Method of preparing acetylated distarch adipate

A technology of powder adipate and acetylated secondary starch, which is applied in the field of modified starch and its preparation, can solve the problems of high temperature resistance, insufficient shear resistance, insufficient liquid transparency, insufficient brightness, insufficient high temperature resistance, etc. The effect of good liquid transparency, high degree of substitution and strong water retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

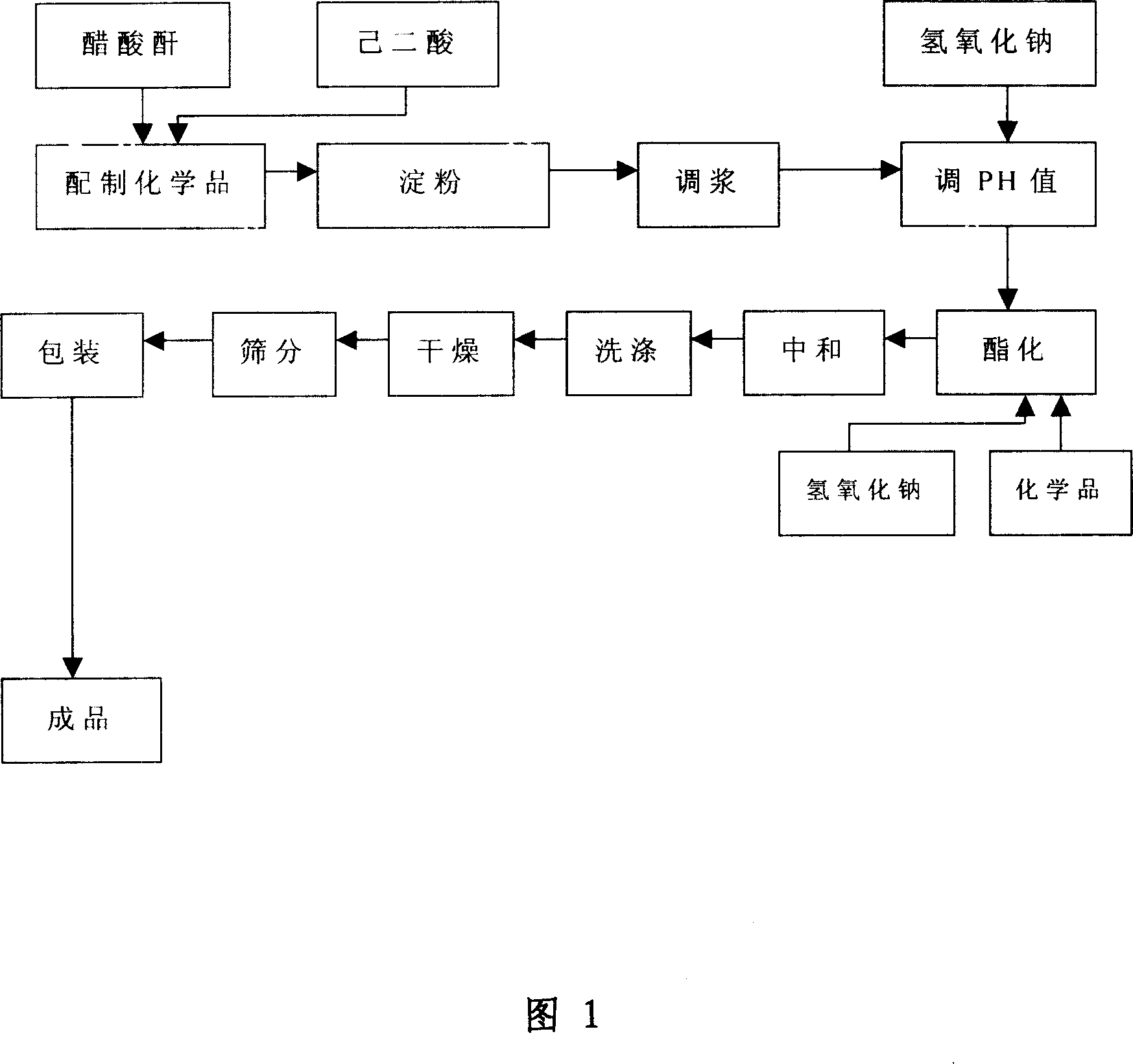

Image

Examples

Embodiment 1

[0021] First, fully dissolve 40 kg of acetic anhydride and 1 kg of adipic acid in a water bath at 60°C, cool to room temperature for later use, then add 1,000 kg of waxy starch and 1,800 kg of water into the reactor to form a 20-23 Be starch slurry, and keep stirring , add sodium hydroxide solution with a mass concentration of 3 to 3.8% to the kettle to adjust the pH value to 9.5, add the prepared chemicals, keep the temperature at 20±1°C to make it react, and continuously add the mass concentration dropwise during the reaction process It is a 3-3.8% sodium hydroxide solution, maintain a pH value of 8.5, continue to react for 1 hour after the addition of the prepared chemicals, add a mass concentration of 8-10% hydrochloric acid solution to neutralize to a pH value of 6.0-7.0, first Wash with a cyclone washer, then dehydrate with a scraper centrifugal dehydrator until the water content is ≤45%, and then dry it with an airflow dryer to make the water content ≤14.0%. The dried st...

Embodiment 2

[0023] The steps are the same as in Example 1, except that tapioca starch is used as raw material, the pH value of the esterification process is maintained at 8.0, and the reaction temperature is maintained at 20±1°C.

Embodiment 3

[0025] The steps are the same as in Example 1, except that the chemical ratio is: 40 kg of acetic anhydride and 2 kg of adipic acid, the pH value of the esterification process is maintained at 8.5, and the reaction temperature is maintained at 25±1°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com