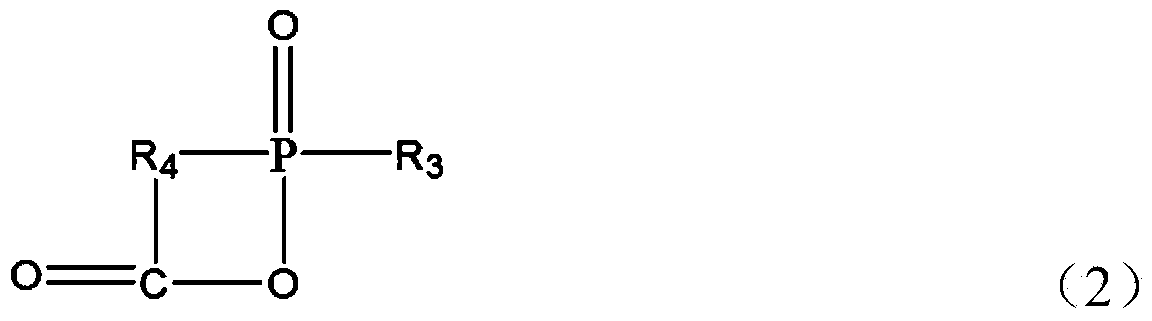

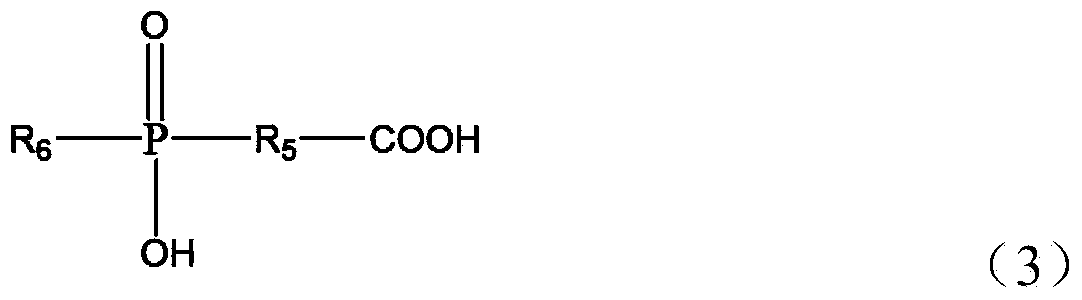

Preparation method of cationic dyeable flame-retardant polyester resin

A technology of cationic dyes and flame-retardant polyesters, which is applied in the field of preparation of organic polymer compounds, and can solve problems such as high addition of flame retardants, increased dyeing capacity, poor flame retardancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Take 1.91kg of hydroxyethylphenyl hypophosphorous acid, 10kg of ethylene glycol and 0.2g of composite catalyst (antimony acetate: zinc acetate = 3:1) and place them in reactor A, stir evenly and heat up to 175°C, under the condition of pressure 60kPa , and discharged after 4 hours of esterification to obtain a flame retardant esterification liquid.

[0073] Take 1.2kg of dimethyl isophthalate-5-sodium sulfonate, 4.8kg of ethylene glycol and 0.06g of composite catalyst (antimony acetate:magnesium acetate=2:1), put them in reaction kettle B, stir evenly and heat up to At 165°C, under the condition of a pressure of 55kPa, the material was discharged after the transesterification reaction for 4 hours to obtain a bishydroxyethyl isophthalate-5-sodium sulfonate solution.

[0074] Take 40kg of terephthalic acid and 20.9kg of ethylene glycol and place them in reactor C, stir evenly, raise the temperature to 248°C, and carry out the esterification reaction for 3 hours. After the...

Embodiment 2

[0076] Take 2.34kg of hydroxyethylphenyl hypophosphorous acid, 10kg of ethylene glycol and 0.23g of composite catalyst (calcium acetate: manganese acetate = 2:1) and place them in reactor A, stir evenly and heat up to 155°C, under the condition of pressure 65kPa , and discharged after 4.5 hours of esterification to obtain a flame retardant esterification solution.

[0077] Take 0.4kg of dimethyl isophthalate-5-sodium sulfonate, 1.2kg of ethylene glycol and 0.08g of composite catalyst (calcium acetate: antimony acetate = 1:1), put them in reaction kettle B, stir evenly and heat up to Under the condition of 175°C and a pressure of 50kPa, the material was discharged after the transesterification reaction for 3 hours to obtain a bishydroxyethyl isophthalate-5-sodium sulfonate solution.

[0078] Take 40kg of terephthalic acid and 19.0kg of ethylene glycol and place them in reactor C, stir, raise the temperature to 255°C, and carry out esterification reaction for 3 hours. After the ...

Embodiment 3

[0080] Take 2.94kg of hydroxyethylphenyl hypophosphorous acid, 10kg of ethylene glycol and 0.25g of composite catalyst (manganese acetate: cobalt acetate = 3:1) in reactor A, stir evenly and heat up to 160°C, under the condition of pressure 45kPa , and discharged after 3 hours of esterification to obtain a flame retardant esterification liquid.

[0081] Take 0.20kg of isophthalic acid-5-sodium sulfonate, 3.6kg of ethylene glycol and 0.07g of composite catalyst (zinc acetate: cobalt acetate = 1:1), put them in reaction kettle B, stir evenly and heat up to 160°C, Under the condition of a pressure of 40kPa, after 3.5 hours of the transesterification reaction, the material was discharged to obtain a bishydroxyethyl isophthalate-5-sodium sulfonate solution.

[0082] Take 40kg of terephthalic acid and 18.5kg of ethylene glycol and place them in reactor C, stir, raise the temperature to 250°C, and carry out the esterification reaction for 2.5 hours. After the esterification reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com