Method for preparing low/zero-trans fatty acid shortening by enzymatic interesterification

An enzymatic ester and shortening technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of affecting human health, unable to solve the typical enrichment defects of triglycerides, and producing trans fatty acids, etc. Prospects for industrial development, mild reaction conditions, and the effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: lard and palm stearin enzymatic transesterification test

[0022] Accurately weigh 10g of a mixture of lard and palm stearin containing 25%, 33%, 40%, 50%, 60%, 67%, and 75% of palm stearin in a round bottom flask, mix well, and vacuum dehydrate Degassing, then add respectively immobilized lipase LipozymeRM IM 2%, 4%, 6%, 8%, 10%, 12% (by oil weight), in rotary evaporation reactor (vacuum degree 0.09MPa, rotating speed 80r / min), the reaction time is 0.5h, 1h, 1.5h, 2h, 3h, the temperature is 50°C, 60°C, 70°C, 80°C, 90°C, the full test experiment is carried out under this condition, after the reaction Remove the immobilized lipase by suction filtration to obtain the transesterification product. Taking the change of solid fat content (SFC) of the product at 20°C as an index, the ideal technical parameters are obtained: reaction temperature 60°C-90°C, enzyme addition 6%-12%, reaction time 1h-3h. Under these conditions, the transesterification reaction reac...

Embodiment 2

[0023] Example 2: Lard and extreme hydrogenated soybean oil enzymatic transesterification experiment

[0024] Accurately weigh 10g of a mixture of lard and extremely hydrogenated soybean oil containing 25%, 33%, 40%, 50%, 60%, 67%, and 75% of extremely hydrogenated soybean oil in a round-bottomed flask, mix well, Vacuum dehydration and degassing, then respectively add immobilized lipase Lipozyme RM IM 2%, 4%, 6%, 8%, 10%, 12% (by oil weight), in a rotary evaporation reactor (vacuum degree 0.09MPa, The reaction is carried out at a rotation speed of 80r / min), the reaction time is 0.5h, 1h, 1.5h, 2h, 3h, the temperature is 50°C, 60°C, 70°C, 80°C, 90°C, and the full test is carried out under this condition. After the reaction was completed, the immobilized lipase was removed by suction filtration to obtain the transesterified product. Taking the change of solid fat content (SFC) of the product at 20°C as an index, the ideal technical parameters were obtained: reaction temperature...

