Method for producing krill oil, protein peptide powder and chitosan by full utilization of Antarctic krill powder

An Antarctic krill powder and krill production technology, applied in the direction of botanical equipment and methods, fat oil/fat production, application, etc., can solve the problems of large energy and resource consumption, backward technology, low resource utilization rate, etc., and achieve reduction The influence of harmful factors, the improvement of product purity, and the effect of removing harmful factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

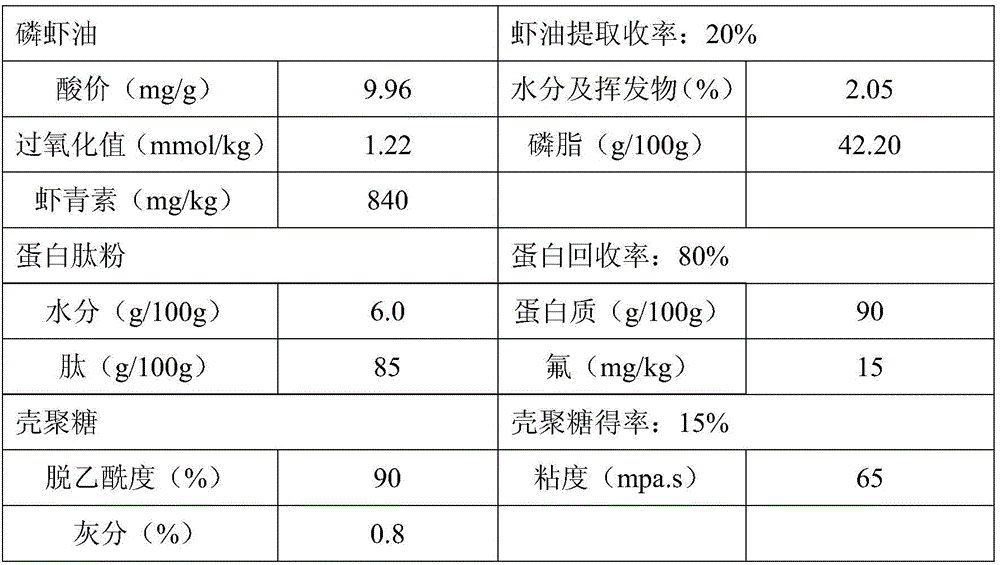

Embodiment 1

[0022] Antarctic krill powder fully utilizes the method of producing krill oil, protein peptide powder and chitosan, and the steps include:

[0023] (1) Extraction of krill oil: Add 50kg of shrimp powder to 250L of 95% alcohol for extraction, temperature 45-65°C, stir and extract for 90min, press filter with nitrogen or carbon dioxide to obtain residue and extract, add 150L of 95% alcohol to the residue for secondary Extraction, when the extract is evaporated under reduced pressure to an appropriate volume, centrifuged to remove impurities, evaporated and precipitated at low temperature and reduced pressure (45~65°C, -0.05~-0.10mPa) to obtain krill oil, and then add 75% alcohol for extraction and layering, The upper layer is recovered as the solvent for the next extraction, the lower layer is desolvated and concentrated, and the organic solvent is recovered by the recovery tower for reuse;

[0024] (2) Preparation of protein peptide powder: 36.5kg of degreased shrimp powder wa...

