A kind of method utilizing hydrogenated oil to prepare vinylbisstearamide

A technology of vinyl bisstearamide and hydrogenated oil, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problem of low saponification rate of hydrogenated palm oil saponification reaction, and achieve unmatched reaction conditions Harsh, high saponification rate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

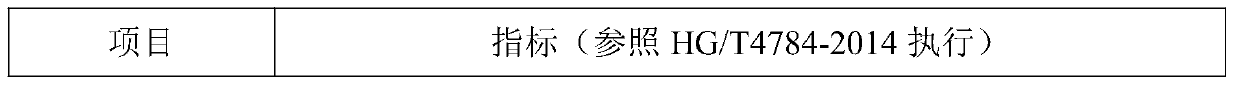

[0026] Embodiment 1 A kind of method utilizing hydrogenated oil to prepare vinylbisstearamide

[0027] The described method utilizing hydrogenated oil to prepare vinylbisstearamide comprises the following steps:

[0028] S1 puts hydrogenated palm oil into the reactor, stirs and adds 30% sodium hydroxide solution and 1% hydrogenated palm oil mass H 3 SiW 12 o 40 -SbF 5 , controlling the ultrasonic power to 280W, the reaction temperature to 70°C, the stirring speed to 200r / min, and the reaction time to 5h, the saponified product was obtained;

[0029] S2 Stir and add sulfuric acid solution with a volume concentration of 15% to the saponified product obtained in step S1 until the pH is 1, stop the acidification, cool to room temperature, let stand for 1h, take the lower layer and place it in a distillation tower at a pressure of 0.08 MPa and a temperature of 230 Distill at ℃ to obtain stearic acid;

[0030] S3 adds the stearic acid obtained in step S2 and the antioxidant T50...

Embodiment 2

[0032] Embodiment 2 A kind of method utilizing hydrogenated oil to prepare vinylbisstearamide

[0033] The described method utilizing hydrogenated oil to prepare vinylbisstearamide comprises the following steps:

[0034]S1 puts hydrogenated palm oil into the reactor, stirs and adds a sodium hydroxide solution with a mass concentration of 35% and hydrogenated palm oil with 2% H 3 SiW 12 o 40 -SbF 5 , control the ultrasonic power to 320W, the reaction temperature is 75°C, the stirring speed is 250r / min, the reaction time is 6h, and the saponified product is obtained;

[0035] S2 Stir and add a volume concentration of 20% sulfuric acid solution to the saponified product obtained in step S1 until the pH is 1.5, stop the acidification, cool to room temperature, let stand for 1.5h, take the lower layer liquid and place it in a distillation tower at a pressure of 0.08 MPa and a temperature of Distill at 240°C to obtain stearic acid;

[0036] S3 adds the stearic acid obtained in ...

Embodiment 3

[0038] Embodiment 3 A kind of method utilizing hydrogenated oil to prepare vinylbisstearamide

[0039] The described method utilizing hydrogenated oil to prepare vinylbisstearamide comprises the following steps:

[0040] S1 puts hydrogenated palm oil into the reactor, stirs and adds 40% sodium hydroxide solution and 3% hydrogenated palm oil quality H 3 SiW 12 o 40 -SbF 5 , controlling the ultrasonic power to 360W, the reaction temperature to 80°C, the stirring speed to 300r / min, and the reaction time to 7h, to obtain a saponified product;

[0041] S2 Stir and add a sulfuric acid solution with a volume concentration of 25% to the saponified product obtained in step S1 until the pH is 2, stop the acidification, cool to room temperature, let stand for 2h, take the lower layer and place it in a distillation tower at a pressure of 0.09MPa and a temperature of 250 Distill at ℃ to obtain stearic acid;

[0042] S3 adds stearic acid obtained in step S2 and antioxidant T501 with 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com