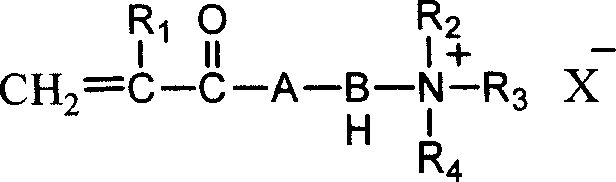

Method of synthesizing cation polyacrylamide water-in-water emulsion

A technology of polyacrylamide and synthesis method, applied in the field of synthesis of water-soluble polymers, can solve problems such as poor fluidity of polymer emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 85g deionized water, 57g ammonium sulfate, 22g acrylamide, 11g methacryloxyethyltrimethylammonium chloride (concentration 80%) solution, 11g acryloyloxyethyltrimethylammonium chloride (concentration is 80%) solution, 45g stabilizer A, 0.02g EDTA; Constant temperature 35 ℃, stirring 800 rpm, nitrogen to remove the oxygen. After passing nitrogen for about 15 minutes, 0.02 ml of 1 wt % V044 solution was added. After 2 hours, the polymerization started, and the viscosity of the system continued to increase within 30 minutes. After 2 hours of the polymerization, the system gradually changed from transparent to milky white, and the viscosity gradually decreased. At this point 0.02 ml of 1 wt% V044 solution was added. 0.04ml of 1wt% V044 solution was added in 4 hours, 0.08ml of 1wt% V044 solution was added in 8 hours, and the reaction continued for 24 hours. After adding 2 g of ammonium sulfate for viscosity reduction, the reaction product was taken out to obtain a milk...

Embodiment 2

[0023] Add 85g deionized water, 57g ammonium sulfate, 22g acrylamide, 5g methacryloxyethyltrimethylammonium chloride (concentration 80%) solution, 17g acryloyloxyethyltrimethylammonium chloride (concentration is 80%) solution, 45g stabilizer A, 0.02g EDTA; Constant temperature 35 ℃, stirring 800 rev / min, nitrogen to remove in the system oxygen. After passing nitrogen for about 15 minutes, 0.02 ml of 1 wt % V044 solution was added. After 2 hours, the polymerization started, and the viscosity of the system continued to increase within 30 minutes. Within 3 hours of the polymerization, the system gradually changed from transparent to milky white, and the viscosity gradually decreased. At this point, 0.02ml of 1wt% V044 solution was added, 0.04ml of 1wt% V044 solution was added in 4 hours, 0.08ml of 1wt% V044 solution was added in 8 hours, and the reaction continued for 24 hours. After adding 2g of ammonium sulfate to lower the viscosity, take it out to obtain a milky white dispe...

Embodiment 3

[0025]Add 85g of deionized water, 57g of ammonium sulfate, 22g of acrylamide, 2g of methacryloxyethyltrimethylammonium chloride (concentration 80%) solution, 20g acryloyloxyethyltrimethylammonium chloride (concentration is 80%) solution, 45g stabilizer A, 0.02g EDTA; Constant temperature 35 ℃, stir 800 rpm, pass nitrogen to remove the oxygen. After passing nitrogen for about 15 minutes, 0.02 ml of 1 wt % V044 solution was added. After 2 hours, the polymerization started, and the viscosity of the system continued to increase within 30 minutes. Within 3.5 hours of the polymerization, the system gradually changed from transparent to milky white, and the viscosity gradually decreased. At this point, 0.02ml of 1wt% V044 solution was added, 0.04ml of 1wt% V044 solution was added in 4 hours, 0.08ml of 1wt% V044 solution was added in 8 hours, and the reaction continued for 24 hours. After adding 2g of ammonium sulfate to lower the viscosity, take it out to obtain a milky white dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com