High breathable and high tearing fine denier spun-laced novel material and process for its production

A new type of material, high air permeability technology, applied in the deburring device, textile and paper making, fiber treatment, etc., can solve the problems of uneven vertical and horizontal tearing strength, poor finish of finished leather, poor hand feeling and imitation, etc. Fuzzing phenomenon, good entanglement effect, and improved imitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The new high-breathability and high-tear fine denier spunlace material of the present invention is prepared from the following components in weight percentage: 70% of highly hydrophilic polyester with a specification of 1.56dtex×38mm, 30% of nylon with a specification of 1.56dtex×38mm .

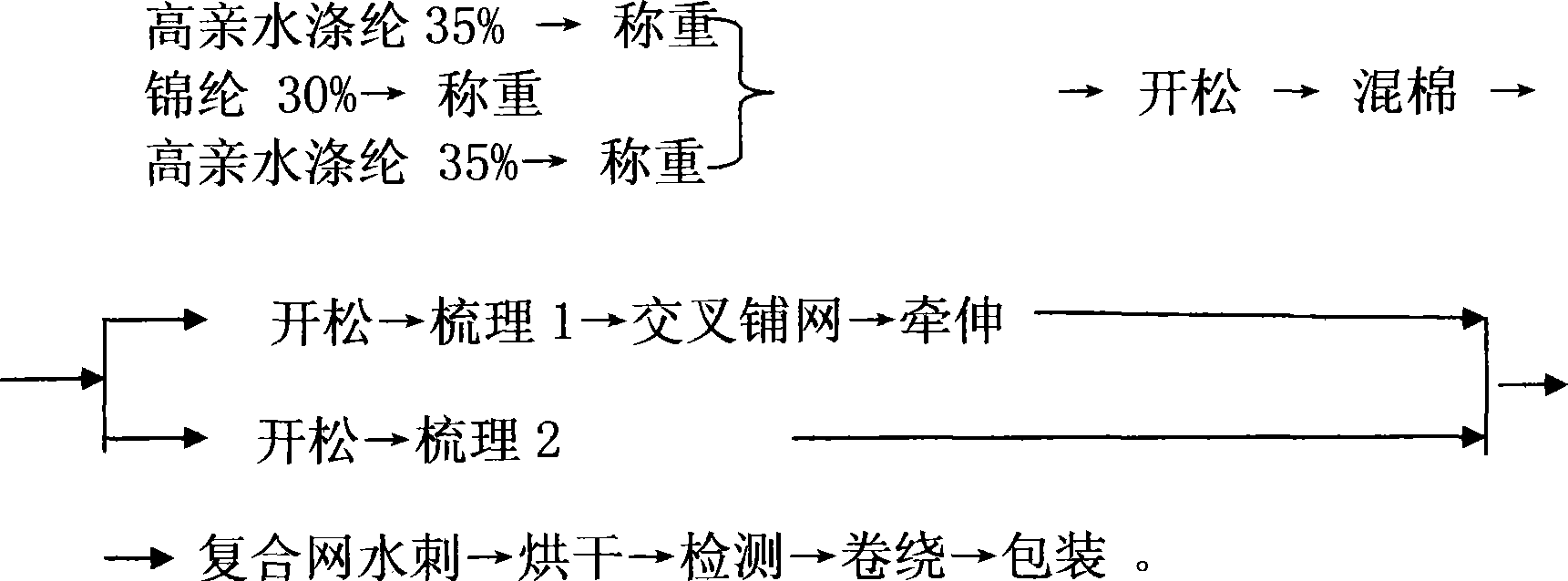

