Ammonium polyphosphate water soluble fertilizer and preparation method thereof

A water-soluble fertilizer and ammonium polyphosphate technology, which is applied in the direction of phosphate, phosphorus oxyacid, fertilizer mixture, etc., can solve the problem that ammonium polyphosphate is not suitable for agricultural water-soluble fertilizers, is not suitable, and ammonium polyphosphate is low Water solubility and other issues, to achieve the effect of low production cost, high effective content and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

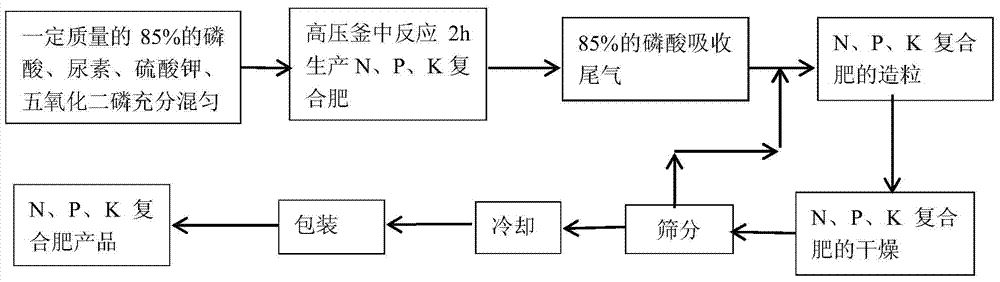

Method used

Image

Examples

Embodiment 1

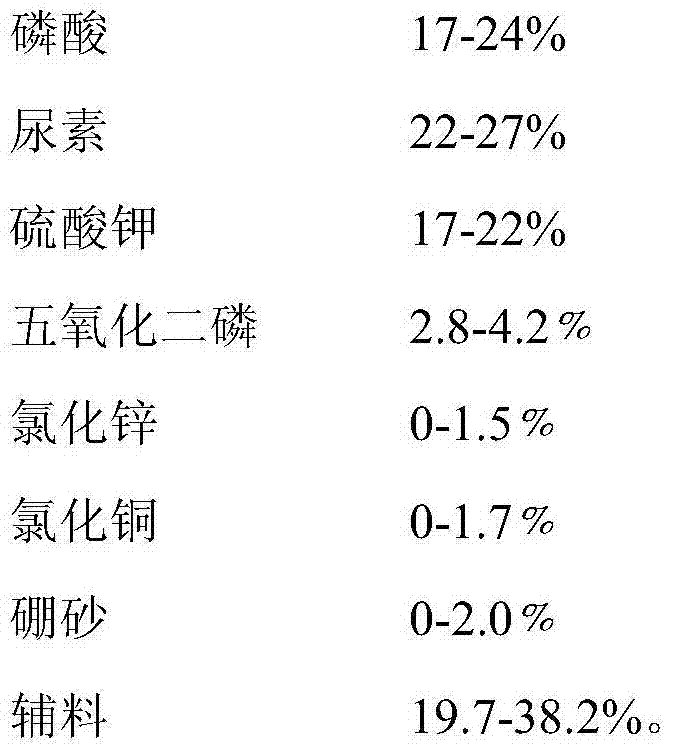

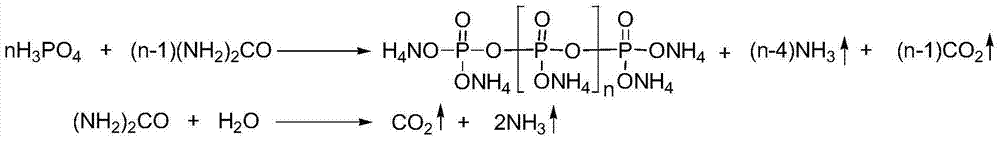

[0030] Add 18kg of 85% phosphoric acid, 22kg of urea, 18.6kg of potassium sulfate and 29kg of auxiliary materials in a 50L autoclave, mix and dissolve in the kettle, then add 3.6kg of phosphorus pentoxide and stir evenly. Under stirring, the temperature of the reactor was raised to 180°C, and the reaction was carried out for 30 minutes, and then the temperature was raised to 200°C for 1.5 hours. During the reaction process, the partial pressure of ammonia is controlled at 3±0.2MPa. After the reaction is completed, the temperature in the reactor is gradually lowered, and at the same time, the ammonia gas produced by the reaction is absorbed with dilute phosphoric acid solution, and the ammonium polyphosphate-potassium sulfate water-soluble fertilizer can be obtained. . The product index is shown in Table 1.

Embodiment 2

[0032] Add 19kg of 80% phosphoric acid, 24.3kg of urea, 18kg of potassium sulfate and 32kg of auxiliary materials in sequence in a 50L high-pressure reactor, then add 3.8kg of phosphorus pentoxide and stir evenly. Under stirring, the temperature of the reactor was raised to 185°C, and the reaction was carried out for 40 minutes, and then the temperature was raised to 205°C for 2 hours. During the reaction process, the partial pressure of ammonia is controlled at 3±0.2MPa. After the reaction is completed, the temperature in the reactor is gradually lowered, and at the same time, the ammonia gas produced by the reaction is absorbed with dilute phosphoric acid solution, and the ammonium polyphosphate-potassium sulfate water-soluble fertilizer can be obtained. . The product index is shown in Table 1.

Embodiment 3

[0034] Add 19.2kg of 82% phosphoric acid, 25kg of urea, 18.7kg of potassium sulfate and 36kg of auxiliary materials in sequence in a 50L high-pressure reactor, then add 3.9kg of phosphorus pentoxide and stir evenly. Under stirring, the temperature of the reactor was raised to 182°C, and the reaction was carried out for 45 minutes, and then the temperature was raised to 203°C for 1.8 hours. During the reaction process, the partial pressure of ammonia is controlled at 3±0.2MPa. After the reaction is completed, the temperature in the reactor is gradually lowered, and at the same time, the ammonia gas produced by the reaction is absorbed with dilute phosphoric acid solution, and the ammonium polyphosphate-potassium sulfate water-soluble fertilizer can be obtained. . The product index is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com