Suaeda-salsa-base porous carbon and application thereof

A technology of Suaeda salsa and porous carbon, applied in inorganic chemistry, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems that have not yet been reported, achieve important social significance and strong industrial operability , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

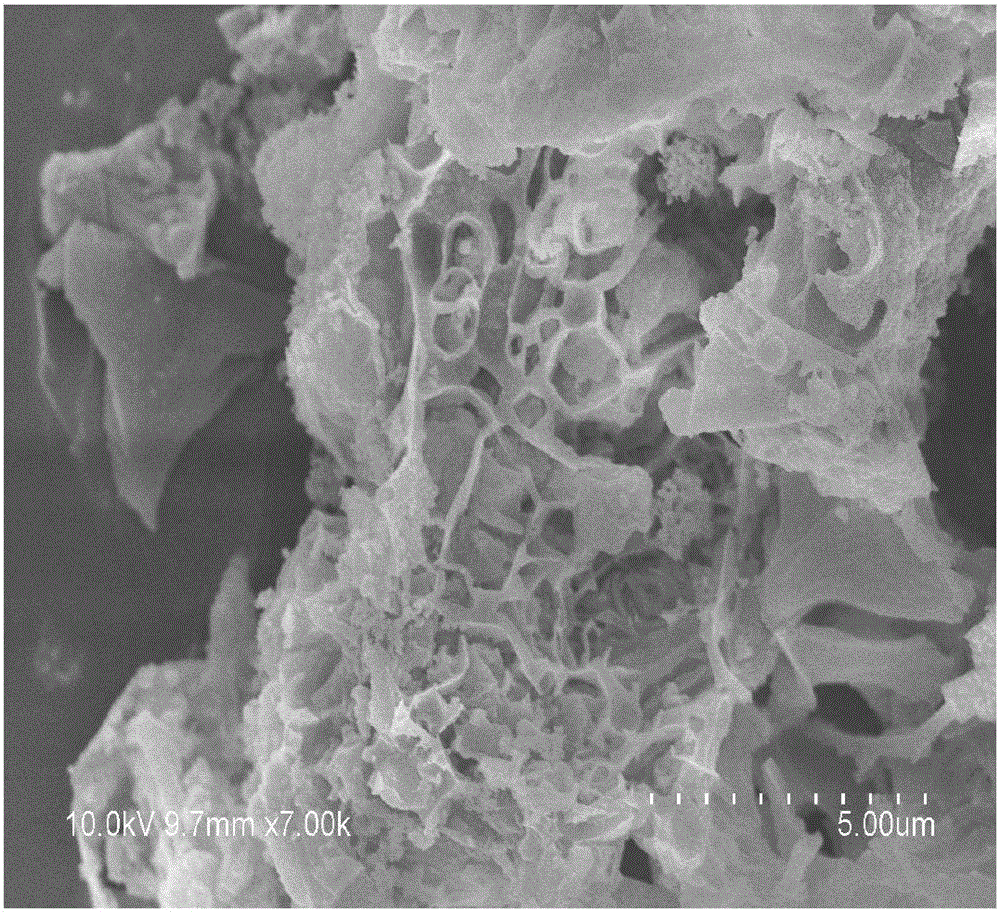

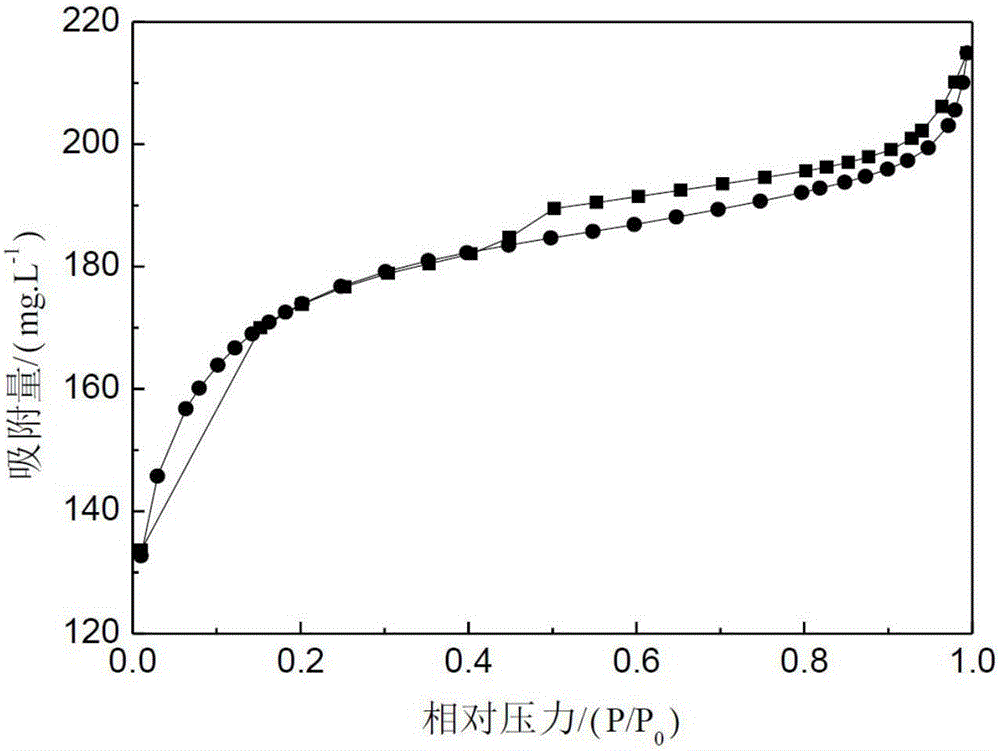

[0034] A kind of Suaeda salsa base porous carbon, it is prepared by following method:

[0035] (1) In early December 2015, the mature Suaeda salsa was collected, washed with water, dried naturally until the water content was 10%, and crushed to 150 mesh. It was determined that the sodium content in the Suaeda salsa plant was 2.67 mg / g, and the potassium content was 3.24 mg / g.

