Microwave activation of coal gangue to prepare geopolymer material and method thereof

A technology of microwave activation and coal gangue, which is applied in the comprehensive utilization of solid waste and the field of materials, can solve the problems of high comprehensive cost, insignificant economic benefits, and large fluctuations, and achieve full recycling, which is conducive to the improvement of reaction ability and molding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

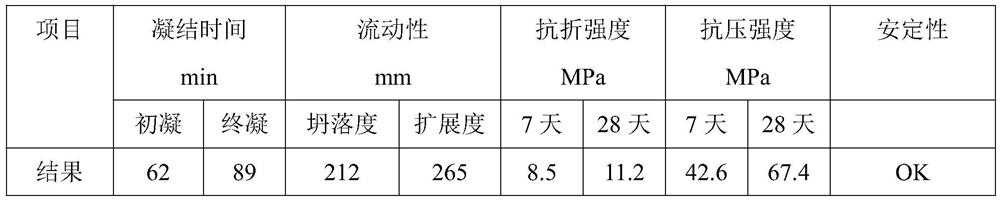

Embodiment 1

[0035] In the pretreatment of coal gangue, the coal gangue containing 32% C element is crushed with an impact crusher, and the coal gangue is crushed into gravel with a particle size of 10-30 mm and then enters a vertical high-pressure mill for grinding. In the process, 0.3% triethanolamine of the total weight of the raw coal gangue was added, and the specific surface area of the grinding and discharging material was 350 m2 / kg; then it was processed in a microwave processor, and the temperature reached 700 ° C after microwave treatment for 30 minutes. The coal gangue of C element can be kept at 650-680℃ for spontaneous combustion, and the temperature is maintained for 3.5 hours with the assistance of microwaves before discharging; Enter the vertical high-pressure mill for secondary grinding at room temperature + 50 °C, and finally obtain powder with a specific surface area of 420㎡ / kg. The powder obtained above is uniformly mixed according to the ratio of heat-treated coal ...

Embodiment 2

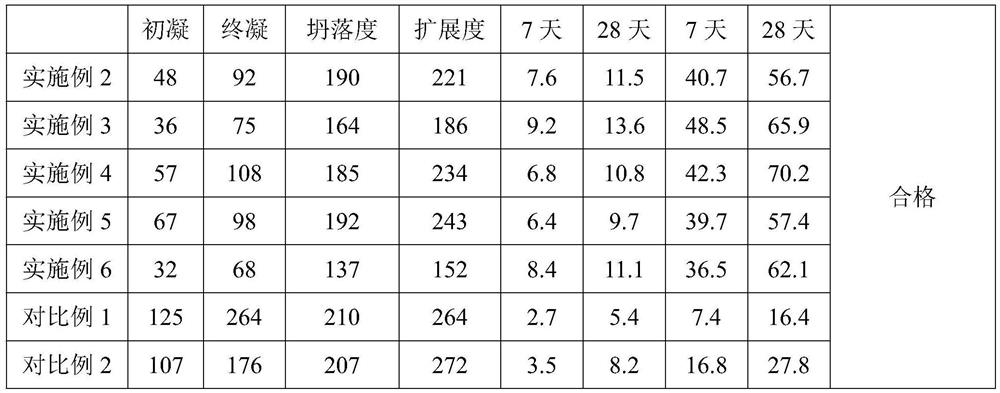

[0040] The pretreatment method is the same as in Example 1. In the grinding process, 0.5% of the total weight of the raw coal gangue is added with triethanolamine, and the content of C element in the coal gangue is 12%, because the content of C element is not enough to maintain the coal gangue powder in the range of 600 to 800 ° C. Therefore, 50kg of manganese dioxide was added to the microwave processor as an auxiliary heating material. After 1.5 hours of pre-treatment in the microwave treatment, the microwave treatment state was maintained, and the heat treatment temperature was maintained at 750 ± 60 °C to heat the coal gangue. The time was 2.5 hours, the final discharge temperature was 725°C, the cooling treatment and the secondary grinding treatment were the same as those in Example 1, and finally a powder with a specific surface area of 450 m2 / kg was obtained.

Embodiment 3

[0042] Others were the same as in Example 2, 65kg of ferric oxide was added to the microwave processor as an auxiliary heating material, the microwave pretreatment time was 1 hour, the maintenance temperature was 700 ± 50 ° C, the time was 3 hours, and the final discharge temperature was 675 ℃, the specific surface area after secondary grinding is 520㎡ / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com