Higher aliphatic alcohol emulsion antifoaming agent

A high-grade fatty alcohol and defoamer technology, applied in defoamer, non-polymer organic compound addition, textile and papermaking, etc., can solve the problem of insufficient carbon chain length of natural fatty alcohol, high price of synthetic fatty alcohol, defoaming inhibition problems such as poor foaming ability, to achieve the effect of increasing added value, improving performance and stability, and enriching sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

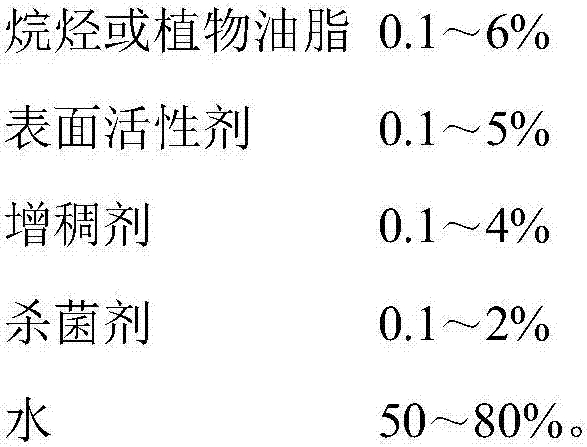

Method used

Image

Examples

Embodiment 1

[0085] High-grade fatty alcohol emulsion defoamer 1, each component by mass percentage is: refined rice bran wax 20%, 52# paraffin wax 4%, 32# mineral oil 4%, sodium dodecyl diphenyl ether disulfonate 1.2%, Acrylic acid thickener 1.6%, glutaraldehyde 0.2%, water 69% are prepared, and the emulsion viscosity of the newly prepared product is 522mPa.s.

Embodiment 2

[0087] Higher fatty alcohol emulsion defoamer 2, each component by mass percentage is: refined rice bran wax 18%, 52# paraffin wax 5%, palm oil 5%, isomerized tridecyl alcohol polyoxyethylene ether (12EO) 1.2%, acrylic acid Thickener 1.6%, isothiazolinone 0.2%, water 69%, the emulsion viscosity of the newly prepared product is 482mPa.s.

Embodiment 3

[0089] Higher fatty alcohol emulsion defoamer 3, each component by mass percentage is: refined rice bran wax 20%, 70# microcrystalline wax 4%, palm oil 4%, sodium dodecyl diphenyl ether disulfonate 1.2%, Acrylic acid thickener 1.6%, glutaraldehyde 0.2%, water 69% are prepared, and the emulsion viscosity of the newly prepared product is 620mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com