Method for saponifying P204

A technology of saponification and saponification reaction, applied in directions such as the improvement of process efficiency, can solve problems such as control of unfavorable organic phase saponification rate, difficulty in phase separation of saponified organic phase, difficulty in metering of lime milk alkalinity, etc., to achieve environmental protection , Reduce the lime digestion process, saponification rate and stable effect

Active Publication Date: 2014-09-03

YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After the saponification is completed, the volume of the aqueous phase is too large, which will lead to a large loss of the organic phase discharged with the discarded water

Natural lime raw materials often contain a lot of impurities, such as using milk of lime for saponification, because the impurities cannot be effectively removed, the insoluble impurity elements in the lime will have a negative impact on the extraction process, making it difficult to separate the saponified organic phase, and resulting in a high concentration of impurities Exceeding the standard, affecting product quality

In addition, there are certain difficulties in the measurement of the alkalinity of milk of lime, which is not conducive to the control of the saponification rate of the organic phase in production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

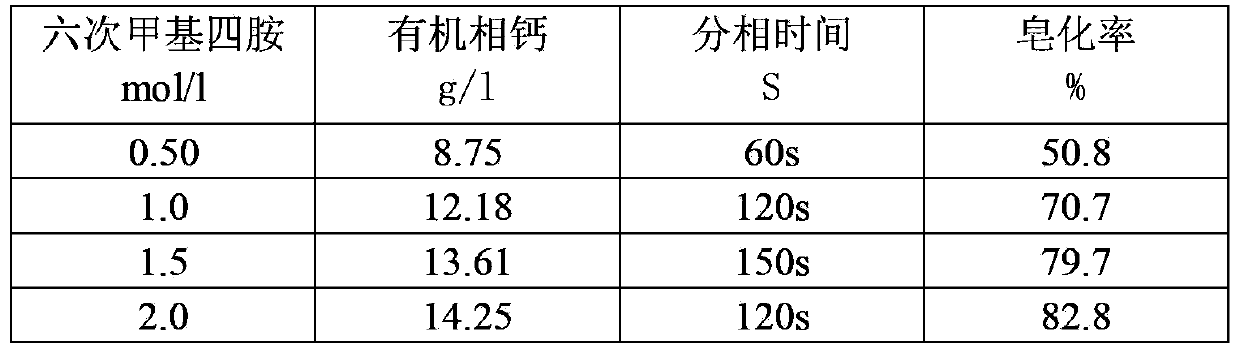

[0021] The basic test data below embodies a group of specific embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

