Method for preparing octacosanol and triacontanol from rice bran wax

A technology of octacosanol and triacontanol, applied in chemical instruments and methods, preparation of oxygen-containing compounds, preparation of organic compounds, etc., can solve problems such as difficult hydrolysis, long reaction time, harsh reaction conditions, etc., and achieve The effect of short reaction time, low production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

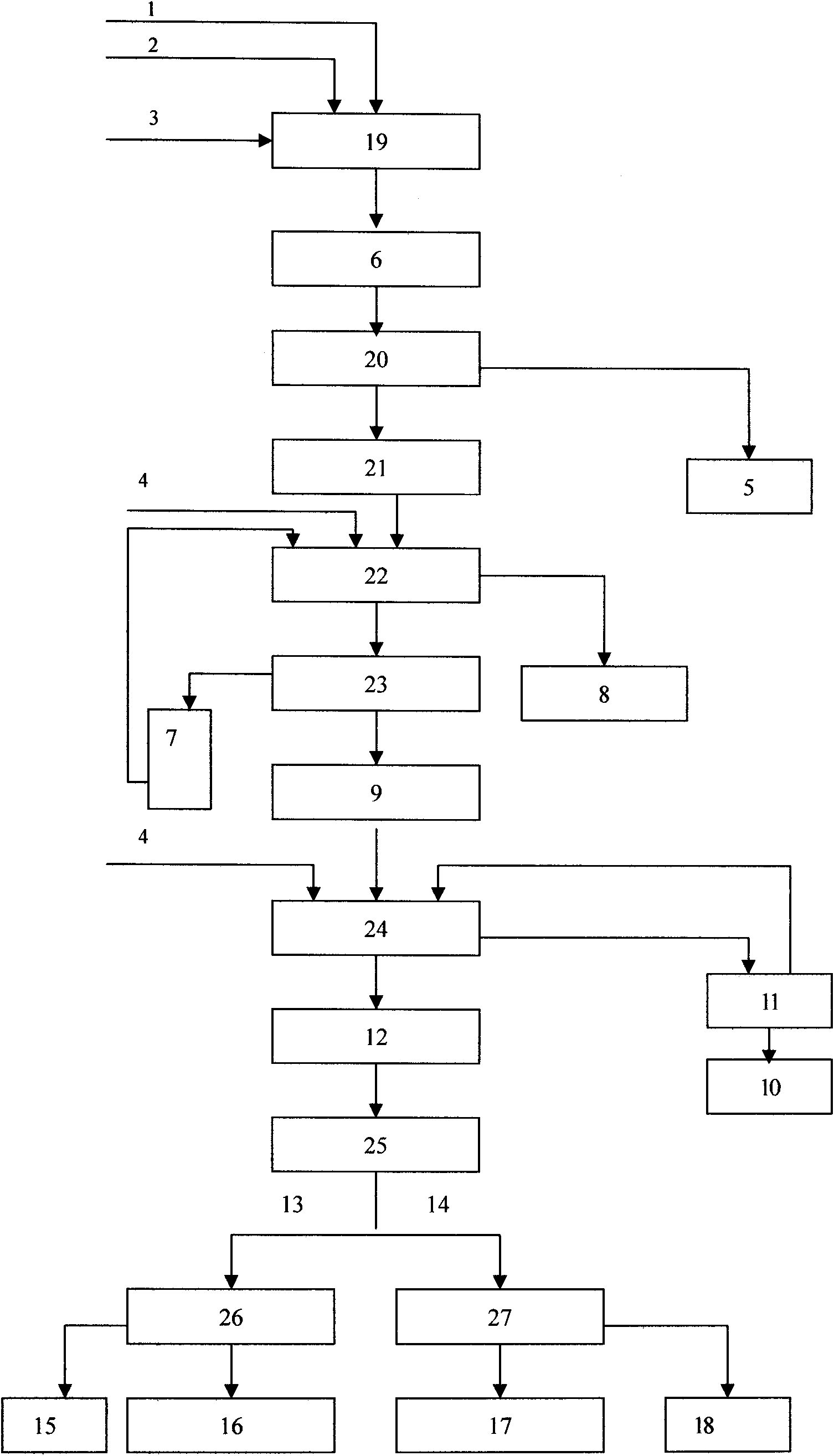

[0013] 1. Add 1200g of rice bran hair wax, 232g of calcium hydroxide, and 3800ml of water into a 1000ml reactor, and use P=150 w f=150KHz ultrasonic wave 19, heated to 90-95°C, 0.05MPa, reacted for 2 hours.

[0014] 2. Cool down to room temperature, the product in the reaction system forms a hard lump, separate it and separate it from the mother liquor for 20, discard the reaction mother liquor 5, and wash the lump product with clean water for many times until the pH value is medium sex.

[0015] 3. Put the resultant 7 in an oven at 105°C and dry for 21 to constant weight to obtain 7223g of mixed alcohol and fatty acid calcium and pulverize it into powder.

[0016] 4. Transfer 7223g of mixed alcohol and fatty acid calcium into another 1000ml reactor, and carry out circular extraction 22 with 700ml ethanol at t=95°C. After cooling the raffinate, distill off the solvent to obtain fatty acid calcium 8.

[0017] 5. After the extraction mother liquors 6 are combined, crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com