Method for preparing farmland chemical fertilizer sustained-release agent and potash fertilizer by using biomass incineration ash

A technology of incineration ash and slow-release agent, which is applied in the preparation of alkali metal nitrate, nitrogen fertilizer, application, etc., can solve the problems of deteriorating air quality, formation of dust, waste, etc., to reduce the amount of extraction agent added, prevent redeposition, The Effect of Adding Amount of Water-saving Extractant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

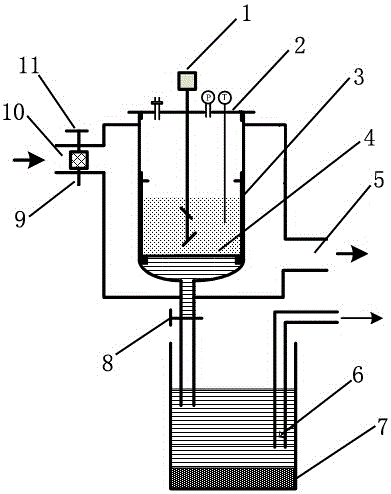

Embodiment 1

[0020] Embodiment one: get 20kg of biomass ash and place it on the ash rack 4, then put it into the reactor 3 stably, the inner wall of the reactor is made of Hastelloy, inject the configured 18kg dilute nitric acid solution (concentration is 25%), close Reactor cover 2, check the seal; open the reactor agitator 1; connect the bypass flue, use the waste heat of the flue gas to heat the reactor; observe the temperature and pressure in the reactor and the temperature change of the flue, and control the internal temperature of the reactor through the flue damper. Temperature, keep at a temperature of 180°C and a pressure of 1.6MPa for 12 minutes; after the holding time is completed, quickly open the discharge valve 8 at the bottom of the reactor, and the high-temperature solution quickly enters the cooling crystallization tank 7, which is filled with KNO at room temperature 3 The saturated solution is used as a cooling liquid, and after cooling, the KNO-rich 3 Coarse crystalline ...

Embodiment 2

[0021] Embodiment two: get 20kg biomass ash and be placed on the ash frame 4, put into reactor 3 steadily then, the inner wall of reactor is all made of Hastelloy alloy, injects the 20kg dilute nitric acid solution (concentration is 30%) of configuration, closes Reactor cover 2, check the seal; open the reactor agitator 1; connect the bypass flue, use the waste heat of the flue gas to heat the reactor; observe the temperature and pressure in the reactor and the temperature change of the flue, and control the internal temperature of the reactor through the flue damper. Temperature, at a temperature of 200°C and a pressure of 1.6MPa for 11 minutes; after the holding time is completed, quickly open the discharge valve 8 at the bottom of the reactor, and the high-temperature solution quickly enters the cooling crystallization tank 7, which is filled with KNO at room temperature 3 The saturated solution is used as a cooling liquid, and after cooling, the KNO-rich 3 Coarse crystalli...

Embodiment 3

[0022] Embodiment three: get 20kg biomass ash and be placed on the ash frame 4, put into reactor 3 stably then, the inner wall of reactor is all made of Hastelloy alloy, injects the 22kg dilute nitric acid solution (concentration is 40%) of configuration, closes Reactor cover 2, check the seal; open the reactor agitator 1; connect the bypass flue, use the waste heat of the flue gas to heat the reactor; observe the temperature and pressure in the reactor and the temperature change of the flue, and control the internal temperature of the reactor through the flue damper. Temperature, at a temperature of 220°C and a pressure of 1.5MPa for 10 minutes; after the holding time is completed, quickly open the discharge valve 8 at the bottom of the reactor, and the high-temperature solution quickly enters the cooling crystallization tank 7, which is filled with KNO at room temperature 3 The saturated solution is used as a cooling liquid, and after cooling, the KNO-rich 3 Coarse crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com