Environmental-protection treatment technology of mineral oil waste

A waste and mineral oil technology, applied in the petroleum industry, processing hydrocarbon oil, dehydrating/demulsification by chemical methods, etc., can solve problems such as waste of resources, environmental pollution, water ecosystem damage, etc. Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of tapioca acetylated distarch adipate starch:

[0027] Weigh a certain amount of adipic anhydride and 20mL acetic anhydride and put them in a stoppered Erlenmeyer flask, dissolve them evenly in a water bath at 60°C, weigh 500g of tapioca starch (water content 12-14%) and dissolve them in pure water. Make starch milk with a concentration of 40%, raise the temperature to 30°C, adjust the pH of the starch milk to 8.0-8.5 with 3.0% sodium hydroxide solution, and add the above-mentioned medicines dropwise within a certain period of time at room temperature until the pH remains unchanged , adjust the pH of the system to about 5.0-5.5 with dilute hydrochloric acid (10%), terminate the reaction, vacuum filter, dehydrate, wash with water three times, and dry at normal temperature to obtain cassava acetylated distarch adipate starch.

Embodiment 2

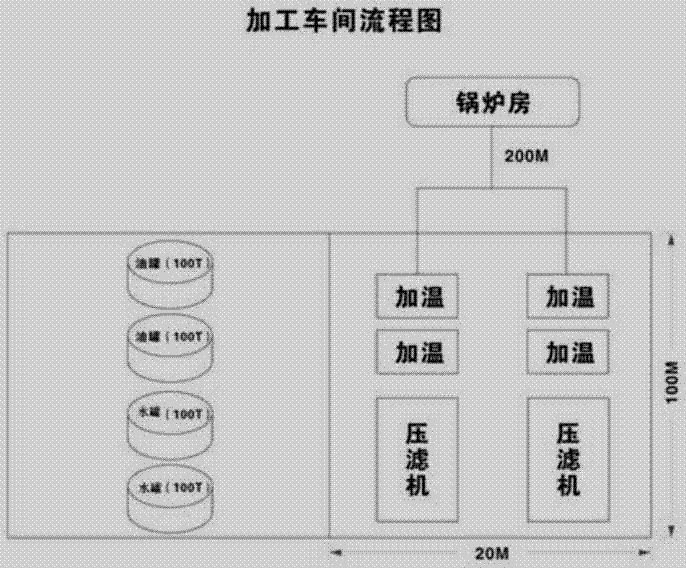

[0029] A mineral oil waste treatment process:

[0030] (1) Processing chemicals: According to the weight fraction, use 50 parts of SPX-8603 demulsifier, 35 parts of polyacrylamide, and 8 parts of sodium silicate to heat to 400 degrees to dissolve and react for 1 hour to form a transparent liquid and pack it into a barrel for later use ;

[0031] (2) First put the mineral oil waste into the heating tank, add 0.5% of each ton of mineral oil waste into the medicament and heat it to about 80 degrees and stir fully to make the mineral oil waste demulsify, decompose, and precipitate 2 The crude oil, waste water and impurities are squeezed out through the filter press in an hour, and the water is filtered out, and the impurities form powdery solids.

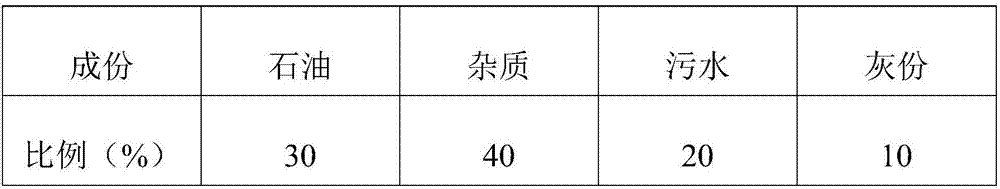

[0032] Comparison of parameters before and after mineral oil waste treatment:

[0033] The oil and impurities processed by this technology have been tested by professional inspection agencies, and all of them have reached the emission...

Embodiment 3

[0039] A mineral oil waste treatment process:

[0040] (1) Processing chemicals: According to the weight fraction, use 50 parts of ZSP9201 demulsifier, 35 parts of polyacrylamide, and 8 parts of sodium silicate to heat to 400 degrees to dissolve and react for 1 hour to form a transparent liquid and pack it into a barrel for later use;

[0041] (2) First put the mineral oil waste into the heating tank, add 0.5% of each ton of mineral oil waste into the medicament and heat it to about 80 degrees and stir fully to make the mineral oil waste demulsify, decompose, and precipitate 2 The crude oil, waste water and impurities are squeezed out through the filter press in an hour, and the water is filtered out, and the impurities form powdery solids.

[0042] Comparison of parameters before and after mineral oil waste treatment:

[0043] The oil and impurities processed by this technology have been tested by professional inspection agencies, and all of them have reached the emission st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com