Art design packaging film material

A packaging film and art technology, applied in the field of artistic design packaging film materials, can solve problems such as poor performance, achieve superior flame retardancy and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

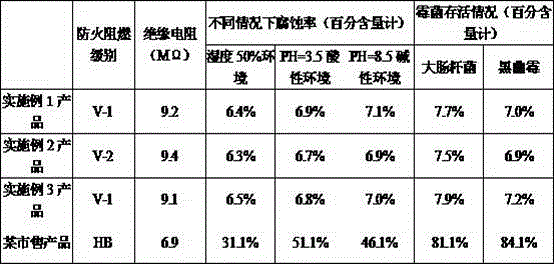

Embodiment 1

[0016] The artistic design packaging film material in this embodiment is composed of the following components in parts by mass: 28 parts of rosin pentaerythritol ester, 26 parts of ethylene-vinyl acetate copolymer, 26 parts of chloroether rubber, 24 parts of isobutyl propionate, 26 parts of epichlorohydrin, 26 parts of butyl acetate, 24 parts of glyceryl stearate, 26 parts of diethanolamine, 26 parts of dimethyl fumarate, 24 parts of cetyl bromide, 24 parts of imidazoline, fluorosilicone 24 parts of ammonium acid, 26 parts of antimony trioxide powder, 24 parts of chromium trioxide powder, 22 parts of quicklime powder, 26 parts of limestone powder, 24 parts of asbestos fiber, 22 parts of graphite fiber, 24 parts of disodium octaborate tetrahydrate, 24 parts of rosin 22 parts of powder, 22 parts of hexabromocyclododecane, 22 parts of triphenyl phosphate, 20 parts of sodium stannate, 16 parts of trichloroethyl phosphate, 14 parts of sodium methylene dinaphthalene sulfonate, tertiar...

Embodiment 2

[0022] The art design packaging film material in this embodiment is composed of the following parts by mass: 30 parts of rosin pentaerythritol ester, 28 parts of ethylene-vinyl acetate copolymer, 28 parts of chloroether rubber, 26 parts of isobutyl propionate, 28 parts of epichlorohydrin, 28 parts of butyl acetate, 26 parts of glyceryl stearate, 28 parts of diethanolamine, 28 parts of dimethyl fumarate, 26 parts of cetyl bromide, 26 parts of imidazoline, fluorosilicone 26 parts of ammonium acid, 28 parts of antimony trioxide powder, 26 parts of chromium trioxide powder, 24 parts of quicklime powder, 28 parts of limestone powder, 26 parts of asbestos fiber, 24 parts of graphite fiber, 26 parts of disodium octaborate tetrahydrate, rosin 24 parts of powder, 24 parts of hexabromocyclododecane, 24 parts of triphenyl phosphate, 22 parts of sodium stannate, 18 parts of trichloroethyl phosphate, 16 parts of sodium methylene dinaphthalene sulfonate, tertiary benzoic acid 16 parts of but...

Embodiment 3

[0028] The artistic design packaging film material in this embodiment is composed of the following components by mass: 32 parts of rosin pentaerythritol ester, 30 parts of ethylene-vinyl acetate copolymer, 30 parts of chloroether rubber, 28 parts of isobutyl propionate, 30 parts of epichlorohydrin, 30 parts of butyl acetate, 28 parts of glyceryl stearate, 30 parts of diethanolamine, 30 parts of dimethyl fumarate, 28 parts of cetyl bromide, 28 parts of imidazoline, fluorosilicone 28 parts of ammonium acid, 30 parts of antimony trioxide powder, 28 parts of chromium trioxide powder, 26 parts of quicklime powder, 30 parts of limestone powder, 28 parts of asbestos fiber, 26 parts of graphite fiber, 28 parts of disodium octaborate tetrahydrate, 28 parts of rosin 26 parts of powder, 26 parts of hexabromocyclododecane, 26 parts of triphenyl phosphate, 24 parts of sodium stannate, 20 parts of trichloroethyl phosphate, 18 parts of sodium methylene dinaphthalene sulfonate, tertiary benzoic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com