Paper-based/silica sol/polyvinyl alcohol (PVA) color-changing composite film for detecting water-injected meat, preparation method and application thereof

A technology of polyvinyl alcohol and silica sol, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, papermaking, paper, etc., can solve the problems of inability to realize quantitative detection of water-injected meat, poor dissolution resistance and mechanical properties, and individual sensory Differential effects and other issues, to achieve the effect of excellent tensile strength, excellent mechanical properties, and good resistance to dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A paper base / silica sol / PVA color-changing composite film for detecting water-injected meat and its production method:

[0034] Step 1: Pretreatment of ion exchange resin: Soak 732 strong acid styrene cation exchange resin with 10% sodium chloride solution with solute mass fraction for 24 hours, then rinse with clear water until the washing water is colorless, and use a mass fraction of 2% Soak in sodium hydroxide solution for 2 hours, drain the lye, rinse with distilled water until the pH of the lotion is 8.5, then soak in 5% hydrochloric acid solution for 4 hours, drain the acid, and then rinse with distilled water until the pH of the lotion is 8.5. The pH is 5, and finally the resin is dried to constant weight;

[0035] Step 2: Configuration of sodium metasilicate solution with a mass fraction of 3.5%: Weigh 7 g of sodium metasilicate reagent and dissolve it in 193 ml of distilled water, stir with a glass rod to make it evenly mixed;

[0036] Step 3: Preparation of ...

Embodiment 2

[0043] Step 1: Pretreatment of ion exchange resin: Soak 732 strong acid styrene cation exchange resin with 10% sodium chloride solution with solute mass fraction for 24 hours, then rinse with clear water until the washing water is colorless, and use 4% mass fraction Soak in sodium hydroxide solution for 2 hours, drain the lye, rinse with distilled water until the pH of the lotion is 9.5, then soak in 5% hydrochloric acid solution for 4 hours, drain the acid, and then rinse with distilled water until the pH of the lotion is 9.5. The pH is 6, and finally the resin is dried to constant weight;

[0044] Step 2: The configuration of sodium metasilicate solution with a mass fraction of 3.5%: weigh 7g of sodium metasilicate reagent and dissolve it in 193ml of distilled water, stir with a glass rod to make it evenly mixed;

[0045] Step 3: Preparation of silica sol: Accurately weigh 1.000g of the ion exchange resin obtained in step 1 into a 250ml Erlenmeyer flask, then add 100ml of th...

Embodiment 3

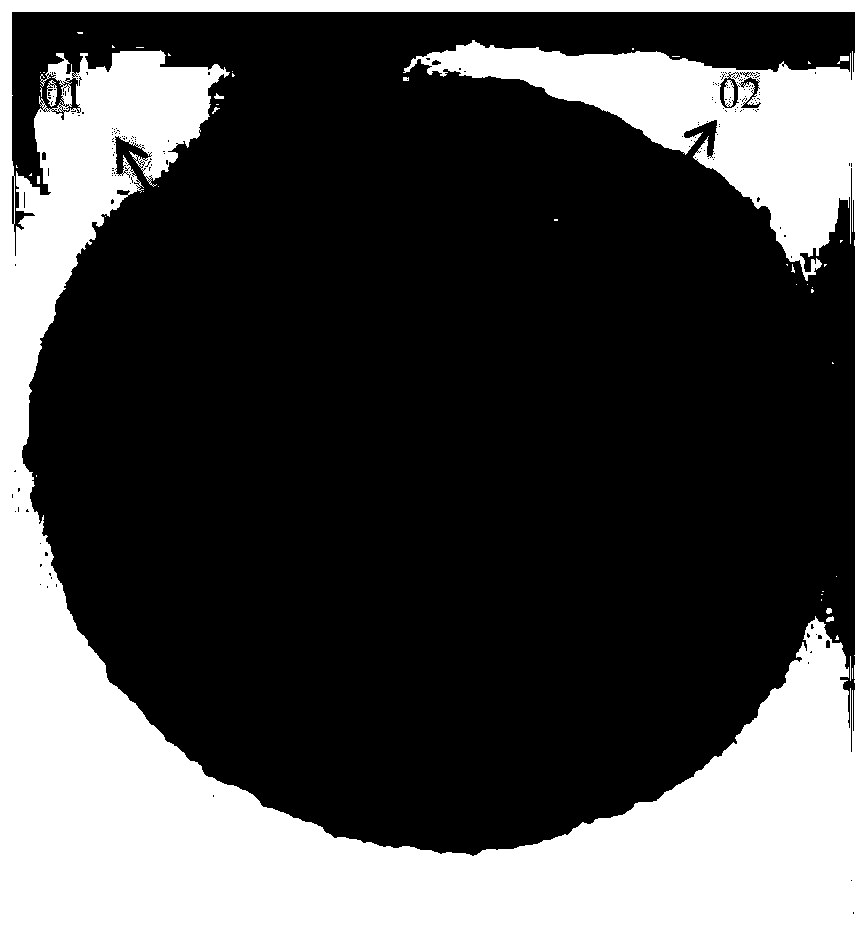

[0052] Step 1: Cut the pork tenderloin sample to be tested into meat pieces whose length, width and height are respectively 3×2×1cm (mass 7-10g) along the direction perpendicular to the muscle fibers;

