium-voltage cable

An anti-stretch and anti-corrosion technology, which is applied in anti-corrosion, directly buried water-blocking high-voltage cables, and anti-stretch fields, can solve the problems of low tensile strength of cables, easy corrosion and corrosion resistance of cables, and inconvenient fixing, etc., to achieve Improve mechanical performance and moisture-proof effect, ensure safe operation, and prevent the infiltration of moisture and moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

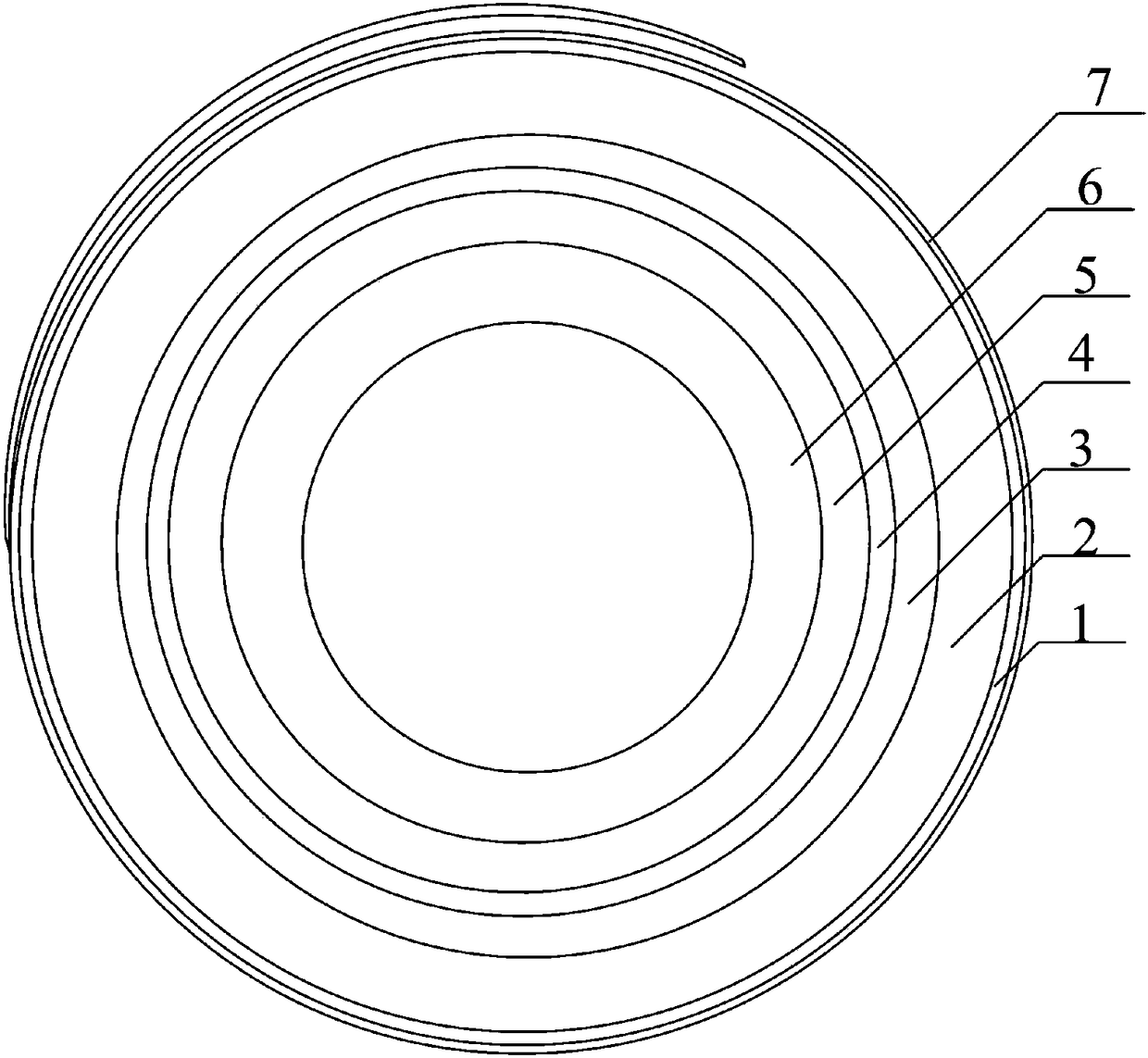

