Preparation method of rosin modified phenolic resin

A technology for modifying phenolic resin and rosin, which is applied in the field of phenolic resin, can solve the problems of poor solubility of rosin-modified phenolic resin, and achieve the effects of effective control of resin viscosity, good oil solubility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

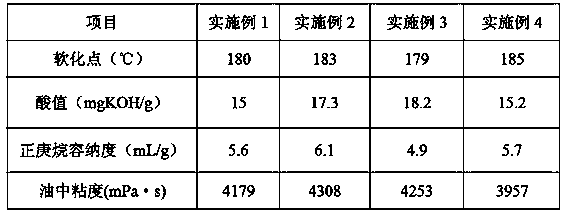

Examples

Embodiment 1

[0013] Add 3 kg of cresol and 30 g of anhydrous aluminum trichloride to the reaction kettle, raise the temperature to 60°C, add 1.2 kg of solid formaldehyde while stirring, adjust the solution to alkaline, raise the temperature to 100°C, and react for 5 hours; Add 9 kg of rosin to the kettle, heat up to 155°C, and react for 4.5 hours; add 1.5 kg of sorbitol and 10 g of metaphosphoric acid to the reactor, heat up to 200°C, react for 2 hours, continue to heat up to 230°C, and react for 2 hours to obtain Rosin modified phenolic resin.

Embodiment 2

[0015] Add 40 kg of dodecylphenol and 400 g of anhydrous aluminum trichloride to the reaction kettle, raise the temperature to 60°C, add 12 kg of solid formaldehyde while stirring, adjust the solution to alkaline, raise the temperature to 115°C, and react for 4 hours Add 95 kilograms of rosin in the reactor, heat up to 150 ° C, react for 4.5 hours; add 15 kg of xylitol and 200 grams of metaphosphoric acid in the reactor, heat up to 190 ° C, react for 2 hours, continue to heat up to 240 ° C, react After 1 hour, a rosin-modified phenolic resin was obtained.

Embodiment 3

[0017] Add 35 kg of p-tert-butylphenol and 300 g of anhydrous aluminum trichloride to the reaction kettle, raise the temperature to 65°C, add 10 kg of solid formaldehyde while stirring, adjust the solution to alkaline, raise the temperature to 110°C, and react for 4.5 hours Add 100 kilograms of rosin in the reactor, heat up to 145 ° C, react for 4.5 hours; add 17 kg of pentaerythritol and 150 grams of metaphosphoric acid in the reactor, heat up to 180 ° C, react for 2.5 hours, continue to heat up to 235 ° C, react for 1.5 hours, to obtain rosin-modified phenolic resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com