System for continuously using resist stripper liquid based on nanofiltration

A technology of resist and stripper, which is applied in ultrafiltration, semipermeable membrane separation, photoplate making process of patterned surface, etc., can solve the problems of low heat resistance, difficult filtration speed, and impracticality, and achieve low Low cost and environmental load, and the effect of maintaining stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

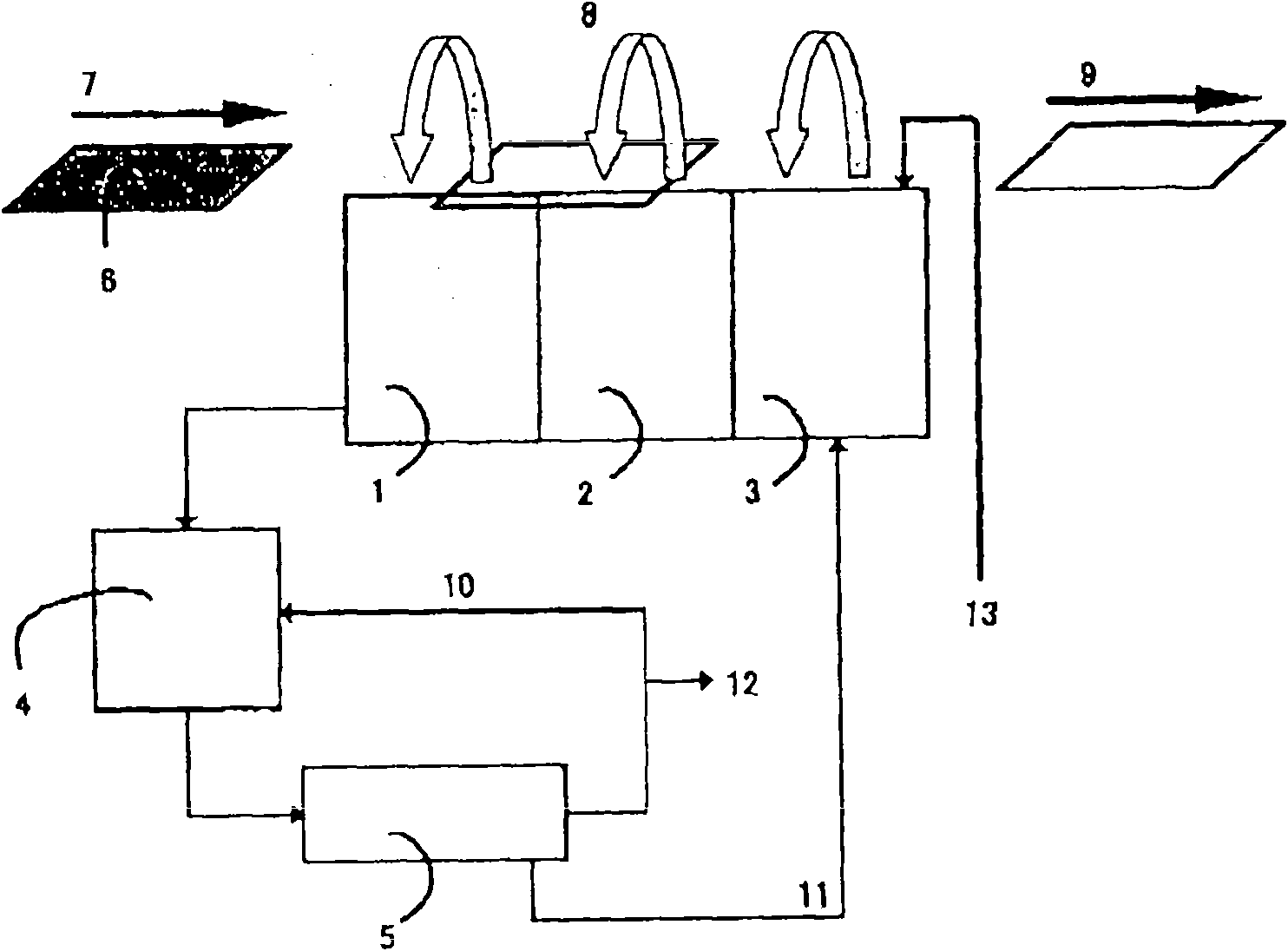

[0043] 100 parts of p-cresol novolak resins are added with 25 parts of positive optical protective agent of naphthoquinone diazide, coated on the glass substrate, and dried to make a 5 μm thick glass substrate with a resist film. figure 1 Place the resist stripping liquid with the composition shown in Table 1 on the resist stripping device, and use as a filter, an alumina aggregate with an average pore diameter of 4 nm and a graded molecular weight of 2000 measured with polyethylene glycol. Titanium, area 1.2m 2 tubular ceramic filter. On the filter surface, the flow velocity of the concentrated stripping liquid in the direction parallel to the filter surface is 2m / s, and the flow velocity of the processed stripping liquid side after filtration is not controlled and allowed to flow out freely. In addition, on the side of the stripping liquid containing the resist component of the filter, the inflow pressure of the pump entering the filtration process was set so that a pressur...

Embodiment 2

[0054] Resist stripping was performed in the same operation method as in Example 1, except that a ceramic filter having the same material, an average pore diameter of 2 nm, and a fractional molecular weight of 1,000 was used as a filter.

[0055] [table 3]

[0056] Concentration of resist components in the stripping bath of Example 2

[0057] Running time (minutes)

0

100

1000

2000

3000

Blocking rate (%)

92

92

92

92

Strip tank 1 concentration

0

0.07

0.36

0.46

0.53

Stripping Tank 2 Concentration

0

0.001

0.04

0.1

0.16

Strip tank 3 concentration

0

0.0

0.02

0.07

0.12

Filtrate outflow velocity (L / h m 2 )

6

6

3

3

3

[0058] (The unit of resist component concentration is mass %)

[0059] After 100 minutes, the resist component concentration of the stripping solution containing resist compo...

Embodiment 3

[0061] The resist stripping was carried out in the same operation method as in Example 1, except that a ceramic filter having an average pore diameter of 5 nm and a fractional molecular weight of 4,000 having the same material as the filter was used.

[0062] [Table 4]

[0063] Concentration of resist components in the stripping bath of Example 3

[0064] Running time (minutes)

0

100

1000

2000

3000

Blocking rate (%)

71

72

72

72

Strip tank 1 concentration

0

1.9

1.8

1.8

1.8

Stripping Tank 2 Concentration

0

1.6

1.5

1.5

1.5

Strip tank 3 concentration

0

1.4

1.3

1.3

1.3

Filtrate outflow velocity (L / h m 2 )

22

20

18

18

18

[0065] (The unit of resist component concentration is mass %)

[0066] After 100 minutes, the resist component concentration of the stripping solution containing the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com