An ecological sponge brick made from waste rubber and plastic

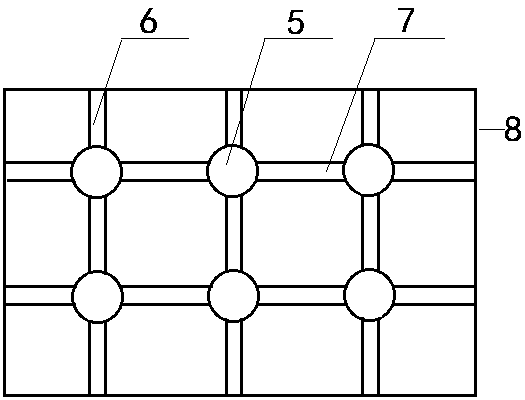

A technology of sponge bricks and waste rubber, which is applied in the field of preparation of municipal road permeable bricks. It can solve the problems of low cohesion or cohesion of bricks, difficulty in dispersing rainwater brick surfaces, and difficult cleaning of dirt. It achieves strong freeze-thaw resistance, Colorful urban landscape, effect of lightening the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

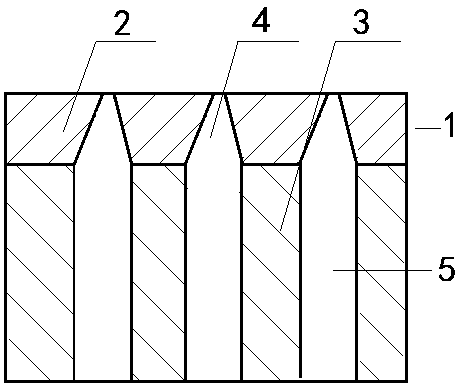

[0049] (3) Preparation of fabric and bottom material:

[0050] Step 6: Mix fine-grained waste rubber particles, fine-grained waste plastic particles, polytetrafluoroethylene sintered powder, and block copolymer evenly, then add the surface layer functional mixture prepared in step (4) and continue to stir evenly to obtain fabric.

[0051] Step 7: Coarse particle size waste rubber particles, coarse particle size waste plastic particles, waste glass, sandstone, polyacrylamide, and block copolymer are mixed evenly, and then the bottom functional mixture prepared in step (5) is added to continue stirring evenly. Get the base.

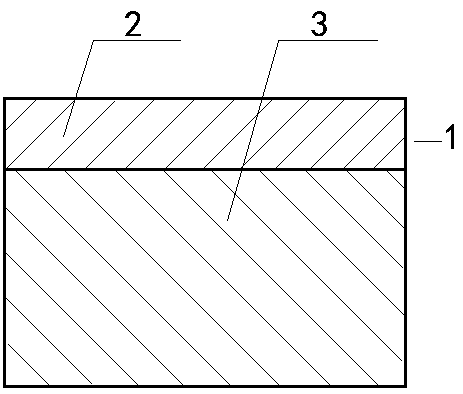

[0052] (4) Ecological sponge brick forming process:

[0053] Step 8: The eco-sponge brick forming mold has a vibration mechanism. Apply a heat-resistant mold release agent on the bottom metal plate of the mold and the inner wall of the mold frame. Put the fabric prepared in step (6) into the mold and vibrate evenly to form an ecological Sponge brick surf...

Embodiment 1

[0060]In this embodiment, waste and old natural rubber, waste and old neoprene rubber, waste and old nitrile rubber, and waste and old polyethylene, waste and old polypropylene, waste and old polyester, waste and old polystyrene, etc. are first sorted out. The waste rubber is cleaned, dehydrated and dried, and then pulverized by a pulverizer, or washed, dehydrated and dried after pulverization to form waste plastics and waste rubber pulverized materials, and the pulverized materials are sieved and selected as The particle size is about 1-3mm of fine-grained waste plastic particles and 3-5mm of coarse-grained waste rubber particles. At the same time, the waste glass is cleaned, dehydrated and dried, and then crushed into waste glass particles with a particle diameter of about 0.5-2mm by a pulverizer for standby.

[0061] In the present embodiment, the surface layer is compounded according to the following components and parts by weight: 20 parts of fine-grained waste rubber par...

Embodiment 2

[0074] In this embodiment, waste and old ethylene propylene rubber, waste and old silicone rubber, waste and old fluororubber, and waste and old polyethylene, waste and old polypropylene, waste and old polyester, waste and old polyvinyl chloride, etc. are first sorted out. The method and steps of 1 wash, dehydrate and dry waste rubber, waste plastic and waste glass, and select waste plastic particles with fine particle size, waste rubber particles with coarse particle size and waste glass particles through sieving.

[0075] In this embodiment, the surface layer is compounded according to the following components and parts by weight: 40 parts of fine-grained waste rubber particles, 40 parts of fine-grained waste plastic particles, 15 parts of nano-titanium dioxide, 10 parts of rare earth, 30 parts of calcium carbonate , 30 parts of bentonite, 12 parts of activated alumina, 25 parts of polytetrafluoroethylene sintered powder, 10 parts of block copolymer, 1.5 parts of calcium lign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com