Method of producing full-cotton elasticity non-ironing face fabric

A production method and elastic technology, applied in biochemical fiber treatment, fabrics, textiles, etc., can solve the problems of large strength drop and loss of strength, and achieve the effects of increased strength, good wear resistance, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

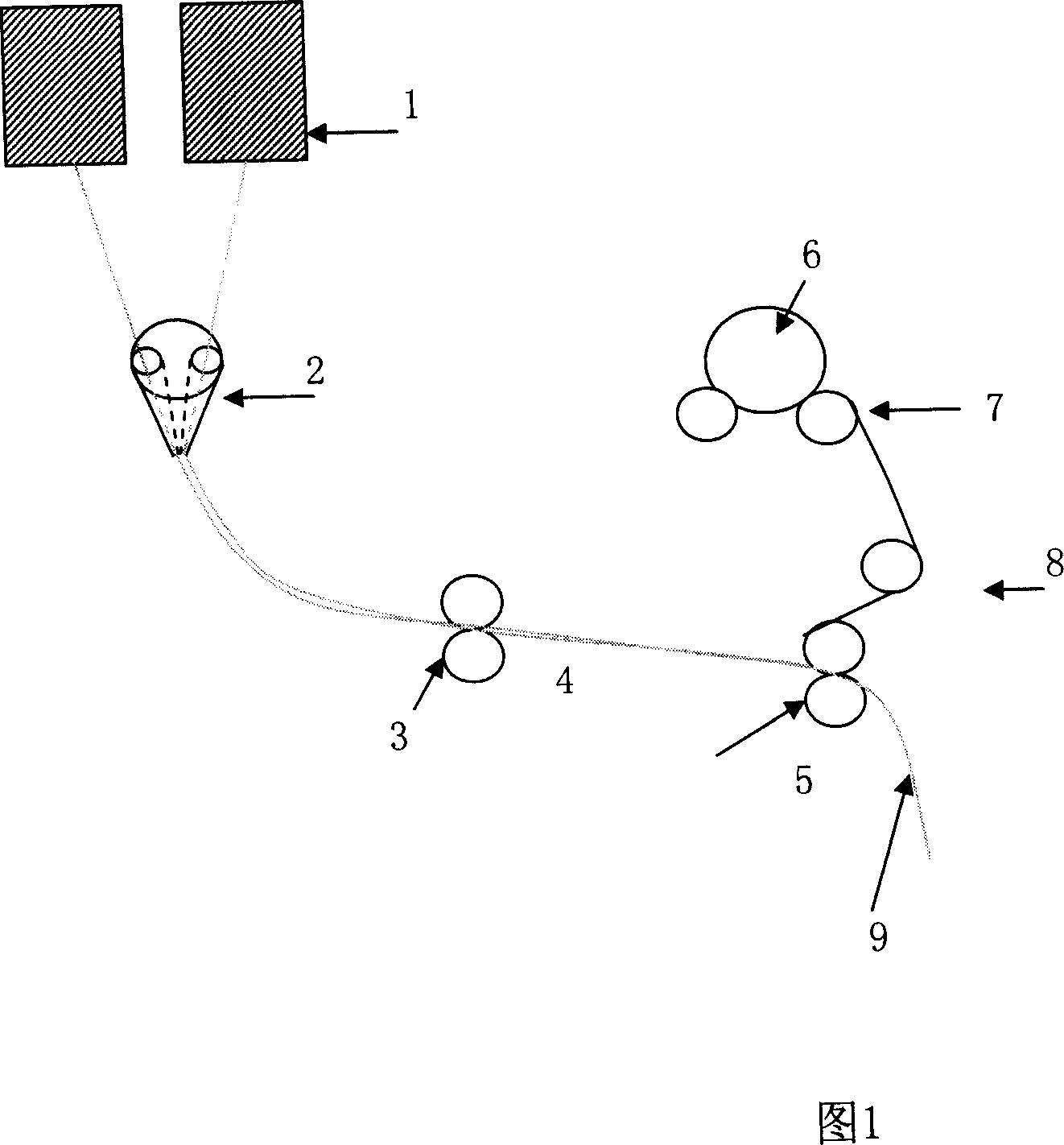

[0023] Embodiment 1: a kind of production method of cotton elastic non-ironing fabric, comprises following production process: (1) spinning, comprises blowing, carding, pre-doubling, sliver doubling, combing, end doubling, roving front road process, then the two cotton yarn slivers 1 are fed from the back roller 3 through the double-port bell mouth 2 with a distance of 4mm, and the separation state of the two cotton yarn slivers 1 is kept in the drafting zone 4, and the two cotton yarn slivers 1 are separated in the twisting triangle zone. The cotton yarn sliver 1 is twisted respectively, and the core filament 6 of the elastic filament is fed through the godet roller 7 through the godet wheel 8 from the front roller 5, and a set of drafting gears (not shown) are set at the front roller 5, Combined with the godet roller 7 to form a drafting mechanism, the core filament 6 of the elastic filament is fed from the front roller 5, and the filament core 6 is located in the middle of t...

Embodiment 2

[0027] Embodiment two: a kind of production method of all-cotton elastic non-ironing fabric comprises the following production steps: (1) spinning, including blowing, carding, pre-doubling, sliver doubling, combing, finishing and roving front road process, then the two cotton yarn slivers 1 are fed from the back roller 3 through the double-port bell mouth 2 with a distance of 6 mm, and the two cotton yarn slivers 1 are kept separated in the drafting zone 4. The cotton yarn sliver 1 is twisted respectively, and the core filament 6 of the elastic filament is fed through the godet roller 7 through the godet wheel 8 from the front roller 5, and a set of drafting gears (not shown) are set at the front roller 5, Combined with the godet roller 7 to form a drafting mechanism, the core filament 6 of the elastic filament is fed from the front roller 5, and the filament core 6 is located in the middle of the two cotton yarn strands 1, and then passes through the speed difference between t...

Embodiment 3

[0031] Embodiment three: a kind of production method of all-cotton elastic non-ironing fabric comprises the following production steps: (1) spinning, including blowing, carding, pre-doubling, sliver doubling, combing, finishing and roving front road process, then the two cotton yarn slivers 1 are fed from the back roller 3 through the double-port bell mouth 2 with a spacing of 8mm, and the separation state of the two cotton yarn slivers 1 is kept in the drafting zone 4, and the two cotton yarn slivers 1 are separated in the twisting triangle zone. The cotton yarn sliver 1 is twisted respectively, and the core filament 6 of the elastic filament is fed through the godet roller 7 through the godet wheel 8 from the front roller 5, and a set of drafting gears (not shown) are set at the front roller 5, Combined with the godet roller 7 to form a drafting mechanism, the core filament 6 of the elastic filament is fed from the front roller 5, and the filament core 6 is located in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com