Wood-plastic composite material for processing road signs and preparation method thereof

A technology for wood-plastic composite materials and road signs, applied in the field of wood-plastic composite materials, can solve problems such as affecting the normal use of road signs, requiring regular maintenance or replacement, blistering or peeling of reflective films, and increasing market competitiveness. , The effect of improving the safety of use and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

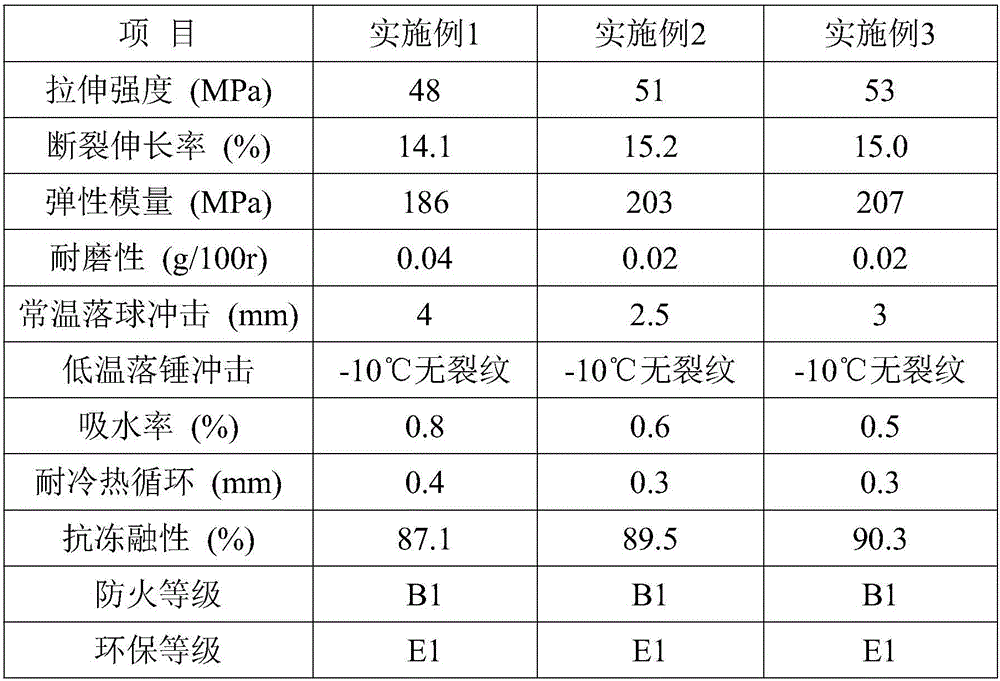

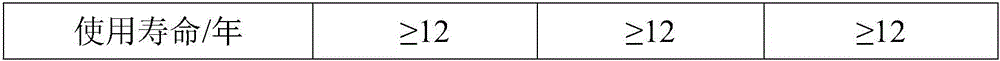

Embodiment 1

[0028] (1) Add 5 parts of polyvinyl alcohol resin and 4 parts of rubber powder to 25 parts of beverage bottle recycled plastic granules, heat to 120-125°C and mix for 15 minutes, then add 2 parts of pigment and 2 parts of nano rubber powder, and continue to keep warm Mix for 5min to obtain material I;

[0029] (2) Add 3 parts of polyethylene oxide, 2 parts of hydrogenated palm oil and 0.5 part of nano-alumina to 5 parts of chlorinated polyethylene, and heat to 125-130 ° C for 15 minutes to heat and mix to obtain material II;

[0030] (3) Add 5 parts of coco peat and 3 parts of activated clay to 20 parts of wood flour, fully mix them in an environment of 55-60°C and let them stand for 2 hours, then heat them to 100-105°C and keep them mixed until the water content is lower than 2%. Then use the ultrafine pulverizer to make powder to obtain material III;

[0031] (4) Add material II, 1 part of dodecyltrimethylammonium chloride, 0.5 part of trimellitic anhydride and 0.5 part of ...

Embodiment 2

[0034] (1) Add 5 parts of polyvinyl alcohol resin and 4 parts of rubber powder to 25 parts of beverage bottle recycled plastic granules, heat to 120-125°C and mix for 15 minutes, then add 2 parts of pigment and 2 parts of nano rubber powder, and continue to keep warm Mix for 5min to obtain material I;

[0035] (2) Add 5 parts of polyethylene oxide, 1 part of hydrogenated palm oil and 0.5 part of nano-alumina to 5 parts of chlorinated polyethylene, and heat to 125-130 ° C and mix for 15 minutes to obtain material II;

[0036] (3) Add 5 parts of coconut peat and 5 parts of activated clay to 20 parts of wood flour, fully mix them in an environment of 55-60°C and let them stand for 2 hours, then heat them to 100-105°C and keep them mixed until the water content is lower than 2%. Then use the ultrafine pulverizer to make powder to obtain material III;

[0037] (4) Add material II, 1 part of dodecyltrimethylammonium chloride, 0.5 part of trimellitic anhydride and 0.5 part of 2-imid...

Embodiment 3

[0041] (1) Add 8 parts of polyvinyl alcohol resin and 4 parts of rubber powder to 25 parts of beverage bottle recycled plastic granules, heat to 120-125°C and mix for 15 minutes, then add 3 parts of pigment and 2 parts of nano rubber powder, and continue to keep warm Mix for 5min to obtain material I;

[0042] (2) Add 5 parts of polyethylene oxide, 1 part of hydrogenated palm oil and 1 part of nano-alumina to 5 parts of chlorinated polyethylene, and heat to 125-130° C. and mix for 15 minutes to obtain material II;

[0043] (3) Add 5 parts of coco peat and 3 parts of activated clay to 20 parts of wood flour, fully mix them in an environment of 55-60°C and let them stand for 2 hours, then heat them to 100-105°C and keep them mixed until the water content is lower than 2%. Then use the superfine pulverizer to make powder to obtain material III;

[0044] (4) Add material II, 1 part of dodecyltrimethylammonium chloride, 0.5 part of trimellitic anhydride and 0.5 part of 2-imidazoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com