A kind of method utilizing hydrogenated oil to prepare pentaerythritol stearate

A technology of pentaerythritol stearate and pentaerythritol, applied in chemical instruments and methods, preparation of organic compounds, carboxylate preparation, etc., can solve the problems of long saponification time, incomplete saponification, and difficult saponification of saponification reaction, and achieve shortening The effect of high reaction time, saponification rate and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

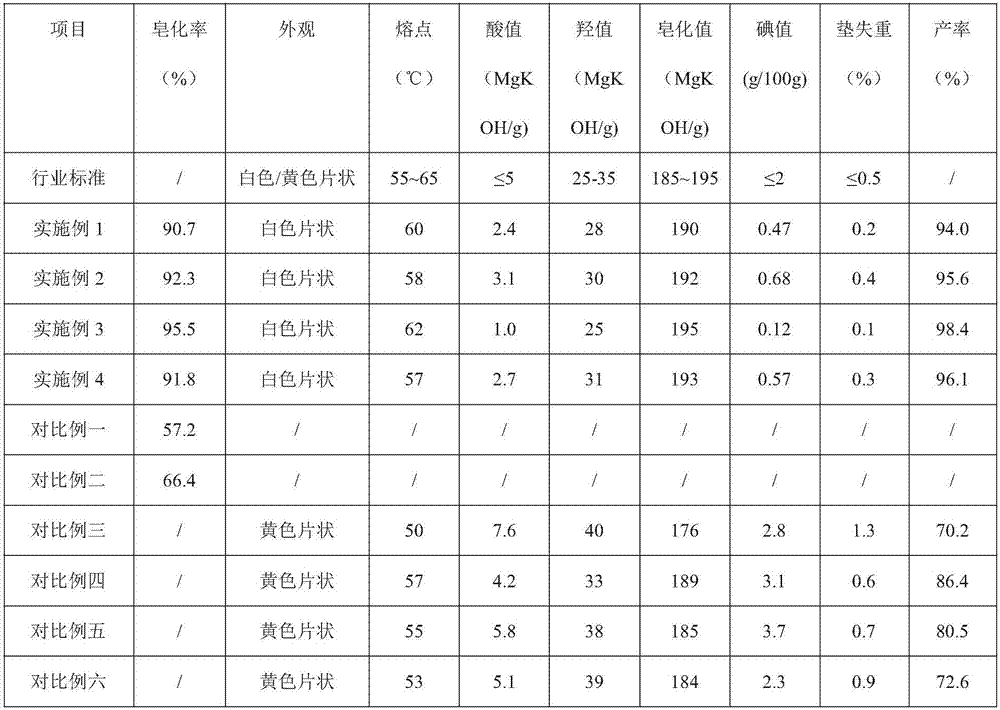

Embodiment 1

[0024] Embodiment 1, the present invention utilizes hydrogenated oil to prepare the method for pentaerythritol stearate

[0025] S1. Add 60 kg of 40% sodium hydroxide aqueous solution and 12 kg of polyethylene glycol-600 to 200 kg of hydrogenated palm oil, control the microwave power to 600w, and the reaction temperature to 65° C., and react for 2 hours under stirring to obtain a saponified product;

[0026] S2, adding a volume concentration of 20% sulfuric acid solution to the saponified product under stirring until the pH of the material is 2, stop the acidification, move the material into a distillation tower, and distill at a temperature of 240 °C and a pressure of 0.070 MPa. Obtain stearic acid;

[0027] S3, drop into described stearic acid 1945.8kg in reactor, heat while stirring, until stearic acid is fully melted and is transparent liquid state, continue to slowly drop into the catalyst of 245.1kg pentaerythritol and stearic acid weight 0.2%, open nitrogen protection a...

Embodiment 2

[0031] Embodiment 2, the present invention utilizes hydrogenated oil to prepare the method for pentaerythritol stearate

[0032] S1. Add 80 kg of 45% sodium hydroxide aqueous solution and 16 kg of polyethylene glycol-600 to 200 kg of hydrogenated palm oil, control the microwave power to 700w, and the reaction temperature to 75° C., and react for 3 hours under stirring to obtain a saponified product;

[0033] S2, adding a volume concentration of 25% sulfuric acid solution to the saponified product under stirring until the pH of the material is 1, stop the acidification, move the material into a distillation tower, and distill at a temperature of 250° C. and a pressure of 0.080 MPa. Obtain stearic acid;

[0034] S3, drop into described stearic acid 2048.3kg in reactor, heat while stirring, until stearic acid is fully melted and is transparent liquid state, continue to slowly drop into the catalyst of 245.1kg pentaerythritol and stearic acid weight 1%, open nitrogen protection an...

Embodiment 3

[0038] Embodiment 3, the present invention utilizes hydrogenated oil to prepare the method for pentaerythritol stearate

[0039] S1. Add 70 kg of 45% sodium hydroxide aqueous solution and 14 kg of polyethylene glycol-600 to 200 kg of hydrogenated palm oil, control the microwave power to 700w, and the reaction temperature to 65° C., and react for 2 hours under stirring to obtain a saponified product;

[0040] S2, under stirring, adding a volume concentration of 20% sulfuric acid solution to the saponified product until the pH of the material is 2, stop the acidification, move the material into a distillation tower, and distill at a temperature of 240 °C and a pressure of 0.080 MPa. Obtain stearic acid;

[0041] S3, drop into described stearic acid 1997.0kg in reactor, heat while stirring, until stearic acid is fully melted and is transparent liquid state, continue to slowly drop into the catalyst of pentaerythritol 245.1kg and stearic acid weight 0.6%, open nitrogen protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com