Industrial continuous process for preparation of p-tert-butylphenol

A technology of p-tert-butylphenol and phenol, which is applied in the field of preparation of tert-butylphenol and continuous industrialization, can solve the problems of low conversion rate, difficult treatment, difficult product separation, etc., and achieve high conversion rate, good selectivity and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

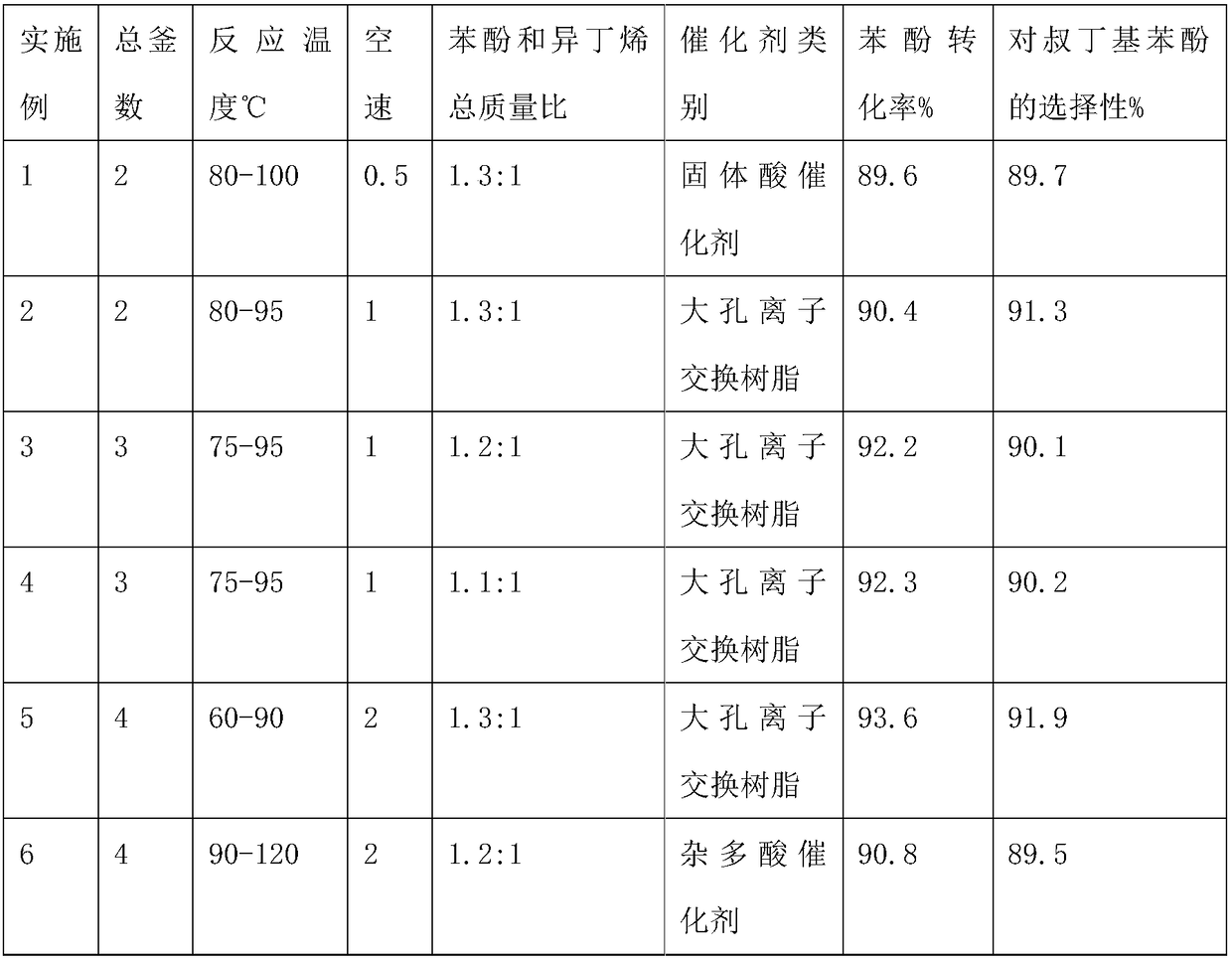

Examples

Embodiment 1

[0013] Embodiment 1: With phenol and isobutylene as raw materials, under the action of catalyst, the fixed-bed reactor that is continuously operated in series by multiple kettles, the reactor is a fixed-bed reactor operated continuously in series with multiple kettles, and the catalyst filling capacity of the reactor accounts for 50% of the volume, the number of multiple reactors connected in series is 2, phenol is added from the first reactor, isobutene is added continuously through multiple reactors, the ratio of phenol and isobutene in each reactor is 1:0.3, and each reactor The reaction temperature range is: 60°C, the reaction pressure is 0MPa, the quality control rate is: 0.5, the reaction device is directly connected to the rectification device to separate the raw material and the product, the raw material is returned to the catalytic tower to complete the continuous operation, and the product is rectified Connects directly to product tank.

Embodiment 2

[0014] Embodiment 2: With phenol and isobutylene as raw materials, under the action of catalyst, the fixed-bed reactor of multi-still series continuous operation, the reactor is the fixed-bed reactor of multi-still series continuous operation, and the catalyst filling capacity of the reactor accounts for 80% of the volume, the number of multiple reactors connected in series is 4, phenol is added from the first reactor, isobutene is added continuously through multiple reactors, the ratio of phenol and isobutene in each reactor is 1:1, each reactor The reaction temperature range is: 180°C, the reaction pressure is 3.0MPa, and the quality control rate is: 3.0. The reaction device is directly connected to the rectification device to separate the raw material and the product, and the raw material is returned to the catalytic tower to complete the continuous operation. Distillation is connected directly to the product storage tank.

Embodiment 3

[0015] Embodiment 3: With phenol and isobutylene as raw materials, under the action of catalyst, through the fixed-bed reactor of continuous operation of multi-still series, the reactor is a fixed-bed reactor of multi-kettle series continuous operation, and the catalyst filling capacity of reactor accounts for 60% of the volume, the number of multiple reactors connected in series is 6, phenol is added from the first reactor, isobutene is added continuously through multiple reactors, and the ratio of phenol and isobutene in each reactor is 1:0.5, and each reactor The reaction temperature range is: 120°C, the reaction pressure is 2.0MPa, and the quality control rate is: 2.0. The reaction device is directly connected to the rectification device to separate the raw material and the product, and the raw material is returned to the catalytic tower to complete the continuous operation. Distillation is connected directly to the product storage tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com