Rotary bronzing machine

A circular bronzing machine and circular pressing technology, applied in the printing field, can solve problems such as mismatch between the anodized aluminum foil and the printing plate, increased running resistance of the aluminum foil, and inability to complete bronzing on materials, so as to reduce procurement limitations and improve printing quality Improve and increase the effect of the scope of purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

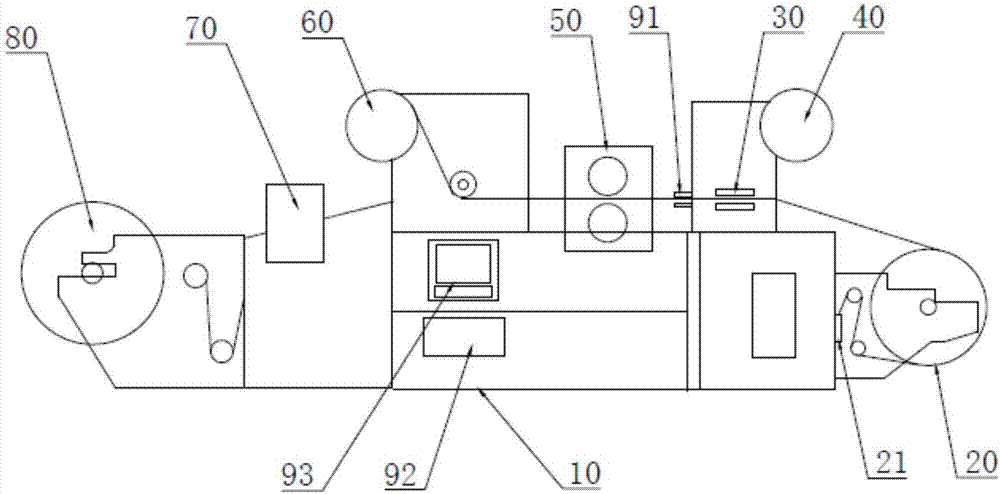

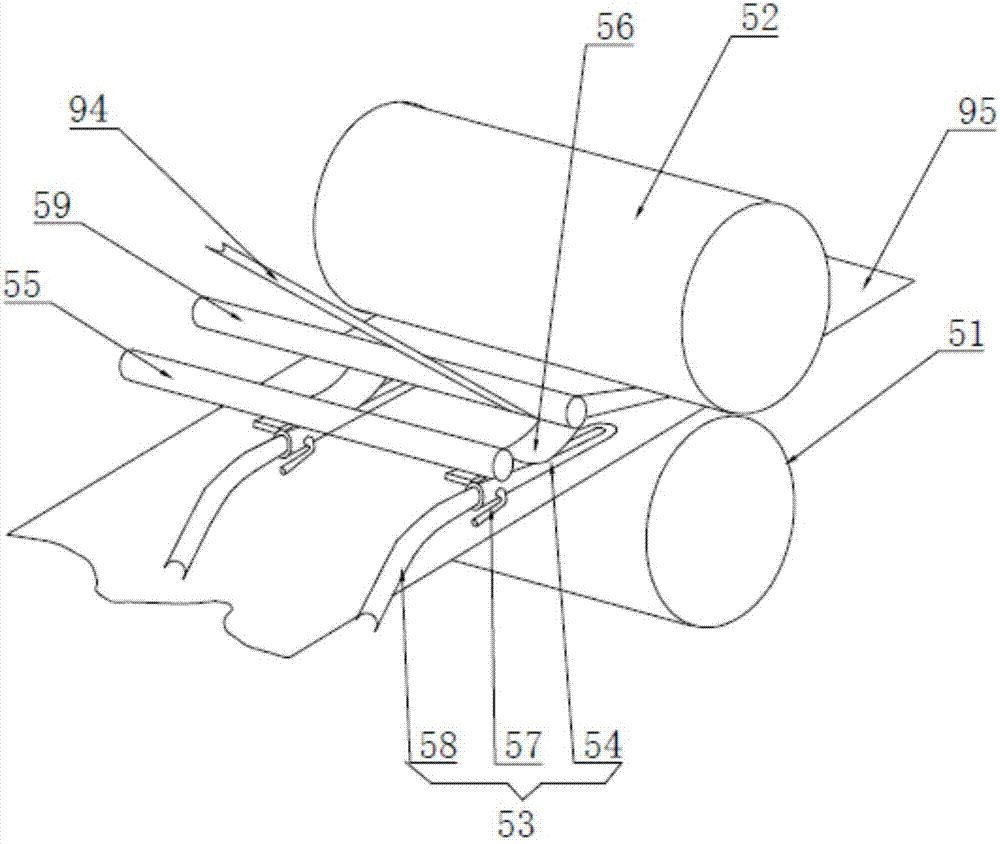

[0031] Such as figure 1 and figure 2 As shown, a round stamping machine includes a frame 10 and an unwinding device 20, a deviation correcting device 30, a bronzing material discharging device 40, a bronzing device 50, and a waste film that are successively arranged on the frame along the moving direction of the substrate. The receiving device 60, the drying device 70 and the winding device 80; the bronzing device 50 includes a printing roller 51, an embossing roller 52 and a cooler 53, and the ironing material is arranged between the printing roller 51 and the embossing roller 52 Between, the substrate is arranged between the hot material and the printing roller 51, the cooler 53 includes an air delivery nozzle 54 opposite to the moving direction of the substrate, and the air delivery nozzle 54 is arranged between the hot material and the printing roller between the above-mentioned substrates; between the bronzing device 50 and the correction device 30, a sensor 91 for dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com