Wingceltis skin and bagasse fiber composite paper filter material and preparation method and application thereof

A bagasse fiber, paper technology, applied in the application, smoke oil filter, tobacco and other directions, can solve the problem of poor taste and other problems, achieve the effect of reducing irritation and dry feeling, reducing smoke tar and clear aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

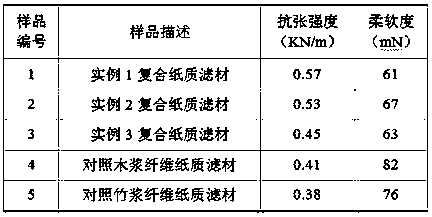

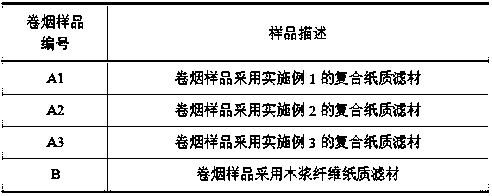

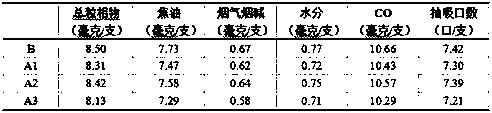

Examples

Embodiment 1

[0024] The preparation method of the sandalwood bark and bagasse fiber composite paper filter material of the present embodiment is prepared through the following steps:

[0025] (1) Preparation of paper base: Take commercially available sandalwood pulp board and bagasse paddle board according to the dry weight ratio of 6:4, and after hydropulping and dispersing, use PFI refiner to refine pulp. The concentration is 5% by mass, and the degree of beating is 35 ºSR. After adding conventional additives to the slurry, it is made on a paper sheet forming machine, and the paper sheet is dried for later use. The weight of the control paper is 37±1 g / m2, and the thickness is 0.12±0.02 mm;

[0026] (2) Preparation of the coating liquid: take ebony and licorice according to the mass ratio of 7:3, mix and crush them, and then carry out heat reflux extraction with water to obtain the extract liquid. The solid-liquid ratio (w / v) during extraction is 1:30, and the extraction temperature is ...

Embodiment 2

[0030] The preparation method of the sandalwood bark and bagasse fiber composite paper filter material of the present embodiment is prepared through the following steps:

[0031] (1) Preparation of paper base: Take commercially available sandalwood pulp board and bagasse paddle board according to the dry weight ratio of 9:1, and then use PFI refiner to refine the pulp after hydropulping and dispersing. The concentration is 8% by mass, and the degree of beating is 38 ºSR. After adding conventional additives to the slurry, it is made on a paper sheet forming machine, and the paper sheet is dried for later use. The weight of the control paper is 37±1g / m2, and the thickness is 0.12±0.02mm;

[0032] (2) Preparation of the coating liquid: Take black plum and licorice according to the mass ratio of 3:7, mix and crush them, and then carry out heat reflux extraction with water to obtain the extract liquid. The solid-liquid ratio (w / v) during extraction is 1:25, and the extraction tempe...

Embodiment 3

[0036] The preparation method of the sandalwood bark and bagasse fiber composite paper filter material of the present embodiment is prepared through the following steps:

[0037] (1) Preparation of paper base: Take commercially available sandalwood pulp board and bagasse paddle board according to the dry weight ratio of 8:2, and after hydropulping and dispersing, use PFI refiner to refine pulp. The concentration is 9% by mass, and the beating degree is 42 ºSR. After adding conventional additives to the slurry, it is made on a paper sheet forming machine, and the paper sheet is dried for later use. The weight of the control paper is 37±1 g / m2, and the thickness is 0.12±0.02 mm;

[0038] (2) Preparation of the coating liquid: Take black plum and licorice according to the mass ratio of 4:6, mix and crush them, and then heat reflux extraction with water to obtain the extract liquid. The solid-liquid ratio (w / v) during extraction is 1:35, and the extraction temperature is 60°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com