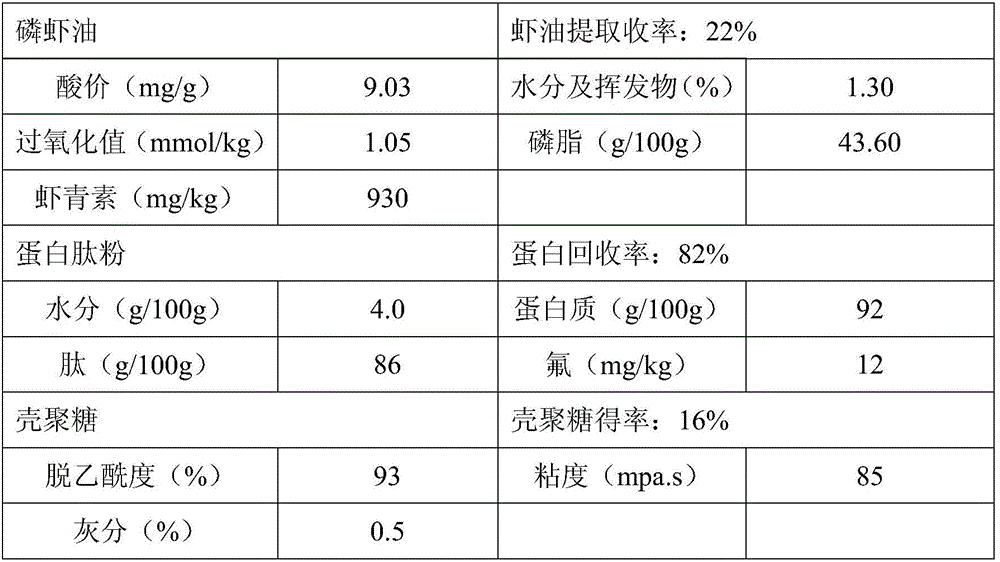

Embodiment 2

[0029] Antarctic krill powder fully utilizes the method of producing krill oil, protein peptide powder and chitosan, and the steps include:

[0030] (1) Extraction of krill oil: add 800L of 95% alcohol to extract 80kg of shrimp powder, extract at a temperature of 45-65°C, and extract for 180 minutes. Press filter with nitrogen or carbon dioxide to obtain the residue and extract, and add 200L of 95% alcohol to the residue for secondary extraction , when the extract is evaporated to an appropriate volume under reduced pressure, it is centrifuged to remove impurities, evaporated and precipitated at low temperature and reduced pressure (45~65°C, -0.05~-0.10mPa) to obtain krill oil, and then add 95% alcohol to extract and layer, the upper layer Recover as the solvent for the next extraction, the lower layer is precipitated and concentrated, the extraction and stratification steps are repeated twice, and the organic solvent is recovered by the recovery tower for reuse;

[0031] (2) ...

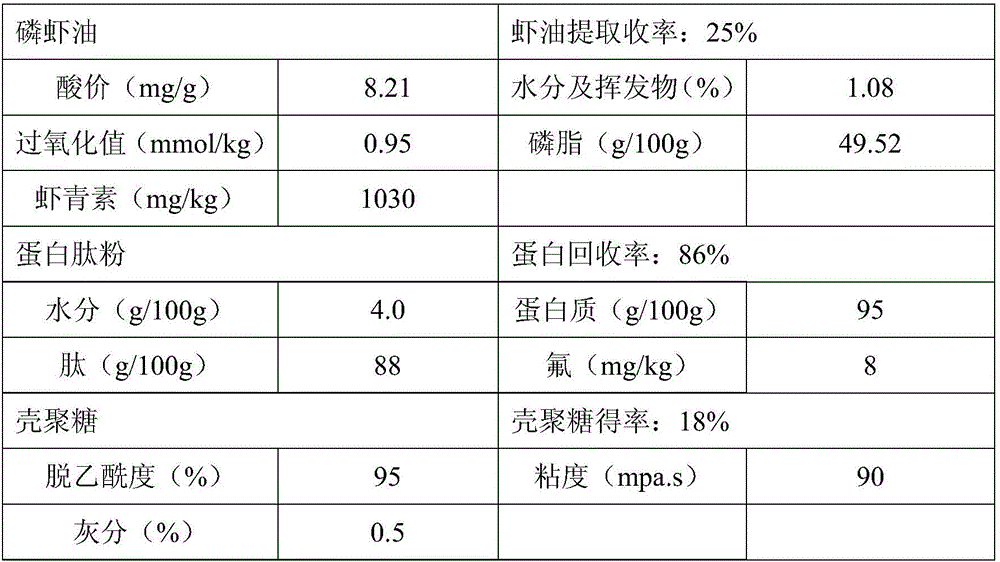

Embodiment 3

[0036] Antarctic krill powder fully utilizes the method of producing krill oil, protein peptide powder and chitosan, and the steps include:

[0037](1) Extraction of krill oil: add 100kg of shrimp powder to 1500L of absolute ethanol for extraction, temperature 45-65°C, stir and extract for 360min, press filter with nitrogen or carbon dioxide to obtain the residue and extract, add the residue to 225L of absolute alcohol for secondary Extraction, when the extract is evaporated under reduced pressure to an appropriate volume, centrifuged to remove impurities, evaporated and precipitated at low temperature and reduced pressure (45~65°C, -0.05~-0.10mPa) to obtain krill oil, and then add anhydrous alcohol to extract and layer, The upper layer is recovered as the solvent for the next extraction, the lower layer is desolvated and concentrated, and the extraction and stratification steps are repeated 4 times, and the organic solvent is recovered by the recovery tower for reuse;

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com