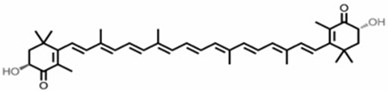

Method for promoting high yield of astaxanthin from phaffia rhodozyma

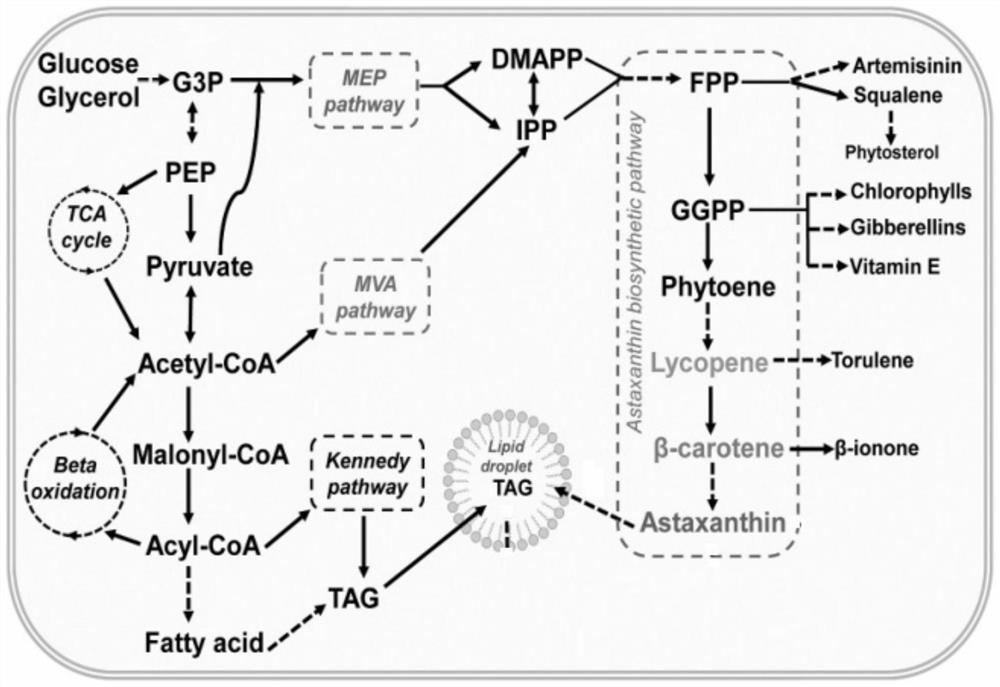

A Phaffia yeast and astaxanthin technology, which is applied in the field of TiO2/Al2O3 promoting the high production of astaxanthin by Phaffia yeast, can solve the problems of inefficient delivery of micron-sized titanium dioxide, low solubility, and low astaxanthin content, and achieves an increase in the Effects of Astaxanthin Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

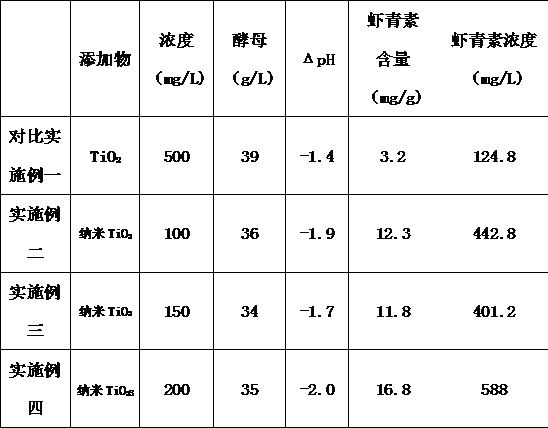

[0031] The fermentation method of the present invention can be applied to batch fermentation occasions, and can also be applied to continuous fermentation occasions. In this example, the production of astaxanthin by batch fermentation of Phaffia yeast in a 5L fermenter is taken as an example.

[0032] First, weigh 200mg of nano-titanium dioxide (Aladdin, CAS 13463 / 67 / 7, SKU# T104936), the solid particle size of the titanium dioxide is 60 nm; in addition, prepare 10mL of nano-alumina aqueous dispersion (Aladdin, CAS1344 / 28 / 1, SKU# A119404), the aqueous dispersion contains 20wt% nano-alumina particles with a particle size of 5-10 nanometers; mix 200mg of nano-titanium dioxide into 10mL of nano-alumina aqueous dispersion, stir Evenly, 10mL of nano-TiO containing 200mg of nano-titanium dioxide was prepared 2 / Al 2 o 3 Mother liquor; (due to the very small amount of 200mg, the volume will hardly increase after adding 10ml of nano-alumina aqueous dispersion, so the prepared nano...

Embodiment 3

[0040] The fermentation method of the present invention can be applied to batch fermentation occasions, and can also be applied to continuous fermentation occasions. In this example, the production of astaxanthin by batch fermentation of Phaffia yeast in a 5L fermenter is taken as an example.

[0041] First, weigh 400mg of nano-titanium dioxide (Aladdin, CAS 13463 / 67 / 7, SKU# T104936), the solid particle size of the titanium dioxide is 60 nm; in addition, prepare 10mL of nano-alumina aqueous dispersion (Aladdin, CAS 1344 / 28 / 1, SKU# A119404), the aqueous dispersion contains 20wt% nano-alumina particles with a particle size of 5-10 nanometers; mix 300mg of nano-titanium dioxide into 10mL of nano-alumina aqueous dispersion, Stir evenly to prepare 10mL containing 300mg nano-TiO 2 Nano TiO 2 / Al 2 o 3 Mother liquor; (because the amount of 300mg is very small, after adding 10ml of nano-alumina aqueous dispersion, the volume will hardly increase, so the prepared nano-TiO 2 / Al ...

Embodiment 4

[0049] The fermentation method of the present invention can be applied to batch fermentation occasions, and can also be applied to continuous fermentation occasions. In this example, the production of astaxanthin by batch fermentation of Phaffia yeast in a 5L fermenter is taken as an example.

[0050] First, weigh 400mg of nano-titanium dioxide (Aladdin, CAS 13463 / 67 / 7, SKU# T104936), the solid particle size of the titanium dioxide is 60 nm; in addition, prepare 10mL of nano-alumina aqueous dispersion (Aladdin, CAS 1344 / 28 / 1, SKU# A119404), the aqueous dispersion contains 20wt% nano-alumina particles with a particle size of 5-10 nanometers; mix 400mg of nano-titanium dioxide into 10mL of nano-alumina aqueous dispersion, Stir evenly to prepare 10ml of nano-TiO containing 400mg of nano-titanium dioxide 2 / Al 2 o 3 Mother liquor; (due to the very small amount of 400mg, adding 10ml of nano-alumina aqueous dispersion will hardly increase the volume, so the prepared nano-TiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com