System and method for separating carbon and electrolyte in aluminum electrolysis carbon slag

An electrolyte and aluminum electrolysis technology, applied in the field of aluminum electrolysis, can solve the problems of long roasting time, unfavorable large-scale treatment of carbon slag, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

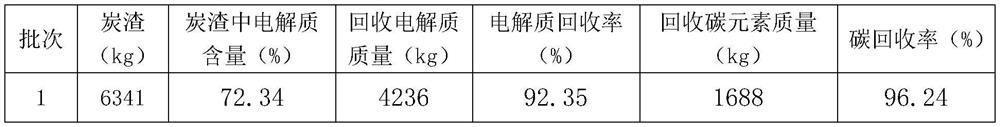

Embodiment 1

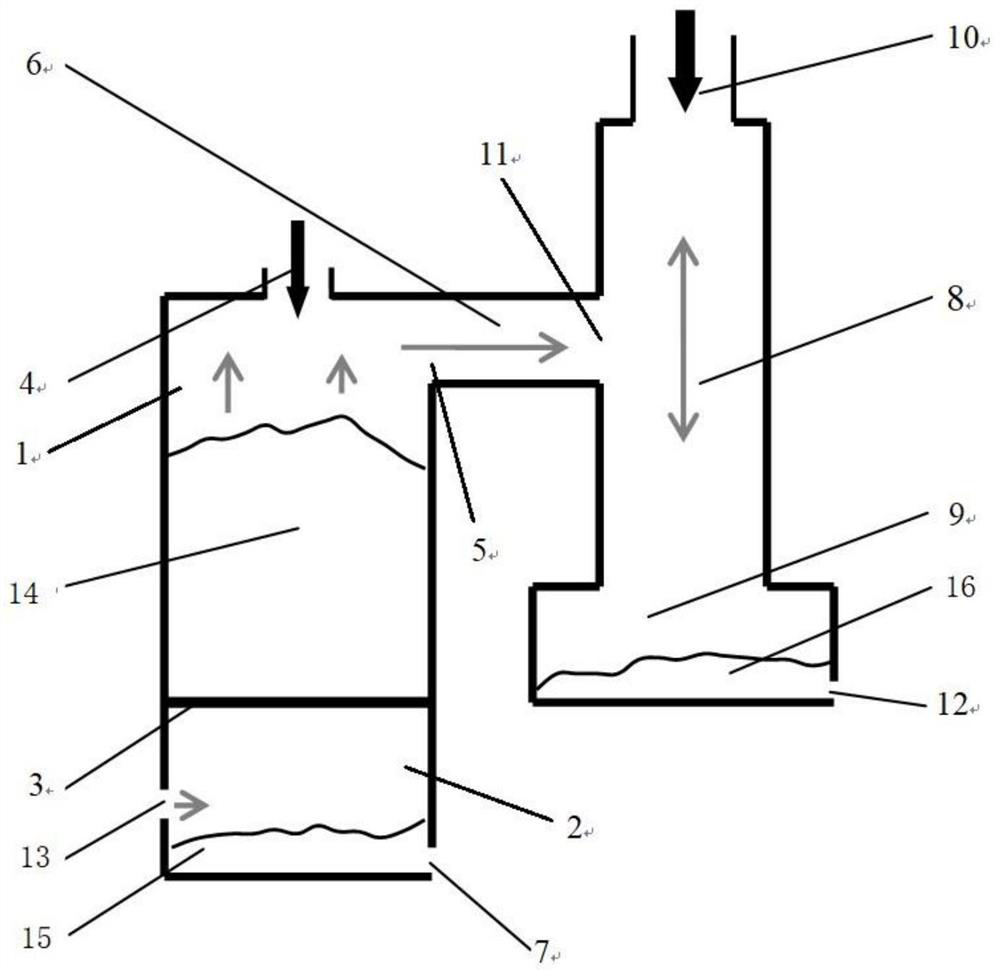

[0024] A system for separating carbon and electrolyte from aluminum electrolytic carbon residue, including a carbon residue heating and volatilization system, a high-temperature flue gas channel, and a gaseous electrolyte collection system; the carbon residue heating and volatilization system includes a volatilization chamber 1 and a low-fluorine The charcoal slag bin 2, the grid-shaped carbon electrode 3 is arranged between the volatilization bin 1 and the low-fluorine carbon slag bin 2, the charcoal slag feed port 4 is arranged on the top of the volatilization bin 1, and the upper part of the volatilization bin 1 has a flue gas outlet 5. It communicates with the high-temperature flue gas channel 6; the side of the low-fluorine carbon slag bin 2 has an inert gas inlet 13, and the lower part of the side has a low-fluorine carbon slag discharge port 7; the gaseous electrolyte collection system includes a collection bin 8 arranged from top to bottom and the material bin 9 for alu...

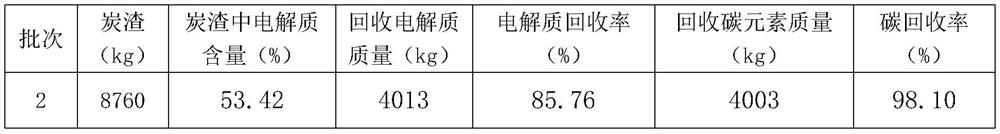

Embodiment 2

[0038]A system for separating carbon and electrolyte in aluminum electrolytic carbon slag, including a carbon slag heating and volatilization system, a high-temperature flue gas channel, and a gaseous electrolyte collection system; the carbon slag heating and volatilization system includes a volatilization chamber 1 and Low-fluorine carbon slag bin 2, a grid-shaped carbon electrode 3 is set between the volatilization bin 1 and the low-fluorine carbon slag bin 2, a carbon slag feed port 4 is provided on the top of the volatilization bin 1, and a flue gas outlet 5 is provided on the upper side of the volatilization bin 1 , which communicates with the high-temperature flue gas channel 6; the side of the low-fluorine carbon slag bin 2 has an inert gas inlet 13, and the lower part of the side has a low-fluorine carbon slag discharge port 7; the gaseous electrolyte collection system includes a collection system arranged from top to bottom The bin 8 and the material bin 9 for aluminum...

Embodiment 3

[0053] A system for separating carbon and electrolyte in aluminum electrolytic carbon slag, including a carbon slag heating and volatilization system, a high-temperature flue gas channel, and a gaseous electrolyte collection system; the carbon slag heating and volatilization system includes a volatilization chamber 1 and Low-fluorine carbon slag bin 2, a grid-shaped carbon electrode 3 is set between the volatilization bin 1 and the low-fluorine carbon slag bin 2, a carbon slag feed port 4 is provided on the top of the volatilization bin 1, and a flue gas outlet 5 is provided on the upper side of the volatilization bin 1 , which communicates with the high-temperature flue gas channel 6; the side of the low-fluorine carbon slag bin 2 has an inert gas inlet 13, and the lower part of the side has a low-fluorine carbon slag discharge port 7; the gaseous electrolyte collection system includes a collection system arranged from top to bottom The bin 8 and the material bin 9 for aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com