Method for preparing high-intrinsic-degree graphene by electrolysis

A graphene and electrolyte technology, applied in the field of electrolytic preparation of high intrinsic degree graphene, achieves the effects of low cost, easy availability of raw materials, and convenience for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

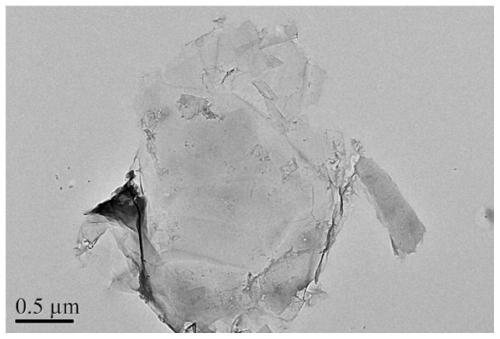

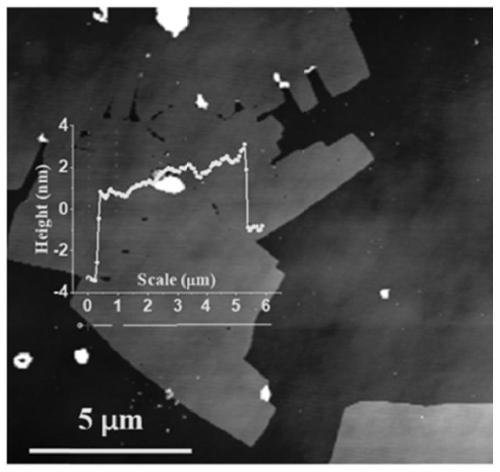

Image

Examples

Embodiment 1

[0045] A kind of preparation method of high intrinsic degree graphene is characterized in that, the method comprises the following steps:

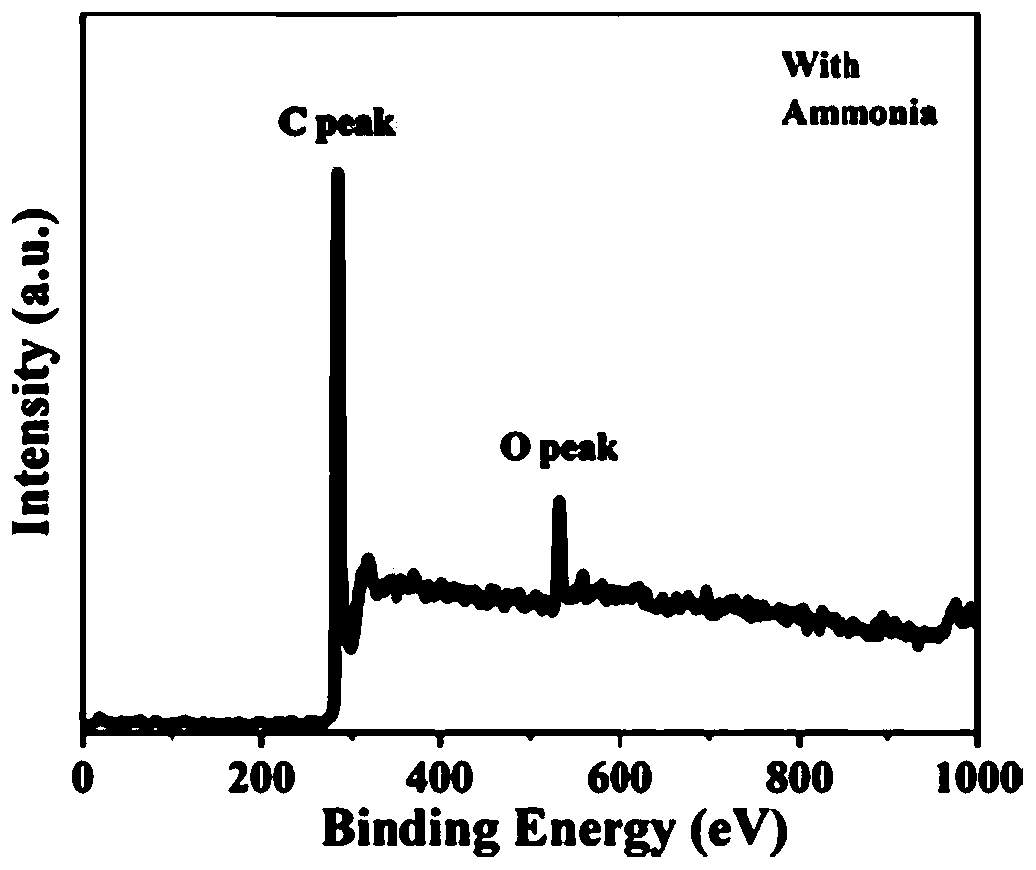

[0046] (1) Preparation of reactants: graphite foil is pressed into graphite flakes, and the thickness of the pressed sheet is 3mm, as the positive electrode reactant A during electrolysis; the platinum electrode is selected as the negative electrode of electrolysis; ammonium sulfate is selected to be made into 1mol / L Ammonium sulfate solution B; in B solution according to 2% volume ratio, promptly every 100mL B solution adds the ammoniacal liquor of the 30% mass fraction of 2mL to control the pH value of B solution to be 9, and mixed solution uniform velocity stirs 15 minutes, and in Ultrasonic at room temperature (25°C) with a power of 50W for 5 minutes to obtain alkaline electrolyte solution C;

[0047] (2) Reaction stripping: place the electrolyte device in a constant temperature environment at 0°C; use reactant A as the positive electr...

Embodiment 2

[0052] The preparation method of high graphene oxide is mainly characterized in that it is different from step (2) in embodiment 1, step (2) in this embodiment does not add ammoniacal liquor to adjust the pH of the solution, and the specific method comprises the following steps:

[0053] (1) Preparation of reactants: graphite foil is pressed into graphite flakes, and the thickness of the pressed sheet is 3mm, as the positive electrode reactant A during electrolysis; the platinum electrode is selected as the negative electrode of electrolysis; ammonium sulfate is selected to be made into 1mol / L Ammonium sulfate solution B;

[0054] (2) Reaction stripping: place the electrolyte device in a constant temperature environment at 0°C; use reactant A as the positive electrode, platinum electrode as the negative electrode, and solution B as the electrolyte, and maintain it stably for 2 hours under a DC voltage of 3V; then increase the voltage and Keep it stable at 10V, and continue to ...

Embodiment 3

[0058] A kind of preparation method of high intrinsic degree graphene is characterized in that, the method comprises the following steps:

[0059] (1) Preparation of reactants: Scale graphite is pressed into graphite flakes, and the thickness of the pressed sheets is 4mm, as the positive electrode reactant A during electrolysis; the platinum electrode is selected as the negative electrode of electrolysis; ammonium bisulfate is selected as the electrolyte, and it is made into 0.6mol / L ammonium bisulfate solution B; according to the volume ratio of 3% in the B solution, that is, every 100mL of the B solution is added with 3mL of 30% mass fraction of ammonia water, the pH value of the B solution is adjusted to be 10, and the mixed solution is uniformly Stir for 15 minutes, and sonicate for 5 minutes at room temperature (25°C) at a power of 40W to obtain alkaline electrolyte solution C;

[0060] (2) Reaction stripping: place the electrolyte device in a constant temperature environ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com