Method for preparing pseudo-boehmite co-preparation white carbon black by coal gangue

A technology of pseudo-boehmite and coal gangue, which is applied in the field of co-production of pseudo-boehmite and co-production of white carbon black by using coal gangue, which can solve the problems of high raw material cost, low resource utilization rate, environmental damage, etc., and achieve uniform particle size , high added value, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

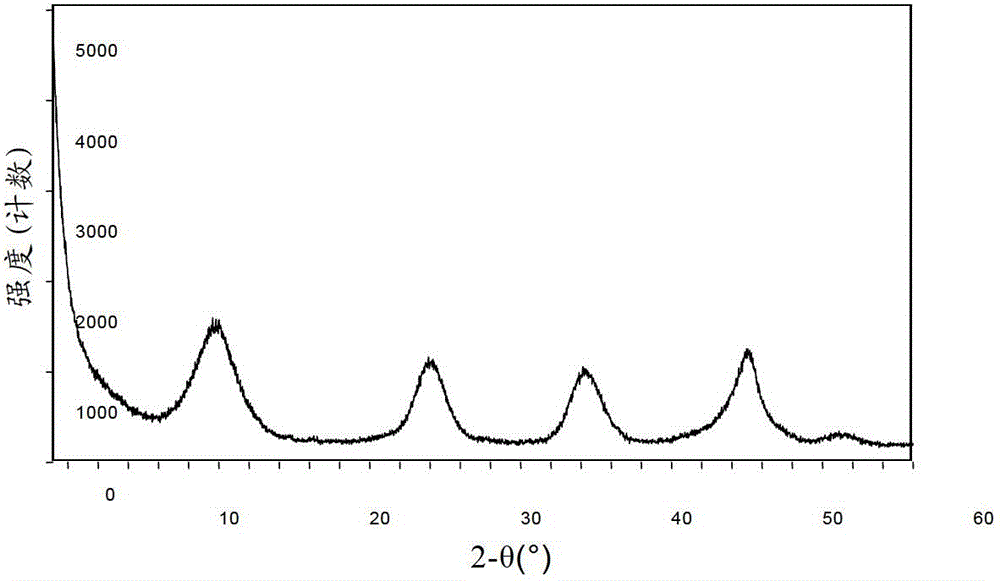

Image

Examples

Embodiment 1

[0042] In this example, the main mineral component of coal gangue is kaolinite, and the content of impurity minerals is extremely low; alumina, silica, and loss on ignition account for 40.08%, 37.65%, and 17.32%, respectively.

[0043] 1) Preparation of activated coal gangue powder: Weigh 50 grams of coal gangue, crush it into 50-300 mesh, grind it, remove impurities, roast it, and then naturally cool to obtain activated coal gangue powder;

[0044] 2) Alkali leaching desiliconization: put the above-mentioned activated coal gangue powder in a leaching device, and use a 20% mass fraction of dilute sodium hydroxide solution for 30 minutes at 90°C. The total amount of sodium hydroxide is as follows: Na 2 O: SiO 2 =1.0 mass ratio calculation, after the reaction is completed, filter to obtain sodium silicate solution and alkali leaching residue;

[0045] 3) Preparation of white carbon black:

[0046] a. Add sodium hexametaphosphate to the above sodium silicate solution, the qual...

Embodiment 2

[0054] Alumina, silica, and loss on ignition account for 37.36%, 42.79%, and 15.60% of the coal gangue used in this example, respectively.

[0055] 1) Preparation of activated coal gangue powder: Weigh 50 grams of coal gangue, crush it into 50-300 mesh, grind it, remove impurities, bake it at 800° C., and then cool it naturally to obtain activated coal gangue powder.

[0056] 2) Alkali leaching desiliconization: put the above-mentioned activated coal gangue powder in the leaching device, add 18% sodium hydroxide solution in two times for alkali leaching: add 50-80% of the total amount for the first time %, the alkali leaching time is 30~40 minutes; add the remaining sodium hydroxide solution for the second time, and the alkali leaching time is 20~30 minutes; the total amount of sodium hydroxide is based on Na 2 O: SiO 2 =1.1 mass ratio calculation, after the reaction is completed, filter to obtain sodium silicate solution and alkali leaching residue.

[0057] 3) Preparation ...

Embodiment 3

[0066] Alumina, silica, and loss on ignition account for 40.08%, 37.65%, and 17.32% of the coal gangue used in this example, respectively.

[0067] 1) Preparation of activated coal gangue powder: Weigh 50 grams of coal gangue, crush it into 50-300 meshes, grind it, remove impurities, bake it at 1000° C. and cool it naturally to obtain activated coal gangue powder;

[0068] 2) Alkali leaching desiliconization: put the above-mentioned activated coal gangue powder in the leaching device, add 15% sodium hydroxide solution in two times for alkali leaching: add 50-80% of the total amount for the first time %, the alkali leaching time is 30~40 minutes; add the remaining sodium hydroxide solution for the second time, and the alkali leaching time is 20~30 minutes; the total amount of sodium hydroxide is based on Na 2 O: SiO 2 =1.1 mass ratio calculation, after the reaction is completed, filter to obtain sodium silicate solution and alkali leaching residue.

[0069] 3) Preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com