Low-frequency high-energy ultrasonic-coupled fluidized beet-exudating method and device

A high-energy ultrasonic and fluidized technology, applied in the chemical/physical/physical-chemical process of extracting sugar from sugar beet and applying energy, etc., can solve the problems of affecting the shape of waste shredded cabbage, no technical solutions, and high energy consumption of dry meal , to shorten the exudation time, reduce the sugar loss, and improve the separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

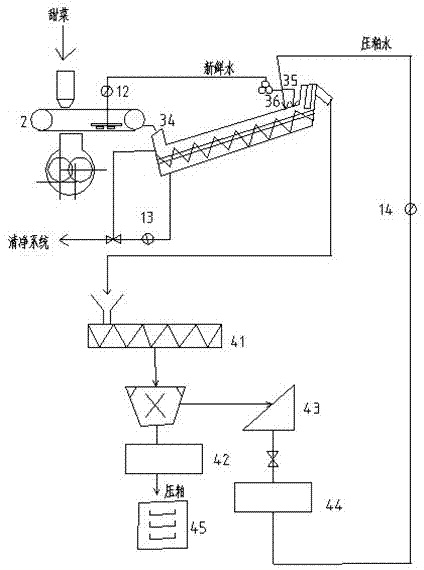

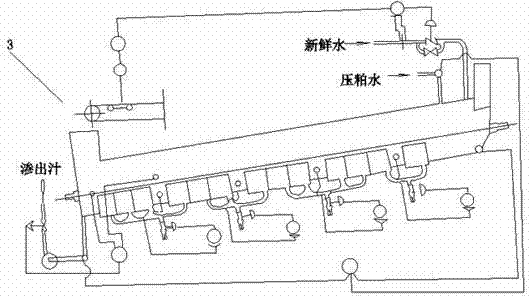

[0037] like figure 1As shown, a oozing device provides a oozing device, including a pretreatment system and a leaching device 3 connected by a belt conveyor, and the high-end output port of the leaching device 3 is facing the input of the waste meal water recovery system The outlet of the low end of the exudator is connected with the input port of the exudate juice treatment system; the low end of the exudator is provided with a vegetable feeding bucket 34, and the high end of the exudator is respectively provided with a water inlet 36 and a water inlet 35.

[0038] The pretreatment system includes a shredder 11, a first blancher 12 and a courgette pump (not shown in the figure) which are sequentially connected by a conveyor belt of a belt conveyor.

[0039] The waste meal water recycling system includes a screw conveyor 41, a press machine 42, a curved screen 43, a meal pressing water tank 44 and a third scalding device 14 which are connected successively by the conveyor belt...

Embodiment 2

[0047] This embodiment is except following feature, and other is all identical with embodiment 1:

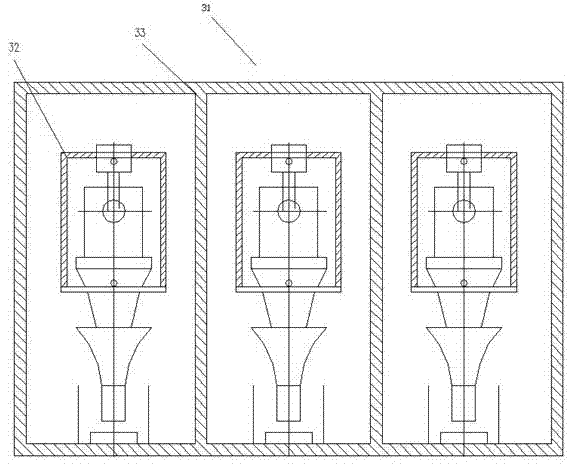

[0048] Four groups of plate-type submerged ultrasonic extraction devices are continuously installed in the middle of the tank bottom (third and fourth sections) in the Dds double-helix chute continuous exfiltration device, and the spacing is equal and evenly distributed to achieve the effect of enhancing the balance of exudation efficiency.

[0049] In this embodiment, the first section and the second section at the lower end of the Dds double-helix chute continuous oozer are heated with exhaust steam, and the air intake mode is air intake from both sides; The third and fourth sections are heated with evaporating three-effect gas. Heat the vegetable-water mixture to the required temperature (about 70°C in the first section of the Dds double-helix chute-type continuous oozer, and about 50°C in the end section of the Dds double-helix chute-type continuous oozer), ultrasonic freque...

Embodiment 3

[0051] This embodiment is except following feature, and other is all identical with embodiment 1:

[0052] Five groups of plate-type submerged ultrasonic extraction devices are continuously installed in the middle of the tank bottom (third and fourth sections) of the Dds double-helix chute continuous exfiltration device, and the spacing is equal and evenly distributed to achieve the effect of enhancing the balance of exudation efficiency.

[0053] In this embodiment, the first section and the second section at the lower end of the Dds double-helix chute continuous oozer are heated with exhaust steam, and the air intake mode is air intake from both sides; The third and fourth sections are heated with evaporating three-effect gas. Heat the vegetable-water mixture to the required temperature (about 70°C in the first section of the Dds double-helix chute-type continuous oozer, and about 50°C in the end section of the Dds double-helix chute-type continuous oozer), ultrasonic freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com