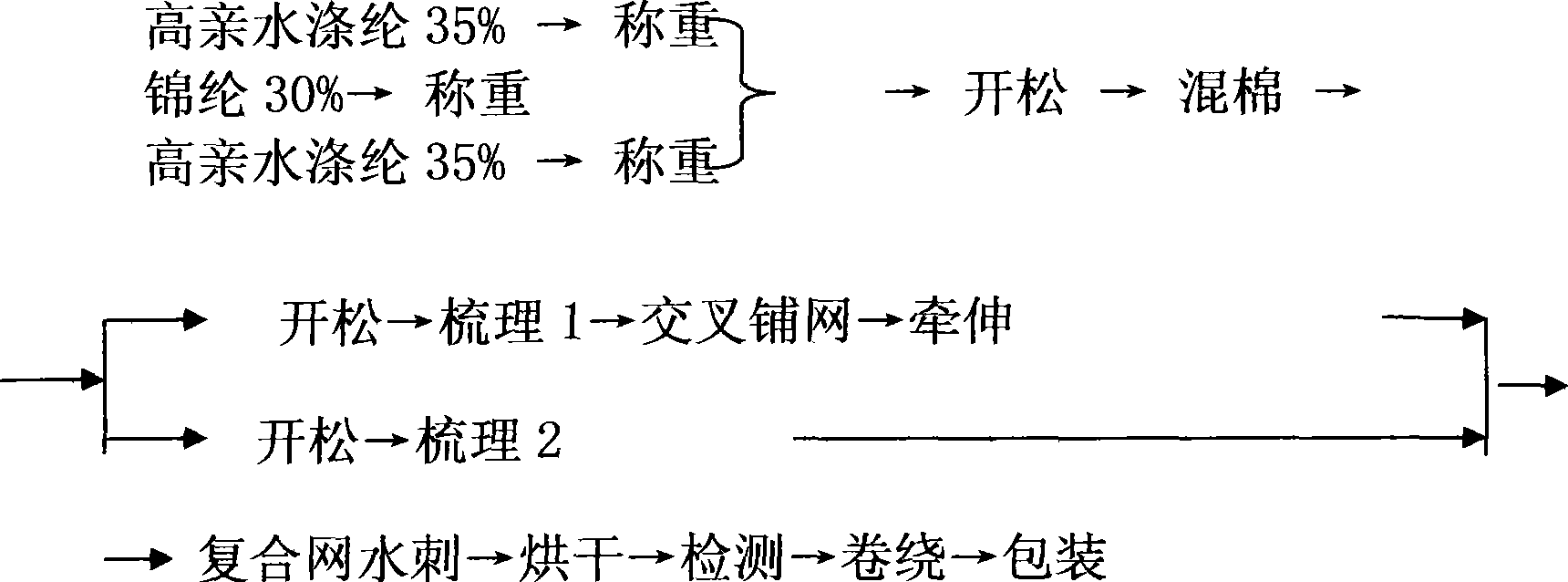

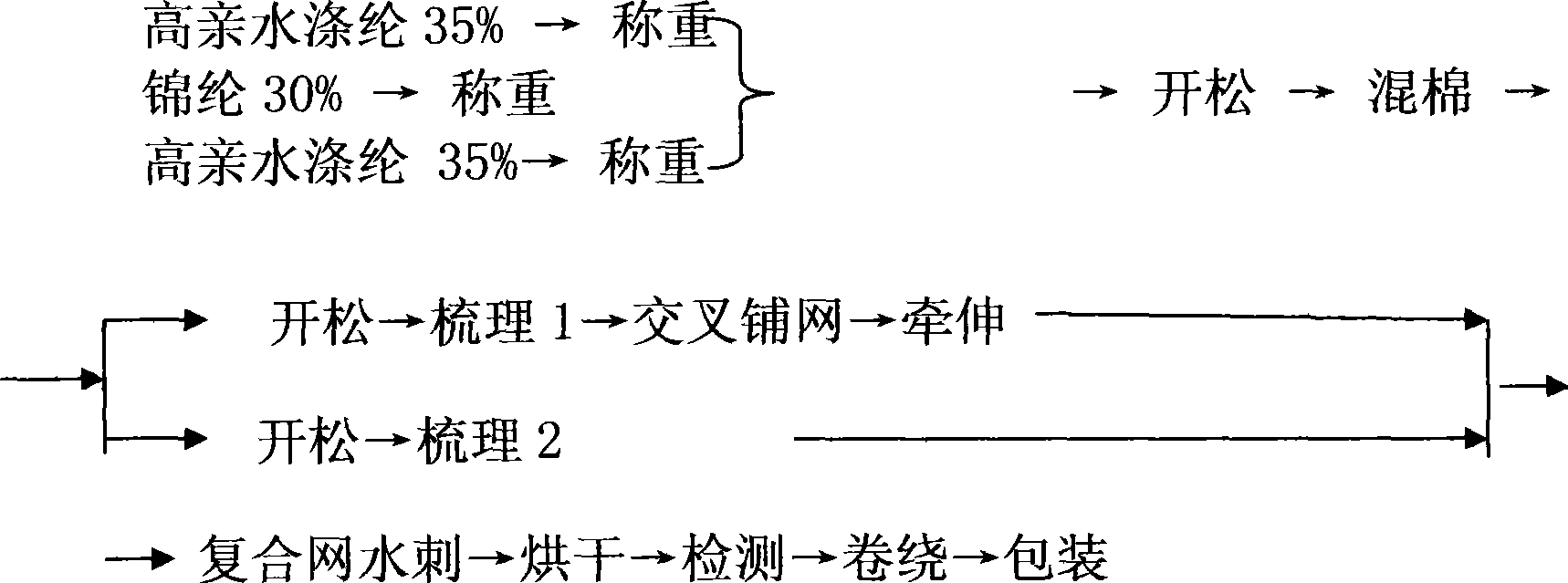

[0017] The production process of the high-breathability and high-tear fine-denier spunlace novel material of the present invention comprises the following steps:

[0018]

[0019] Among them, in the carding 1 process, the work roll of the main cylinder is 100m / min, the stripping roll of the main cylinder is 185m / min, the speed of the main cylinder is 1150m / min, and the feeding weight is 25g / m 2 .

[0020] Carding 2 process, main cylinder work roll is 90m / min, main cylinder stripping roll is 165m / min, main cylinder speed is 1100m / min, feed weight is 25g / m 2 .

[0021] The cross-lapping process adopts the composite process of direct feeding cross-lapping and online cohesive netting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com