Long-acting slow-release coated urea special for lactating dairy cows, and preparation method and application thereof

A technology for slow-release bags and dairy cows, which is applied in the fields of application, animal feed, molding or processing of animal feed, etc. It can solve problems such as ammonia poisoning of ruminants, reduce the utilization efficiency of ruminants, and environmental pollution, so as to promote growth and increase protein. Utilization rate, the effect of saving protein source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

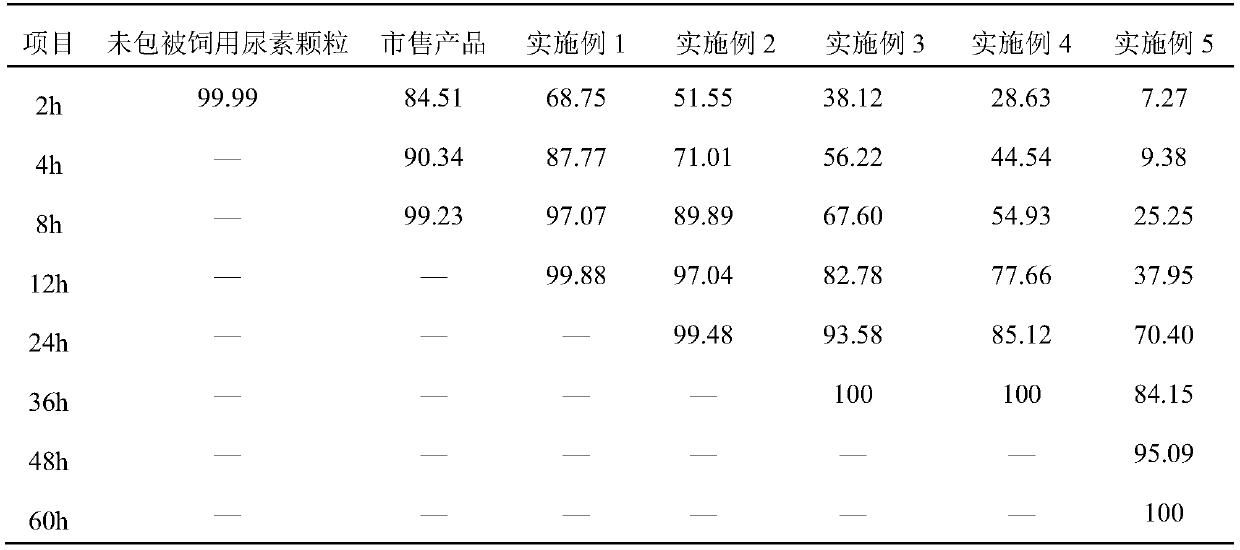

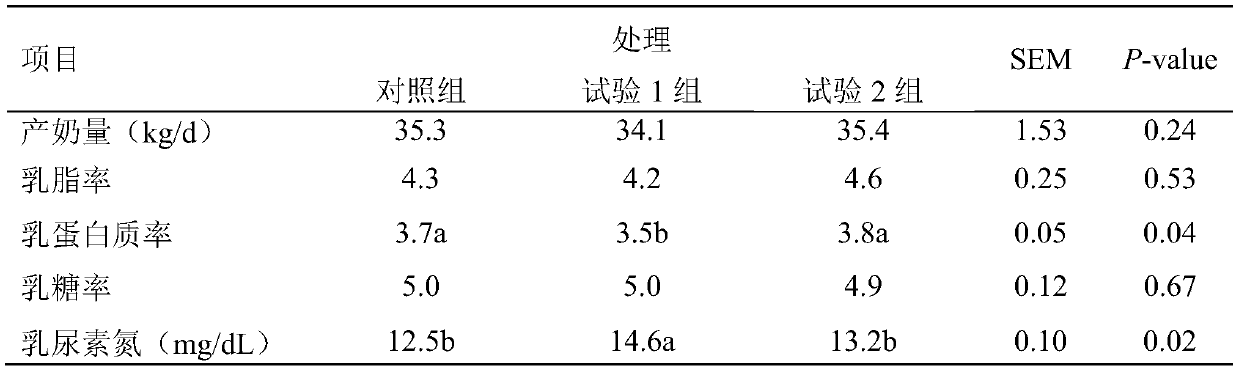

Examples

Embodiment 1

[0020] A special long-acting slow-release coated urea for lactating dairy cows, which consists of a core material and a wall material, including 90% of the core material and 10% of the wall material by mass fraction. The core material is feed urea granules, with a total nitrogen content of 46%; the wall material is a layer, composed of ethyl cellulose and polyacrylic acid resin IV, including 65% ethyl cellulose by mass fraction , Polyacrylic resin No. IV 35%.

[0021] Specifically, the preparation method of long-acting slow-release coated urea dedicated for lactating dairy cows comprises the following steps:

[0022] The urea granule for feeding is used as the core material, and it is coated by a DPL-II multifunctional granulating and coating machine. Put the core material into the bottom-sprayed moving bed, raise the moving bed, mix the wall material with plasticizer and anti-sticking agent according to a certain proportion, and then dissolve it in 95% ethanol solution to ma...

Embodiment 2

[0024] A special long-acting slow-release coated urea for lactating milk cows, which consists of a core material and a wall material, including 90% of the core material and 10% of the wall material by mass fraction. The core material is feed urea granules, with a total nitrogen content of 46%; the wall material is a layer, composed of ethyl cellulose and polyacrylic acid resin IV, including 65% ethyl cellulose by mass fraction , Polyacrylic resin No. IV 35%.

[0025] Specifically, the preparation method of long-acting slow-release coated urea dedicated for lactating dairy cows comprises the following steps:

[0026] The urea granule for feeding is used as the core material, and it is coated by a DPL-II multifunctional granulating and coating machine. Put the core material into the bottom-sprayed moving bed, raise the moving bed, mix the wall material with plasticizer and anti-sticking agent according to a certain proportion, and then dissolve it in 95% ethanol solution to mak...

Embodiment 3

[0028] A special long-acting slow-release coated urea for lactating dairy cows, which consists of a core material and a wall material, including 90% of the core material and 10% of the wall material by mass fraction. The core material is feed urea granules with a total nitrogen content of 46%; the wall material is one layer and is composed of ethyl cellulose.

[0029] Specifically, the preparation method of long-acting slow-release coated urea dedicated for lactating dairy cows comprises the following steps:

[0030] The urea granule for feeding is used as the core material, and it is coated by a DPL-II multifunctional granulating and coating machine. Put the core material into the bottom-sprayed moving bed, raise the moving bed, mix the wall material with plasticizer and anti-adhesive agent in a certain proportion, and then dissolve it in 95% ethanol solution, and prepare the wall material with a content of 5% coating solution. Set the fan frequency to 30Hz, the air inlet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com