Method for preparing candle base oil by using vegetable oil

A vegetable oil and base oil technology, applied in the production of candles and fatty acids, can solve the problems of adding paraffin, and achieve the effect of reducing production and export costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Palm stearin with an iodine value of 35.96gI / 100g is obtained by fractionation of palm oil. Add 2% clay at 100°C for vacuum decolorization for 40 minutes and then enter the deodorization tower. Steam stripping at a deodorization temperature of 250°C for 4 hours can obtain candle base Add 3% monoglyceride (mass percentage, based on candle base oil, the same below) after the base oil is melted, add pigment or essence as needed, adjust the temperature to 75°C, and put the wax core Wet it with base material oil, place it in the middle of the mold, pour the model at a temperature of 20°C, and then cool it to shape.

Embodiment 2

[0044] Palm stearin with an iodine value of 22.34gI / 100g is obtained by fractionation of palm oil. Add 0.1% clay at 130°C for vacuum decolorization for 20 minutes, then enter the deodorization tower, and steam strip at a deodorization temperature of 230°C for 2 hours to obtain candle base Base oil, add 2% monoglyceride after melting the base oil, add pigment or essence as needed, adjust the temperature to 75°C, soak the wax core with base oil, place it in the middle of the mold, The mold is poured in an environment of 20°C, and then cooled for molding.

Embodiment 3

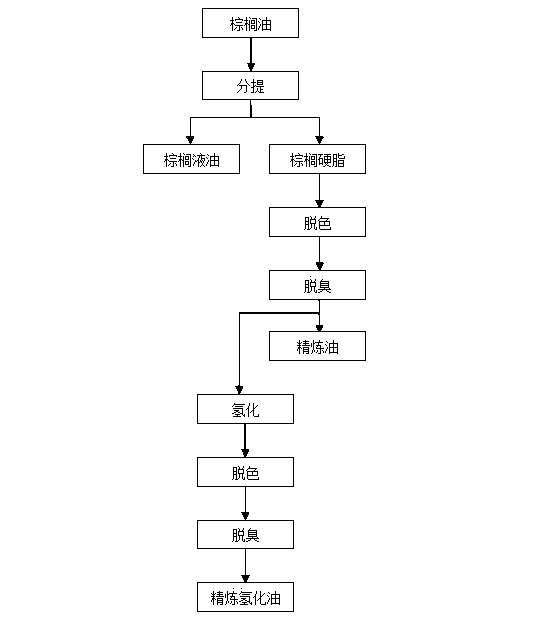

[0046] Use palm oil as raw material to obtain hydrogenated palm oil with an iodine value of 0.58gI / 100g through fractionation and hydrogenation treatment. Add 5% clay at 80°C for vacuum decolorization for 30 minutes and then enter the deodorization tower. Steam stripping at a deodorization temperature of 260°C for 3 hours can be Obtain candle base oil, add 1% monoglyceride after melting the base oil, add pigments or essences as needed, adjust the temperature to 80°C, soak the wax core with base oil, and place it in the middle of the mold , cast the model in an environment with a temperature of 20°C, and then cool and form it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com