Nickel residual electrode treatment method

A treatment method and nickel anode technology, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of poor crushing effect of nickel anode, low screening rate of anode slime, and long process flow, etc., to reduce flue gas Treatment cost, complete separation of nickel and copper, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

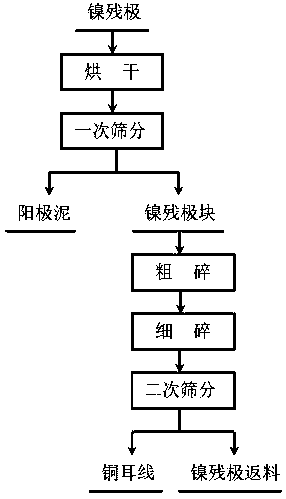

[0020] A kind of nickel anode residue treatment method provided by the present embodiment, the specific operation process is:

[0021] Step 1. After concentrating the nickel residue produced in the electrolysis process of the nickel diaphragm, the continuous fixed

[0022] Feed the material, bake at 70°C for 10 hours, and perform a sieve after the moisture content of the anode slime on the surface of the nickel anode is 12wt%, to remove the anode slime. Select a single sieve hole area of 100mm for one screening 2 The circular sieve holes are used to obtain anode slime and nickel anode residue, and the anode slime is sent to the anode slime silo for storage;

[0023] Step 2. First coarsely crush the residual nickel pieces in step 1 until the particle size is ≤150mm, so that part of the copper ears

[0024] The wire is stripped from the nickel anode block, and then finely crushed to a particle size of ≤35mm, so that the copper ear wire in the nickel anode is completely strip...

Embodiment 2

[0029] A kind of nickel anode residue processing method provided by this embodiment, its implementation steps are roughly the same as embodiment 1, the difference is:

[0030] Step 1: Bake the nickel anode at 120°C for 4 hours until the anode slime on the surface of the nickel anode contains water

[0031] A sieve is carried out after the rate is 8wt%; a single sieve area is selected as 400mm for a sieve 2 square sieve holes;

[0032] In step 2: coarse particle size < 120mm, fine particle size < 20mm;

[0033] The main technical index of the nickel anode after adopting the present embodiment method to process is:

[0034] Anode slime removal rate: 95.3%, copper lug wire sorting rate: 98.3%, anode slime carrying rate of nickel anode scrap return: 9.97wt%.

Embodiment 3

[0036] A kind of nickel anode residue processing method provided by this embodiment, its implementation steps are roughly the same as embodiment 1, the difference is:

[0037] Step 1: Bake the nickel anode at 100°C for 6 hours, and wait until the anode slime on the surface of the nickel anode contains water

[0038] A sieve is carried out after the rate is 10wt%; a single sieve area is selected as 150mm for a sieve 2 circular sieve holes;

[0039] In step 2: coarse particle size < 80mm, fine particle size < 10mm;

[0040] The main technical index of the nickel anode after adopting the present embodiment method to process is:

[0041] Anode slime removal rate: 96%, copper lug wire sorting rate: 98.7%, anode slime carrying rate of nickel anode scrap return: 9.01wt%.

[0042] The above results show that the method of the present invention is used to treat the nickel anode residue, the nickel anode residue crushing effect is good, the nickel-copper separation is complete, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com