Art design packaging film material

A packaging film and art technology, applied in the field of art design packaging film materials, can solve problems such as poor performance, achieve superior flame retardancy, and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

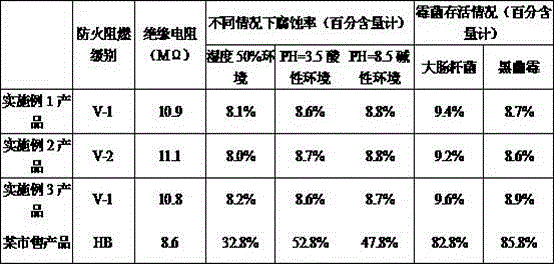

Embodiment 1

[0016] The art design packaging film material in the present embodiment is made up of the following components in mass parts: 18 parts of chlorinated polyethylene, 16 parts of chlorosulfonated polyethylene resin, 16 parts of epichlorohydrin rubber, diethyl ethyl phosphonate 14 parts, 16 parts of trimethyl phosphate, 16 parts of trichloroethyl phosphate, 14 parts of potassium titanate whisker reinforcement, 16 parts of garlic oil, 16 parts of tea polyphenol, dodecyl dimethyl benzyl chloride 14 parts of ammonium, 14 parts of zinc pyrithione, 14 parts of 10,10'-oxobisphenoxarsenic, 16 parts of chimney ash, 14 parts of calcium oxide powder, 12 parts of cobalt oxide powder, 16 parts of manganese oxide powder, tin oxide 14 parts of powder, 12 parts of luminous powder, 14 parts of sodium stearate, 12 parts of ethylenediamine tetramethylene phosphonic acid, 12 parts of isobutyltriethoxysilane, 14 parts of dimethylformamide, 14 parts of cottonseed oil , 14 parts of aniline, 14 parts of...

Embodiment 2

[0022] The art design packaging film material in the present embodiment is made up of the following components in parts by mass: 20 parts of chlorinated polyethylene, 18 parts of chlorosulfonated polyethylene resin, 18 parts of epichlorohydrin rubber, diethyl ethyl phosphonate 16 parts, 18 parts of trimethyl phosphate, 18 parts of trichloroethyl phosphate, 16 parts of potassium titanate whisker reinforcement, 18 parts of garlic oil, 18 parts of tea polyphenols, dodecyl dimethyl benzyl chloride 16 parts of ammonium, 16 parts of zinc pyrithione, 16 parts of 10,10'-oxobisphenoxarsenic, 18 parts of chimney ash, 16 parts of calcium oxide powder, 14 parts of cobalt oxide powder, 18 parts of manganese oxide powder, tin oxide 16 parts of powder, 14 parts of luminous powder, 16 parts of sodium stearate, 14 parts of ethylenediamine tetramethylene phosphonic acid, 14 parts of isobutyltriethoxysilane, 16 parts of dimethylformamide, 16 parts of cottonseed oil , 16 parts of aniline, 16 part...

Embodiment 3

[0028] The artistic design packaging film material in the present embodiment is made up of the following components in parts by mass: 22 parts of chlorinated polyethylene, 20 parts of chlorosulfonated polyethylene resin, 20 parts of epichlorohydrin rubber, diethyl ethyl phosphonate 18 parts, 20 parts of trimethyl phosphate, 20 parts of trichloroethyl phosphate, 18 parts of potassium titanate whisker reinforcement, 20 parts of garlic oil, 20 parts of tea polyphenols, dodecyl dimethyl benzyl chloride 18 parts of ammonium, 18 parts of zinc pyrithione, 18 parts of 10,10'-oxobisphenoxarsenic, 20 parts of chimney ash, 18 parts of calcium oxide powder, 16 parts of cobalt oxide powder, 20 parts of manganese oxide powder, tin oxide 18 parts of powder, 16 parts of luminous powder, 18 parts of sodium stearate, 16 parts of ethylenediamine tetramethylene phosphonic acid, 16 parts of isobutyltriethoxysilane, 18 parts of dimethylformamide, 18 parts of cottonseed oil , 18 parts of aniline, 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com