Production method of refined rice bran wax

A production method and technology of rice bran wax, which is applied in the production field of refined rice bran wax, can solve the problems of unreliable refining and purification, low production efficiency, and environmental pollution, and achieve the effect of novel and unique method, high production efficiency, and development of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

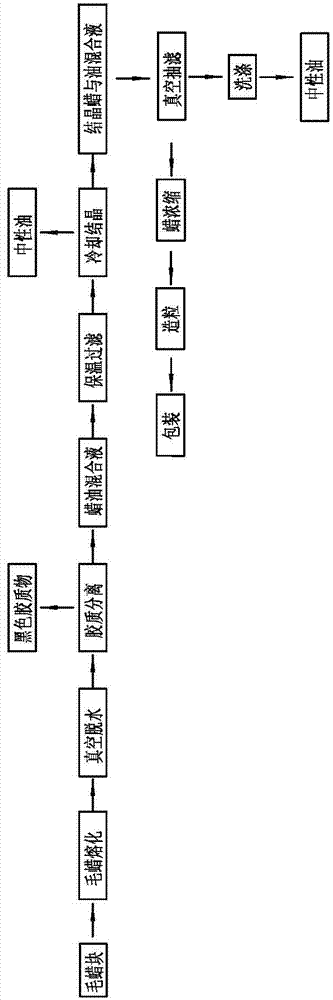

Method used

Image

Examples

Embodiment 1

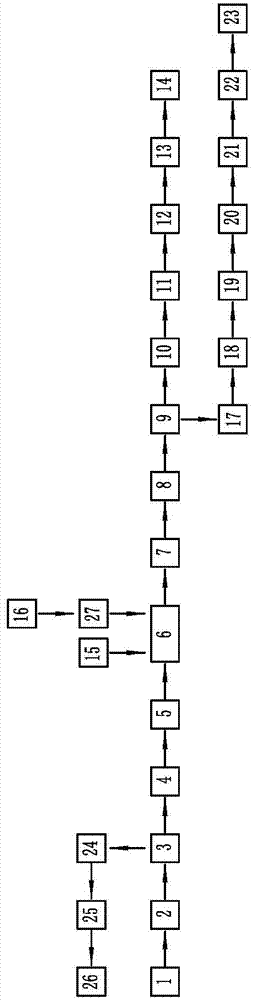

[0019] In the specific implementation of the present invention, a kind of production method of refined rice bran wax comprises the following steps:

[0020] 1) Melting the rough rice bran wax: put the rough rice bran wax block into the melting tank 1, heat up to 85°C, melt the rough rice bran wax block, and form a rough rice bran wax liquid;

[0021] 2) Vacuum dehydration: the crude rice bran wax liquid enters the vacuum drying pot 3 through the molten salt pump 2, heats up to 108°C, vacuumizes and stirs to remove the moisture in the crude rice bran wax liquid;

[0022] 3) Separation of colloids: the wax liquid of crude rice bran after water removal is pumped into the high-level metering tank 5 through the first oil pump 4, and then into the extraction tank 6 through the high-level metering tank 5, adding solvent and adsorbent, stirring for 2 hours, and temperature control Reflux extraction at 77°C, settling for 2 hours to separate layers, the colloid in the lower layer is dis...

Embodiment 2

[0029] In the specific implementation of the present invention, a kind of production method of refined rice bran wax comprises the following steps:

[0030] 1) Melting the rough rice bran wax: put the rough rice bran wax block into the melting tank 1, heat up to 90°C, melt the rough rice bran wax block, and form a rough rice bran wax liquid;

[0031] 2) Vacuum dehydration: the crude rice bran wax liquid enters the vacuum drying pot 3 through the molten salt pump 2, heats up to 110°C, vacuumizes and stirs to remove the moisture in the crude rice bran wax liquid;

[0032] 3) Separation of colloids: the wax liquid of crude rice bran after water removal is pumped into the high-level metering tank 5 through the first oil pump 4, and then into the extraction tank 6 through the high-level metering tank 5, adding solvent and adsorbent, stirring for 2 hours, and temperature control Reflux extraction at 80°C, settling for 2 hours to separate layers, the colloid in the lower layer is dis...

Embodiment 3

[0039] In the specific implementation of the present invention, a kind of production method of refined rice bran wax comprises the following steps:

[0040] 1) Melting the rough rice bran wax: put the rough rice bran wax block into the melting tank 1, heat up to 95°C, melt the rough rice bran wax block, and form a rough rice bran wax liquid;

[0041] 2) Vacuum dehydration: the crude rice bran wax enters the vacuum drying pot 3 through the molten salt pump 2, heats up to 113°C, vacuumizes and stirs to remove the moisture in the crude rice bran wax;

[0042] 3) Separation of colloids: the wax liquid of crude rice bran after water removal is pumped into the high-level metering tank 5 through the first oil pump 4, and then into the extraction tank 6 through the high-level metering tank 5, adding solvent and adsorbent, stirring for 2 hours, and temperature control Reflux extraction at 83°C, settling for 2 hours to separate layers, the colloid in the lower layer is discharged from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com