Method for preparing polymer/graphite nanometer composite material by utilizing ultrasonic dispersion technology

A nanocomposite material and polymer technology, applied in the field of polymer/modified graphite nanocomposite materials and their preparation, can solve problems such as uneven dispersion of graphite and reduced mechanical properties of materials, and achieve simplified preparation procedures, superior performance, and solutions the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

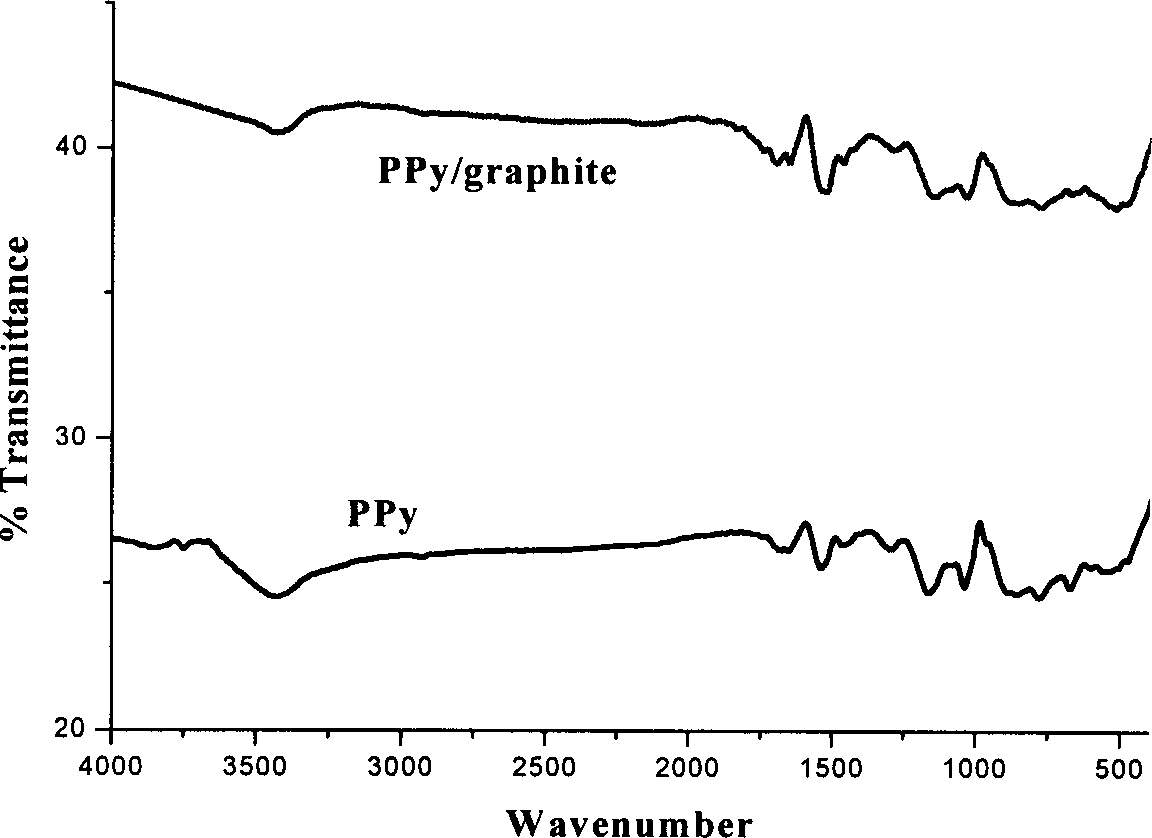

[0036] Embodiment 1, the preparation of polypyrrole / graphite flake nanocomposite material:

[0037] ① Dissolve expanded graphite in ethanol, ultrasonically pulverize for 10 hours under the condition of ultrasonic frequency of 80 Hz and temperature of 40 °C, filter and wash to obtain graphite nano-chips;

[0038] ② Dissolve the pyrrole monomer in ethanol, then add sodium lauryl sulfate 5 times the mass of the pyrrole monomer and graphite nano-chips 0.08 times the mass of the pyrrole monomer, stir evenly, and ultrasonically treat at room temperature for 10 minutes;

[0039] ③ Add ferric chloride hexahydrate 8 times the mass of pyrrole monomer and 0.5 times the hydrochloric acid dopant, make the mixed solution polymerize for 4 hours under the condition of -5 ~ 5 ℃ ice-water bath, then transfer to room temperature and stir for 12 hours , the product was filtered, the precipitate was repeatedly washed with secondary water and absolute ethanol, and the obtained solid was vacuum-drie...

Embodiment 2

[0040] Embodiment 2, the preparation of polypyrrole / graphite flake nanocomposite material:

[0041] ①Dissolve expanded graphite in chloroform, ultrasonically pulverize for 12 hours under the condition of ultrasonic frequency of 90Hz and temperature of 35°C, filter and wash to obtain graphite nano-chips;

[0042] ②Dissolve the pyrrole monomer in chloroform, then add sodium stearate with 4 times the weight of the pyrrole monomer and graphite nanoplatelets with 0.1 times the weight of the pyrrole monomer, stir evenly, and ultrasonically treat at room temperature for 20 minutes;

[0043] ③Add iron trichloride hexahydrate 9 times the mass of pyrrole monomer and 1.5 times the methanesulfonic acid dopant, make the mixed solution polymerize for 3 hours under the condition of ice-water bath at -5~5℃, then transfer to room temperature and stir After 15 hours, the product was filtered, the precipitate was repeatedly washed with secondary water and absolute ethanol, and the obtained solid...

Embodiment 3

[0044] Embodiment 3, the preparation of polypyrrole / graphite flake nanocomposite material:

[0045] ①Dissolve expanded graphite in ethanol, ultrasonically pulverize it for 12 hours under the condition of ultrasonic frequency of 100Hz and temperature of 35°C, filter and wash to obtain graphite nano-chips;

[0046] ②Dissolve the pyrrole monomer in ethanol, then add polyethylene coupling agent with 2 times the volume of the pyrrole monomer and graphite nano-chips with 0.15 times the mass of the pyrrole monomer, stir evenly, and ultrasonically treat at room temperature for 30 minutes;

[0047] ③ Add iron trichloride hexahydrate 10 times the mass of pyrrole monomer and 0.8 times the dopant of p-toluenesulfonic acid, and polymerize the mixed solution for 2 hours in an ice-water bath at -5 to 5°C, and then turn it to room temperature After stirring for 24 hours, the product was filtered, and the precipitate was repeatedly washed with secondary water and absolute ethanol, and the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com