Slow release compound fertilizer via phosphoric acid passivation of magnesium slag

A slow-release compound fertilizer and magnesium slag phosphoric acid technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as difficulty in large-scale promotion, limited slow-release effect, and difficulty in degradation, and achieve high-value comprehensive utilization, The effect of reducing fertilizer loss and easy production application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

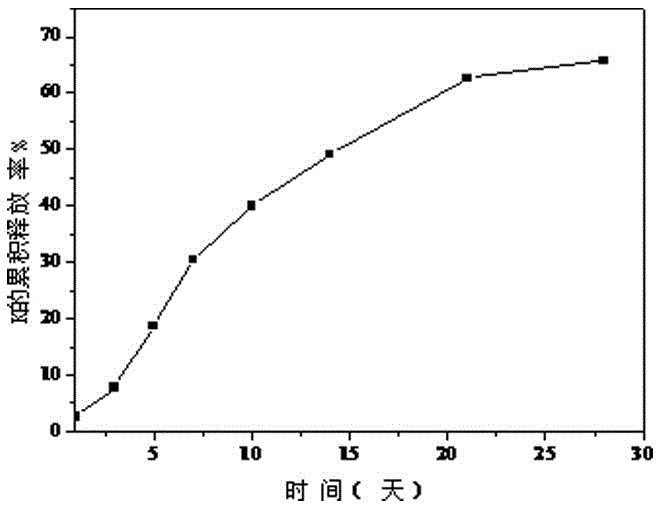

Embodiment 1

[0030] Weigh a certain amount of magnesium slag, urea, and industrial potassium sulfate and use a small grinder to grind them through an 80-mesh sieve for use, absorb 11.00mL of 85% phosphoric acid and add 5mL of water to dilute for use. Weigh 20g of magnesium slag powder passed through a 80-mesh sieve and put it into a beaker, pour the diluted phosphoric acid into the beaker, stir quickly with a glass rod to make the magnesium slag and phosphoric acid mix evenly and fully react, then add urea powder passed through an 80-mesh sieve 41.04g and 27.20g of industrial potassium sulfate powder, mix well, add 8mL water, mix and granulate in a disc granulator. Then it is taken out and dried to obtain the magnesium slag-based slow-release fertilizer. The slow-release performance of the magnesium slag-based slow-release fertilizer was measured by the water-soluble method, and the initial release rate of potassium was 2.60%, and the cumulative release rate in 28 days was 65.69%, which me...

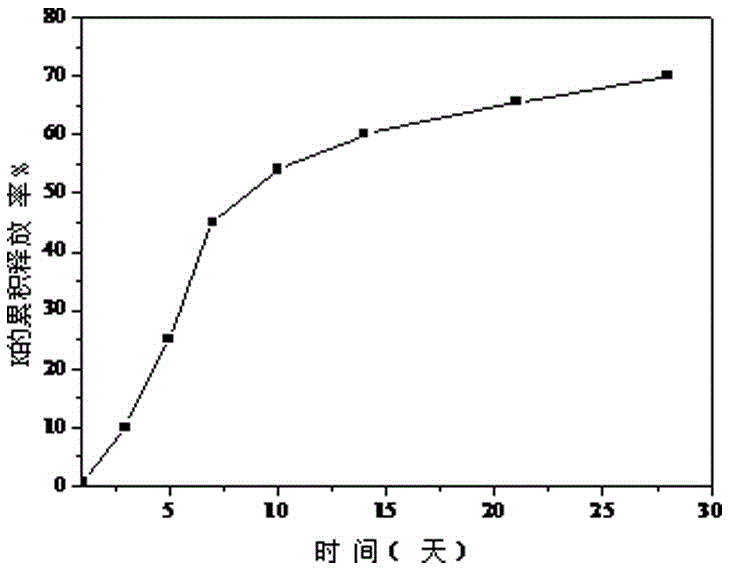

Embodiment 2

[0032]Suck and weigh a certain amount of magnesium slag, urea, and industrial potassium sulfate and use a small grinder to grind them through an 80-mesh sieve for use. Take 11.00mL of 85% phosphoric acid and add 5mL of water to dilute for use. Weigh 20g of magnesium slag powder passed through a 80-mesh sieve and put it into a beaker, pour the diluted phosphoric acid into the beaker, stir quickly with a glass rod to mix the magnesium slag and phosphoric acid evenly, and then add 41.04g of urea powder passed through an 80-mesh sieve and 27.20g of industrial potassium sulfate powder, mix well and add 8mL of water, mix and granulate in a disc granulator, then put the granules into a small coating machine, add 7g of cement, roll for a certain period of time, and use The constant temperature heater blows and dries the fertilizer. After the drying is completed, the binder (self-made organic binder) is sprayed into the coating machine, and then 8g of cement is added, and it is rotated ...

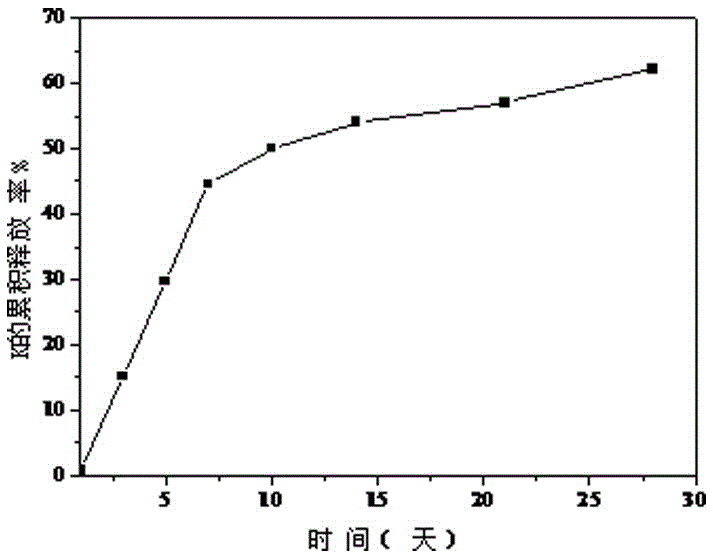

Embodiment 3

[0034] Weigh a certain amount of magnesium slag, urea, and industrial potassium sulfate and use a small grinder to grind them through an 80-mesh sieve for use, absorb 8.75mL of 85% phosphoric acid and add 5mL of water to dilute for use. Weigh 20g of magnesium slag powder passed through a 80-mesh sieve and put it into a beaker, pour the diluted phosphoric acid into the beaker, stir quickly with a glass rod to mix the magnesium slag and phosphoric acid evenly, and then add 41.04g of urea powder passed through an 80-mesh sieve and industrial potassium sulfate powder 27.20g, mix well, add 8mL water, and granulate in a disc granulator. After granulation, put it into a small coating machine, add 7g of magnesium slag, and after rolling for a certain period of time, use a constant temperature heater to blow dry the fertilizer. After drying, spray a binder (self-made organic binder) into the coating machine, and then Add 8g of magnesium slag, rotate for a certain period of time, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cumulative release rate | aaaaa | aaaaa |

| cumulative release rate | aaaaa | aaaaa |

| cumulative release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com