Preparation method of novel flame-retardant antibacterial acrylic fabric

A technology of acrylic fibers and fabrics, applied in the field of textile fabrics, can solve the problems of poor antibacterial and flame retardant properties, and achieve the effects of improving flame retardant strength, expanding application space, and good inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

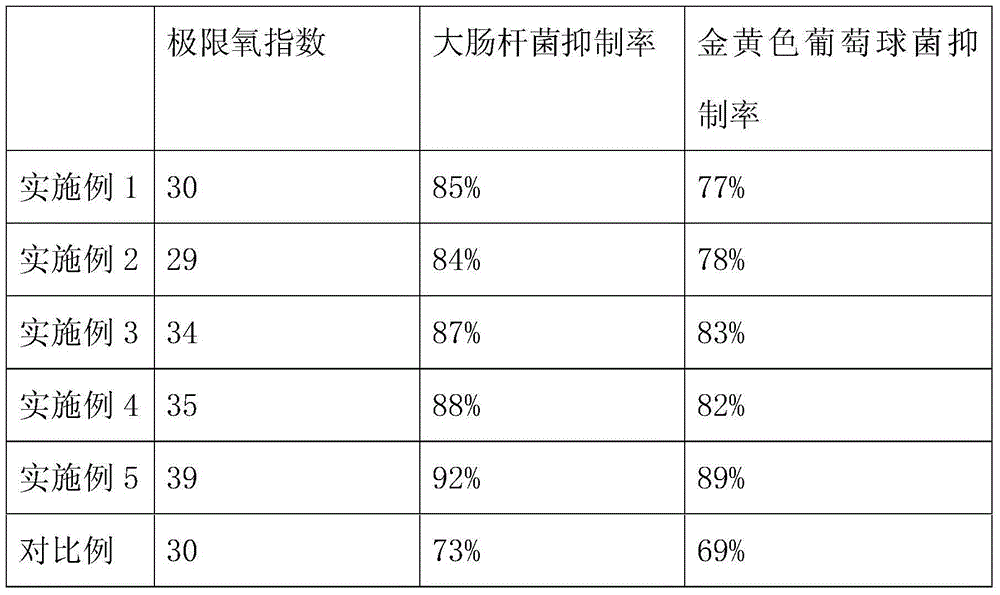

Examples

Embodiment 1

[0015] (1) Take triaryl phosphate by weight as 5Kg, trichloroethyl phosphate 10Kg, Tween-65 as 16Kg, glycerin as 4Kg, water as 110Kg, heat and stir the above five ingredients, and stir until uniform; ( 2) Completely immerse the acrylic fabric in the flame-retardant finishing solution prepared in step (1), place it at room temperature for 1.5h, dip it twice and roll it twice, the excess rate is 60%, and dry it at 95°C; (3) Take it by weight Ammonium dihydrogen phosphate is 6Kg, chitosan is 7Kg, Eupatorium 20wt% ethanol water extract is 5Kg, dissolves with 90Kg water, stirs after dissolving; (4) after stirring, the acrylic fabric that step (2) arranges Completely immerse in the antibacterial finishing solution of step (3), place at room temperature for 2 hours, dip twice and roll twice, the excess rate is 80%, and dry at 95° C. After drying, it becomes a flame-retardant and antibacterial acrylic fabric.

Embodiment 2

[0017] (1) Take triaryl phosphate by weight as 12Kg, trichloroethyl phosphate 6Kg, Tween-65 as 10Kg, glycerol as 10Kg, water as 80Kg, heat and stir the above five components, and stir until uniform; ( 2) Completely immerse the acrylic fabric in the flame-retardant finishing solution prepared in step (1), place it at room temperature for 1.5h, dip it twice and roll it twice, the excess rate is 60%, and dry it at 95°C; (3) Take it by weight Ammonium dihydrogen phosphate is 3Kg, chitosan is 4Kg, Eupatorium 20wt% ethanol water extract is 3Kg, dissolves with 70Kg water, stirs after dissolving; Completely immerse in the antibacterial finishing solution of step (3), place at room temperature for 2 hours, dip twice and roll twice, the excess rate is 80%, and dry at 95° C. After drying, it becomes a flame-retardant and antibacterial acrylic fabric.

Embodiment 3

[0019] (1) Take triaryl phosphate by weight as 7Kg, trichloroethyl phosphate 9Kg, Tween-65 as 15Kg, glycerol as 6Kg, water as 90Kg, heat and stir the above five components until uniform; ( 2) Completely immerse the acrylic fabric in the flame-retardant finishing solution prepared in step (1), place it at room temperature for 1.5h, dip it twice and roll it twice, the excess rate is 60%, and dry it at 95°C; (3) Take it by weight Ammonium dihydrogen phosphate is 5Kg, chitosan is 5Kg, Eupatorium 20wt% ethanol water extract is 4Kg, dissolves with 75Kg water, stirs after dissolving; Completely immerse in the antibacterial finishing solution of step (3), place at room temperature for 2 hours, dip twice and roll twice, the excess rate is 80%, and dry at 95° C. After drying, it becomes a flame-retardant and antibacterial acrylic fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com