[0029] as attached figure 1 to attach Figure 4 shown

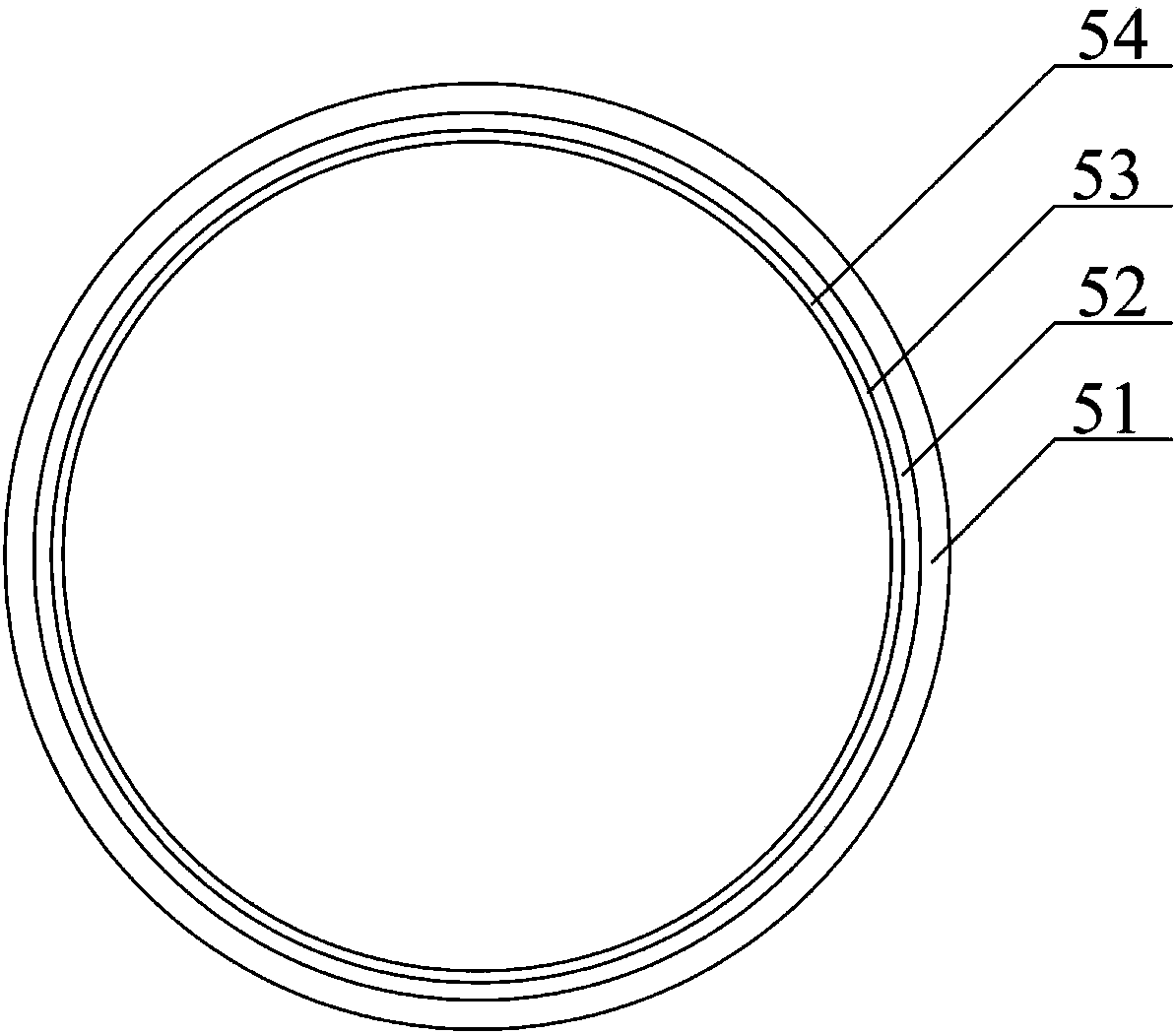

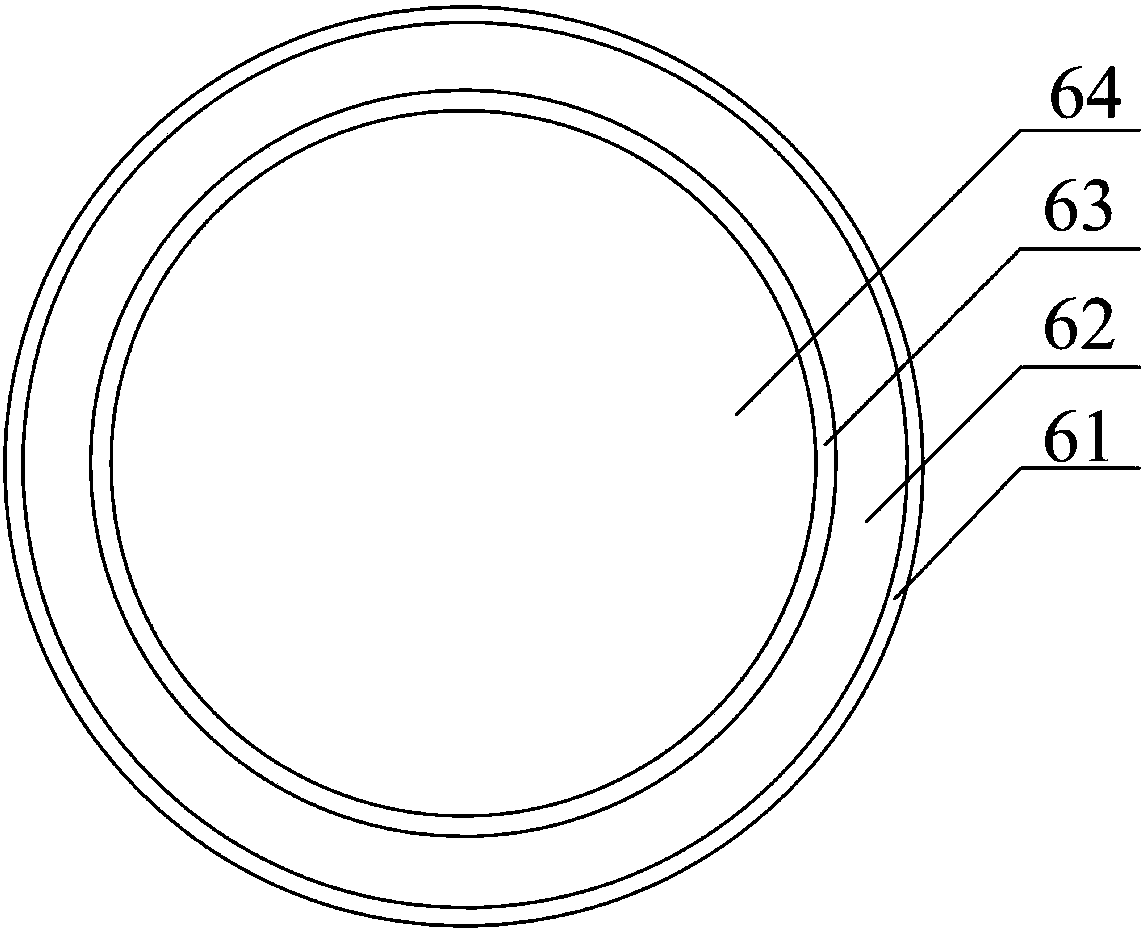

[0030] The invention provides a corrosion-resistant, stretch-resistant, direct-buried water-blocking high-voltage cable, which includes a semiconductive graphite coating layer 1, an HDPE outer sheath layer 2, an aluminum alloy wire armor layer 3, an MDPE isolation sleeve 4, and a multi-layer shield The protective structure 5, the conductor insulation water blocking layer structure 6 and the cable connection fixing belt structure 7, the semiconductive graphite coating layer 1 is coated on the outside of the HDPE outer sheath 2; the HDPE outer sheath 2 is extruded On the outside of the aluminum alloy wire armor layer 3; the aluminum alloy wire armor layer 3 bundles are wound on the outside of the multilayer shielding protection structure 5; the multilayer shielding protection structure 5 is extruded or wrapped around the conductor insulation The outer side of the water-blocking layer structure 6; the cable connection fixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com