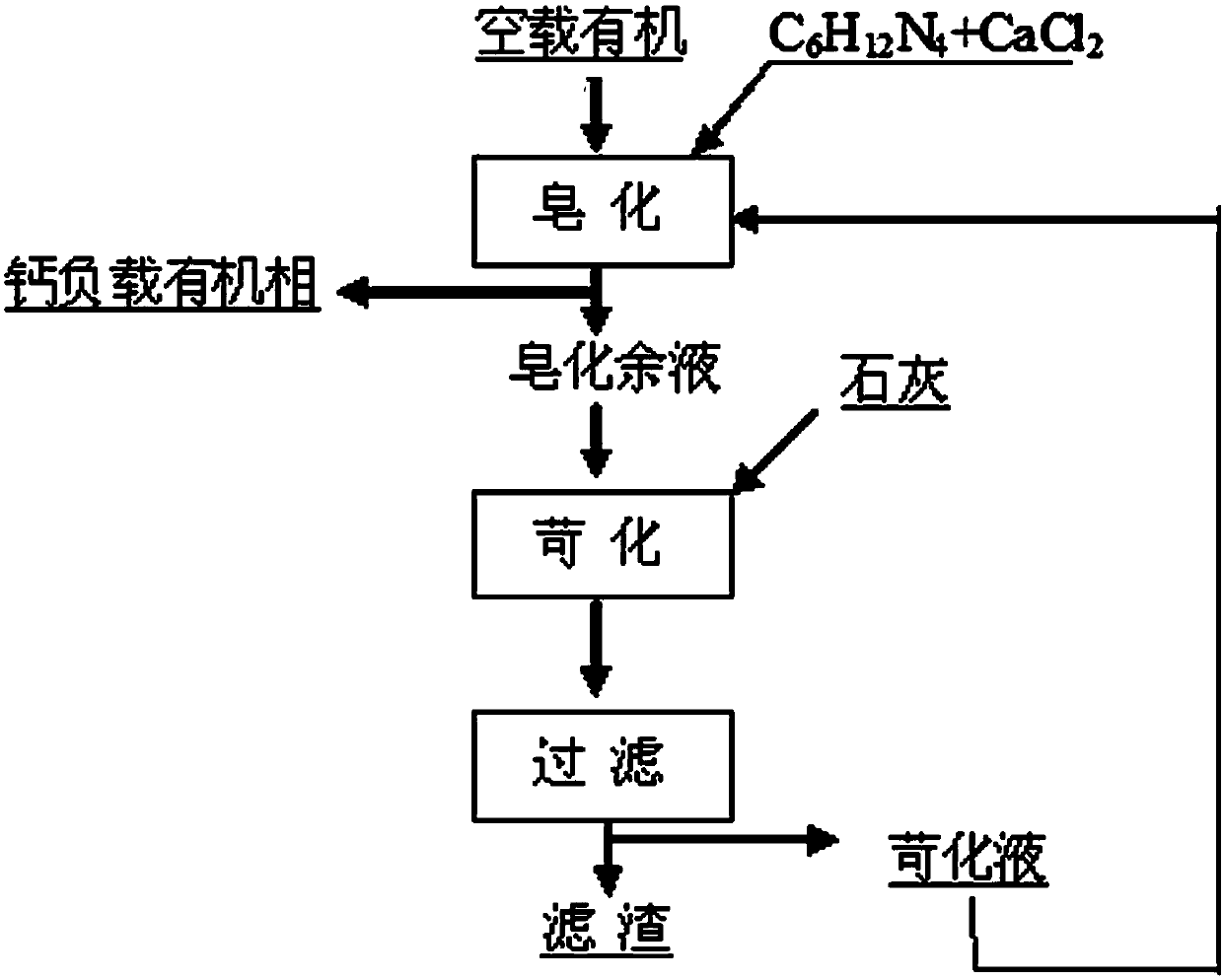

The invention relates to a method for saponifying P204. The invention belongs to the technical field of saponification and extraction processes in wet process smelting of non-ferrous metals and rare earth, and specifically relates to a method for saponifying a P204 extraction agent. According to the method disclosed by the invention, hexamethylenetetramine is taken as an auxiliary agent, calcium chloride is adopted for directly performing saponification reaction on the P204 at normal temperature, a saponification residual solution is neutralized by using lime and then circulated to a saponification process step for use, and the hexamethylenetetramine and the calcium chloride in the quantity required for reaction are supplemented according to the entrainment loss of filter residues during the lime neutralization process. According to the method disclosed by the invention, the higher and stable saponification rate can be obtained, and the first-stage saponification rate can be above 70%; and the problems of ammonia nitrogen pollution and the like existing in the saponification process for a long time are thoroughly solved, the demands for high-energy consumption products (liquid alkali and ammonia) are reduced, and the method is conductive to environmental production and sustainable development.

Description

technical field [0001] The invention belongs to the technical field of saponification and extraction process in wet smelting of nonferrous metals and rare earths, and specifically relates to a method for saponifying P204 extractant. technical background [0002] At present, the separation of rare earths in my country mainly uses extraction agents such as P204. Before use, the extractant must first be saponified with liquid caustic soda (sodium hydroxide solution) or ammonia water. After saponification, the extractant reacts with the rare earth chloride solution to generate the rare earth-loaded extractant and ammonia (sodium) salt solution, the rare earth-loaded extractant is exchanged and purified by rare earth in a multi-stage extraction device, and then subjected to acid stripping to obtain a water-phase rare earth feed liquid. Saponification of extractant is the core process of saponification extraction technology. At present, the saponification process of extractant m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B3/38

CPCY02P10/20

Inventor 杨桂芬王群赵福瑞

Owner YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com