[0036] (2) Weigh 20g of Suaeda salsa powder and place it in a tube furnace, under the protection of nitrogen, raise the temperature to 700°C at a rate of 12°C / min, and keep the constant temperature for 180min.

[0037] (3) Naturally cool to room temperature under the condition of nitrogen gas flow, and wash with 500 mL of 60°C mixed acid (containing 10% hydrochloric acid and 7% hydrofluoric acid) by shaking for three times, each time for 30 minutes. After filtering, wash with hot deionized water until the pH value is 7.0 (no chlorine ion is detected), and dry to obtain the Suaeda salsa-based porous car...

Embodiment 2

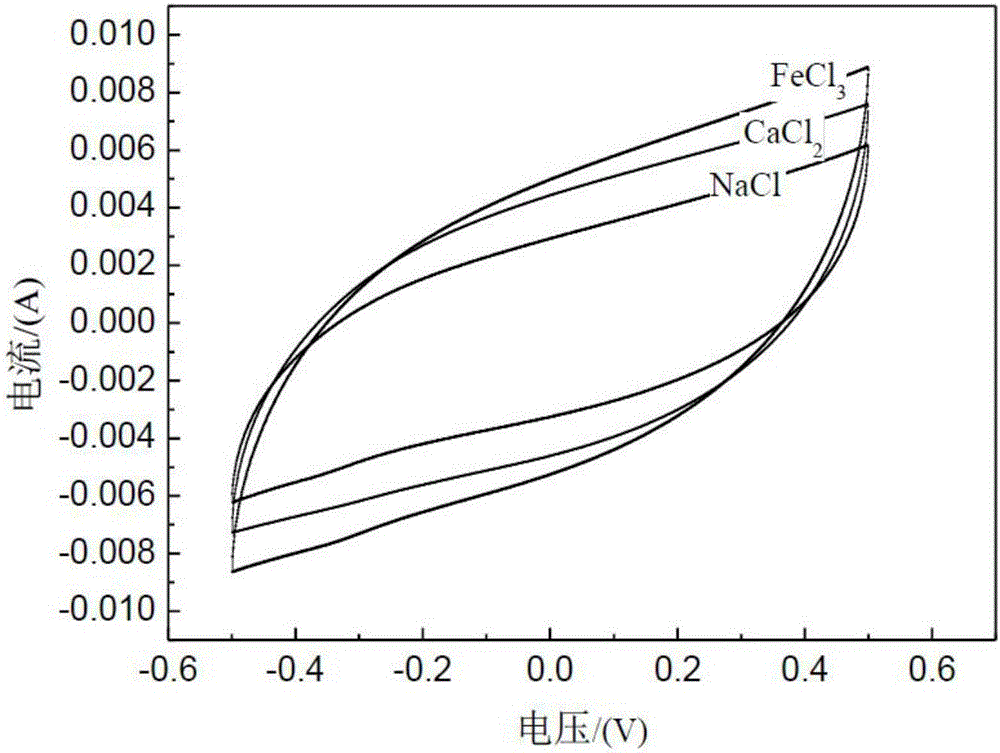

[0040] Capacitive deionization applications of Suaeda-based porous carbons in saline. Mix the Suaeda-based porous carbon material prepared in the above-mentioned Example 1 with acetylene black and polytetrafluoroethylene at a mass ratio of 8:1:1, add it to the ethanol dispersant, and disperse it ultrasonically until it is evenly distributed. Spread evenly on the graphite plate, and dry overnight at 105°C to form a porous carbon electrode. Then take two porous carbon electrodes of the same quality, separate them with plastic nets of the same size, connect the two ends of the electrodes with a DC power supply, and inject the solution to be deionized into a single capacitor. In 0.5mol / L sodium chloride, calcium chloride and ferric chloride solution, the specific capacitance of Suaeda-based porous carbon in saline land is 88F / g, 94F / g and 112F / g respectively. In a 1mol / L sodium chloride solution, under the test voltage range of -0.5 to 0.5V, the constant current charge and discha...

Embodiment 3

[0043] A kind of Suaeda salsa base porous carbon, it is prepared by following method:

[0044] (1) In the first ten days of December 2015, the mature Suaeda salsa was collected, washed with water, dried naturally until the water content was 11%, and crushed to 200 mesh. It was determined that the sodium content in the Suaeda salsa plant was 2.69 mg / g, and the potassium content was 3.26 mg / g.

[0045] (2) Weigh 20g of Suaeda salsa powder and place it in a tube furnace. Under the protection of nitrogen, the heating rate is raised to 800°C at a rate of 15°C / min, and the temperature is kept at a constant temperature for 240min.

[0046] (3) Naturally cool to room temperature under the condition of nitrogen gas flow, and wash with 500 mL of 70°C mixed acid (containing 12% hydrochloric acid and 8% hydrofluoric acid) by shaking for three times, each time for 30 minutes. After filtering, wash with hot deionized water until the pH value is 7.0 (no chlorine ion is detected), and dry to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com