Method for preparing calcium sulfate whiskers from acetylene sludge and waste sulfuric acid

A calcium sulfate whisker and waste sulfuric acid technology, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of low comprehensive utilization efficiency of resources, low added value of products, harsh production conditions, etc., and achieve convenient The effect of industrialization promotion, low equipment requirements and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Ca(OH) in the chemical composition of carbide slag in the present embodiment 2 Content 90%.

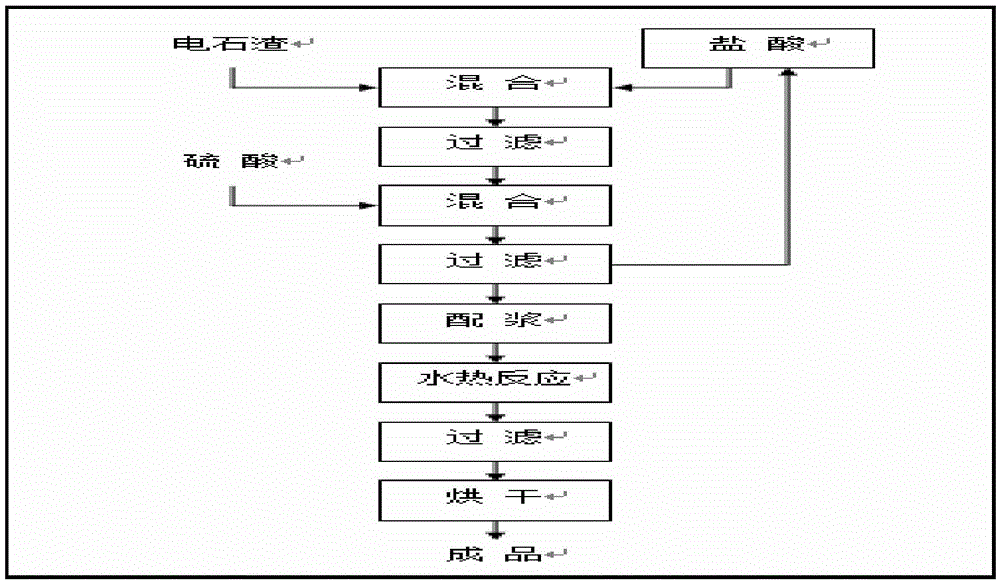

[0036] Carbide slag of the present invention and waste sulfuric acid prepare the method for calcium sulfate whisker, and its technological process is as follows figure 1 shown, including the following steps:

[0037] (1) Grinding the calcium carbide slag to 100 meshes, after sieving, it is prepared into a slurry with a mass percentage of 50%;

[0038] 2) The 3mol / L hydrochloric acid and the calcium oxide content in the calcium carbide slag slurry were mixed and reacted for 20 minutes at a molar ratio of 1.2:1. After the reaction was completed, the calcium chloride solution and acid leaching residue were obtained by filtering;

[0039] 3) After the waste sulfuric acid solution is decolorized and impurity-removed with activated carbon, it is prepared into a 9mol / L dilute sulfuric acid solution;

[0040] 4) Under the stirring condition of 200r / min, slowly drop the dilute sulfur...

Embodiment 2

[0046] Ca(OH) in the chemical composition of carbide slag in the present embodiment 2 Content 90%.

[0047] Carbide slag of the present invention and waste sulfuric acid prepare the method for calcium sulfate whisker, and its technological process is as follows figure 1 shown, including the following steps:

[0048] (1) Grinding the calcium carbide slag to 100 mesh, after sieving, it is prepared into a slurry with a mass percentage of 25%;

[0049] 2) 2mol / L hydrochloric acid and calcium oxide content in the calcium carbide slag slurry were mixed and reacted for 20 minutes by acid leaching at a molar ratio of 1.6:1. After the reaction was completed, calcium chloride solution and acid leaching slag were obtained by filtering;

[0050] 3) After the waste sulfuric acid solution is decolorized and impurity-removed with activated carbon, it is prepared into a 2mol / L dilute sulfuric acid solution;

[0051] 4) Under the stirring condition of 200r / min, slowly drop the dilute sulfur...

Embodiment 3

[0057] Ca(OH) in the chemical composition of carbide slag in the present embodiment 2 Content 90%.

[0058] Carbide slag of the present invention and waste sulfuric acid prepare the method for calcium sulfate whisker, and its technological process is as follows figure 1 shown, including the following steps:

[0059] (1) Grinding the calcium carbide slag to 200 meshes, after sieving, it is prepared into a slurry with a mass percentage of 25%;

[0060] 2) Mix 1 mol / L hydrochloric acid and calcium oxide content in the calcium carbide slag slurry with a molar ratio of 1.6:1 for acid leaching and mixed reaction for 30 minutes, and filter to obtain calcium chloride solution and acid leaching residue after the reaction is completed;

[0061] 3) After the waste sulfuric acid solution is decolorized and impurity-removed with activated carbon, it is prepared into a 3mol / L dilute sulfuric acid solution;

[0062] 4) Under the stirring condition of 120r / min, slowly drop the dilute sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com