Embodiment 3

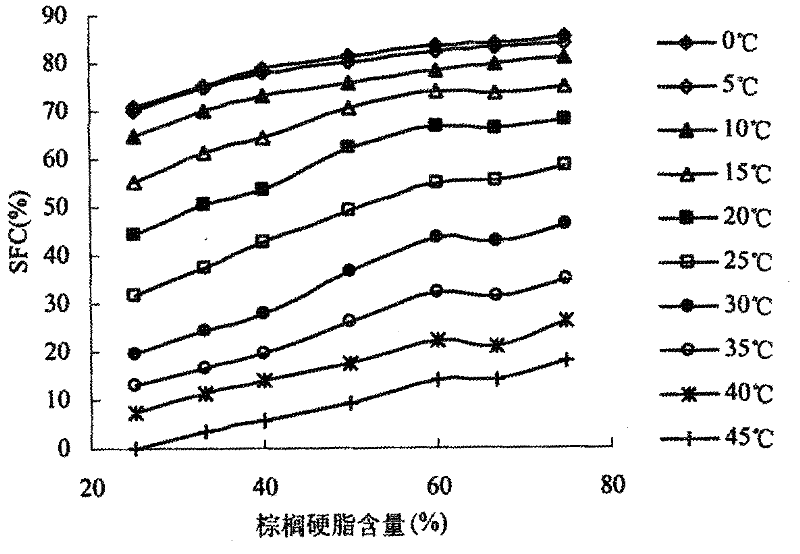

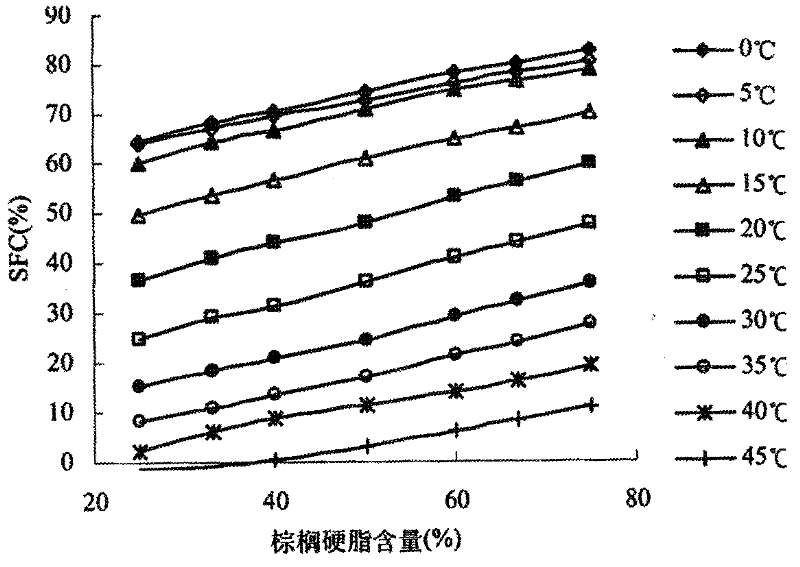

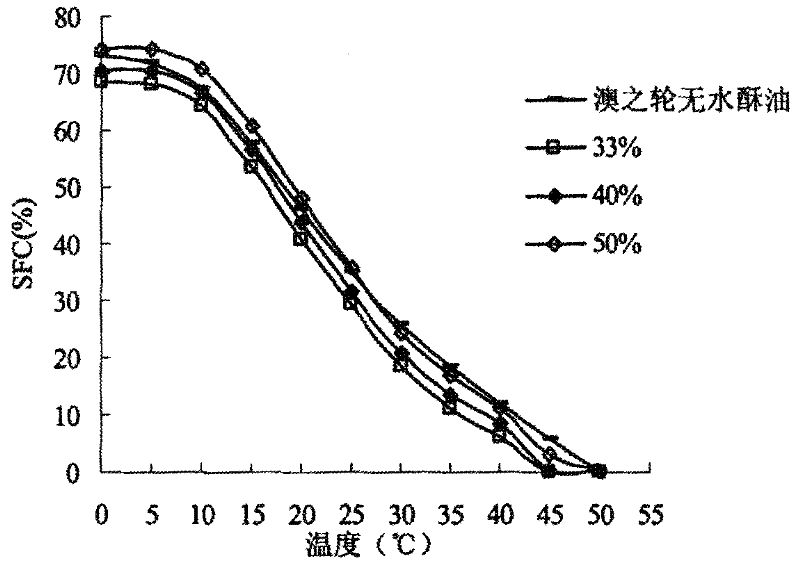

[0025] Embodiment 3: the analysis of compatibility

[0026] Get a certain amount of lard and palm stearin to mix in proportion respectively, the content of palm stearin is respectively 25%, 33%, 40%, 50%, 60%, 67%, 75%, measure the SFC before and after its transesterification and Draw an isotherm curve. From the isotherm curves before and after transesterification, it can be seen that the compatibility of lard and palm stearin mixture before transesterification is poor, and each isotherm curve is basically not a straight line, especially in the range of 15°C to 35°C, the linear relationship is relatively poor. When the content of palm stearin is 50% to 67%, there are obvious signs of convexity, which is due to the great difference in triglyceride composition and homogeneous polymorphism between lard and palm stearin, lard lard triglyceride The composition is SPO, and the crystallization is mainly in the β-type crystal form, while the main triglycerides of palm stearin are POP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com