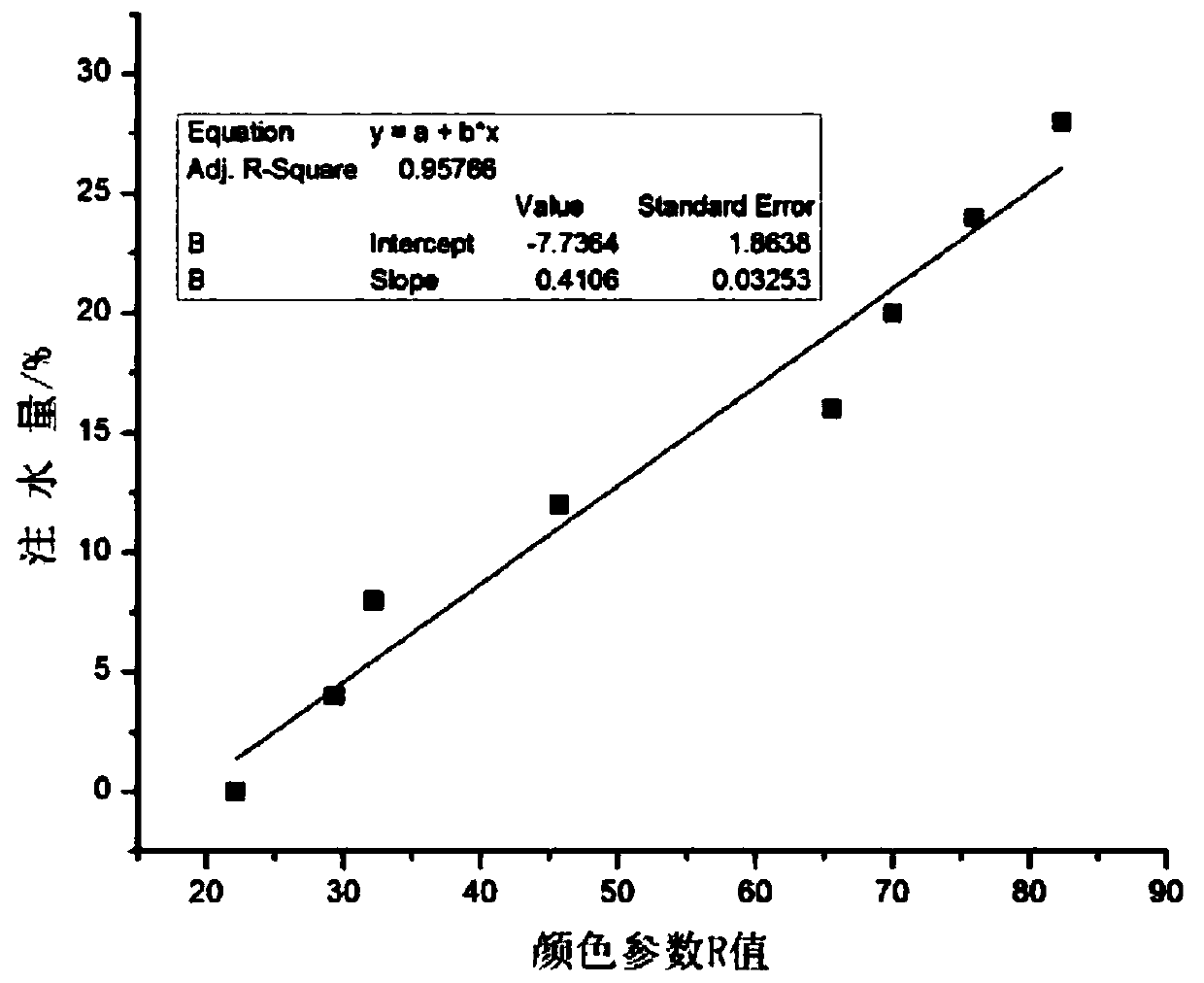

[0053] Step 2: Use a 0.5ml syringe to inject distilled water into the center of the four sides of the meat sample, take eight kinds of meat samples and inject the meat sample quality 0, 4%, 8%, 12%, 16%, 20%, 24%, 28% distilled water (each sample is carried out 3 parallel tests);

[0054] Step 3: Use tweezers to attach the color-changing composite film to the surface of the meat sample, and quickly place a weight composed of 12 glass slides on the color-changing composite film to make the color-changing composite film fully contact with the meat sample;

[0055] Step 4: Remove the weight immediately after 3 minutes, use tweezers to peel off the color-changing composite film from the meat sample, and use the TCS34725 color sensor to collect 6 points on the color-changing area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com