Ultraviolet light cross-linked high flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

A polyolefin cable material and ultraviolet light technology, applied in the field of low-smoke halogen-free flame retardant cable material, can solve the problems of uneven cross-linking degree, high cost of irradiation equipment, unfavorable cost control, etc., to promote mechanical properties, improve Mechanical properties, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

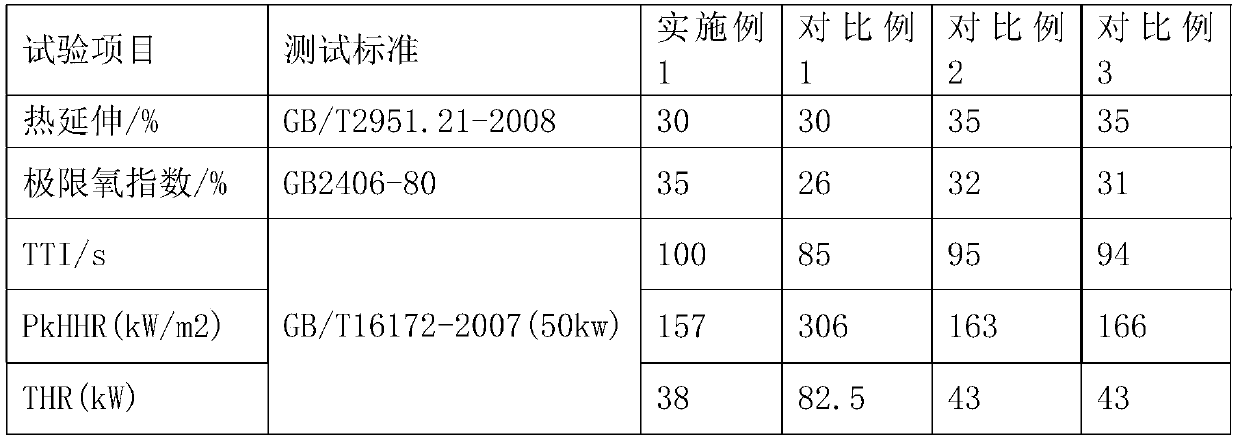

Examples

Embodiment 1

[0021] The raw material components of UV-crosslinked high flame-retardant low-smoke halogen-free polyolefin cable compound include: base material (ethylene-vinyl acetate (Yangzi BASF, 6110MC): ethylene-octene copolymer (Mitsui, DF840): low linearity Density polyethylene (Sinopec, 7042): maleic anhydride grafted polyethylene (JCP1000) with a mass ratio of 60:15:15:10) 100 parts, low-smoke halogen-free flame retardant (magnesium hydroxide (Aiteke, 10FG): aluminum hydroxide (Yabao, 104LEO) with a mass ratio of 2:1 mixture) 120 parts, multi-walled carbon nanotube synergistic flame retardant (Chengdu Organic Chemistry, TNIM1) 10 parts, Cationic initiator (dimethyliodonium salt (Shanghai Yuli Chemical): a mixture of triarylsulfonium salt (TCI) with a mass ratio of 1:1) 1 part, free radical initiator (2-hydroxy-2-methyl Base-1-phenyl-1-propanone (Huateng): benzophenone (Kunshan Wanjie) with a mass ratio of 1:1 mixture) 1 part, co-crosslinking agent triallyl isocyanurate (Hunan Minhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com