Treatment method for waste salt water generated in production process of polycarbonate

A production process, polycarbonate technology, applied in the direction of neutralization of water/sewage treatment, filtration treatment, natural water treatment, etc., can solve the problem of low removal rate of ammonia nitrogen and chemical oxygen demand COD, adsorbent mixed into the wastewater system, adsorbent Complicated preparation and other problems, to achieve the effect of low investment cost of industrialization, avoid secondary pollution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

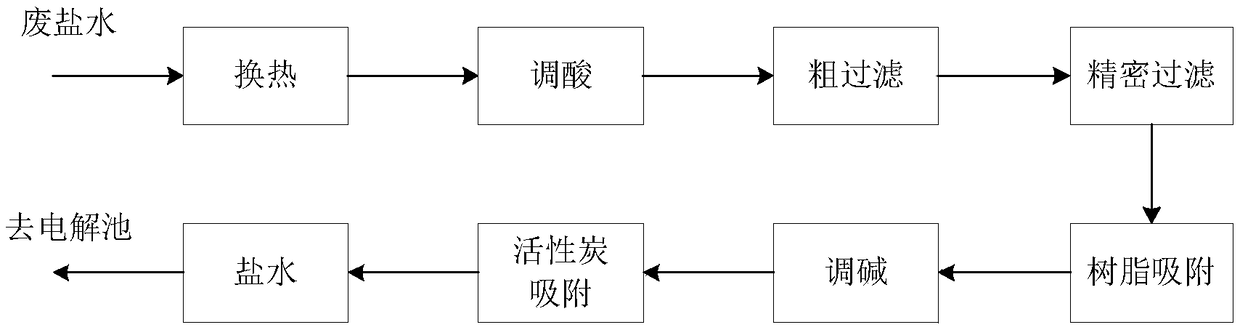

[0034] The concrete technological process of the treatment method of the waste brine produced in the polycarbonate production process of the present invention is as follows figure 1 shown.

[0035] In the first step, the waste brine generated in the PC production process is adjusted to 50°C by a heat exchanger, and then sampled and analyzed; among them, the pH value is about 11, the content of sodium chloride is 9.83%, the content of sodium carbonate is 1.36%, bisphenol A And the total content of p-tert-butylphenol is 210ppm, quaternary ammonium salt is 19ppm, TOC is 173ppm, TN is 5.4ppm;

[0036] In the second step, the above-mentioned waste brine is introduced into 1.5m 3 to the 80% liquid level, add hydrochloric acid with a mass percentage concentration of 30%, start stirring to adjust the pH value of the waste brine in the acid-adjusting kettle to 3, then turn on the feed pump P910, and pass through the 200-mesh coarse filter in turn And 5 micron precision filter to remo...

Embodiment 2

[0042] The first step, with embodiment 1;

[0043] In the second step, the waste brine treated in the first step is introduced into 1.5m 3to the 80% liquid level, add hydrochloric acid with a mass percentage concentration of 30%, start stirring to adjust the pH value of the waste brine in the acid-adjusting kettle to 2; then turn on the feed pump P910, and pass through the 100-mesh coarse filter in turn and 10 micron precision filter, all transported to the high tank;

[0044] In the third step, the waste brine in the head tank enters the macroporous resin adsorption column for adsorption by gravity flow (the diameter of the adsorbent is 300mm, and the height is 900mm), and the flow rate of the waste brine is controlled by a flow meter to 0.2m 3 / h (ie flow rate 3BV / h), the adsorption time is 20min, and the adsorption temperature is controlled at 20-60°C;

[0045] In the fourth step, the absorbed waste brine enters the alkali-adjusting kettle, and a 10% sodium hydroxide solu...

Embodiment 3

[0049] The first step, with embodiment 1;

[0050] In the second step, the waste brine treated in the first step is introduced into 1.5m 3 to the 80% liquid level, add hydrochloric acid with a mass percentage concentration of 30%, start stirring to adjust the pH value of the waste brine in the acid-adjusting kettle to 2; then turn on the feed pump P910, and pass through the 100-mesh coarse filter in turn and 5 micron precision filter, all transported to the high tank;

[0051] In the third step, the waste brine in the head tank enters the macroporous resin adsorption column for adsorption by gravity flow (the diameter of the adsorbent is 100mm, and the height is 300mm), and the flow rate of the waste brine is controlled by a flowmeter to 120mL / h (ie, the flow rate is 3BV / h). , the adsorption time is 20min; the adsorption temperature is controlled at 20-60°C;

[0052] In the fourth step, the absorbed waste brine enters the alkali-adjusting kettle, and a 10% sodium hydroxide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com