A method for collaborative resource utilization of carbide slag and fly ash

A technology of fly ash and carbide slag, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of low comprehensive utilization efficiency of resources, low added value of products, and high requirements for equipment materials, so as to facilitate industrialization promotion , low equipment requirements, uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Al in the main chemical composition in the fly ash in this embodiment 2 o 3 , SiO 2 , TFe, loss on ignition accounted for 28.08%, 52.65%, 5.1% and 17.32% respectively; Ca(OH) in the chemical composition of carbide slag 2 Content 90%.

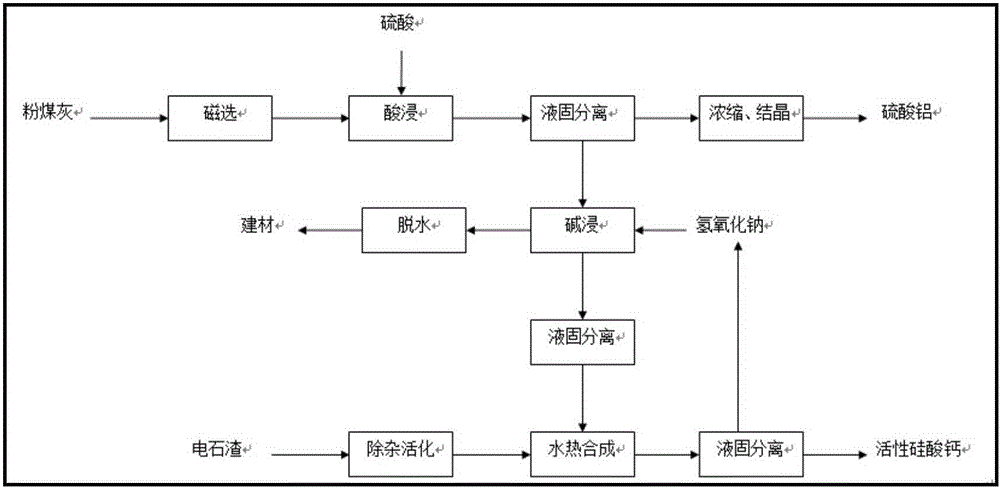

[0040] The method for collaborative resource utilization of calcium carbide slag and fly ash of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0041] 1) Fly ash magnetic separation deferrization pretreatment, the current intensity of the high gradient magnetic separator is 10A, and the magnetic field intensity is 0.8T.

[0042] 2) Under the condition of 80-150°C, leaching the de-ironized fly ash with a mass fraction of 50% sulfuric acid solution for 2 hours, the total amount of sulfuric acid is calculated according to the liquid-solid ratio = 0.8 (ml / g), after the reaction is completed Filter aluminum sulfate solution and acid leaching residue.

[0043] 3) After adjust...

Embodiment 2

[0050] Al in the main chemical composition in the fly ash in this embodiment 2 o 3 , SiO 2 , TFe, loss on ignition accounted for 28.08%, 52.65%, 5.1% and 17.32% respectively; Ca(OH) in the chemical composition of carbide slag 2 Content 90%.

[0051] The method for collaborative resource utilization of calcium carbide slag and fly ash of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0052] 1) Fly ash magnetic separation deferrification pretreatment, the current intensity of the high gradient magnetic separator is 10A, and the magnetic field intensity is 1.1T.

[0053] 2) Under the condition of 80-150°C, leaching the de-ironized fly ash with a mass fraction of 60% sulfuric acid solution for 4 hours, the total amount of sulfuric acid is calculated according to the liquid-solid ratio = 1.2 (ml / g), after the reaction is completed Filter aluminum sulfate solution and acid leaching residue.

[0054] 3) After adju...

Embodiment 3

[0061] Al in the main chemical composition in the fly ash in this embodiment 2 o 3 , SiO 2 , CaO, TFe, loss on ignition accounted for 25.1%, 46.5%, 18.7%, 2.9% and 16.32% respectively; Ca(OH) in the chemical composition of carbide slag 2 Content 92%.

[0062] The method for collaborative resource utilization of calcium carbide slag and fly ash of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0063] 1) Fly ash magnetic separation deferrization pretreatment, the current intensity of the high gradient magnetic separator is 10A, and the magnetic field intensity is 1.0T.

[0064] 2) Under the condition of 80-150°C, leaching the de-ironized fly ash with a mass fraction of 60% sulfuric acid solution for 4 hours, the total amount of sulfuric acid is calculated according to the liquid-solid ratio = 1.2 (ml / g), after the reaction is completed Filter aluminum sulfate solution and acid leaching residue.

[0065] 3) Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com