A preparation method of an ultra-thin copper foil with a carrier that is easy to peel and has a clean interface

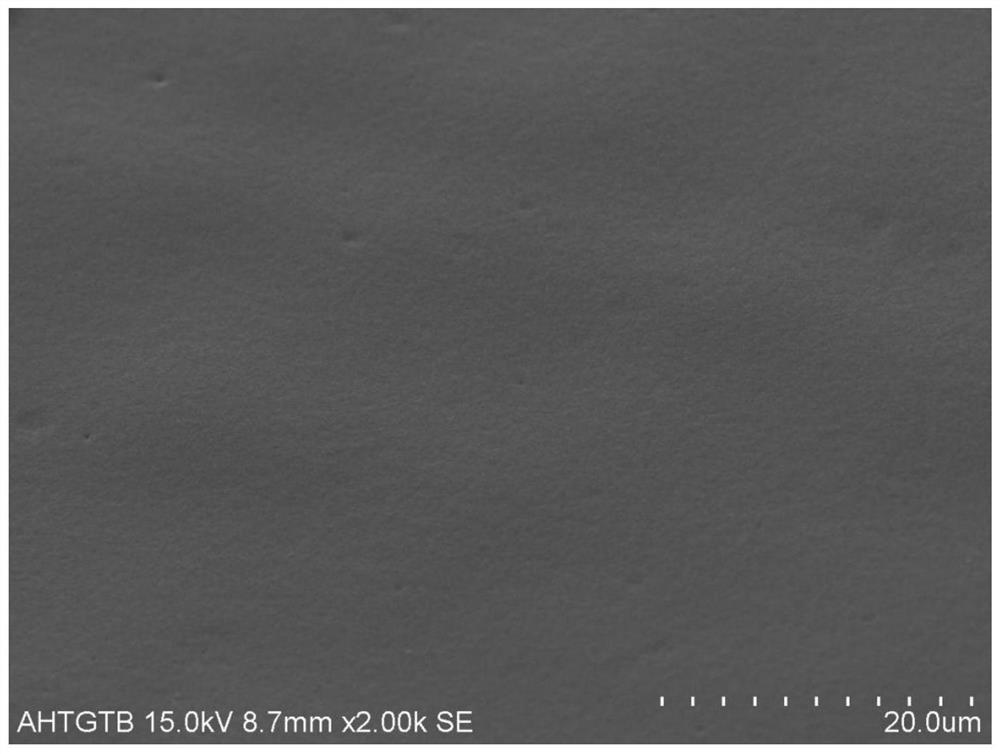

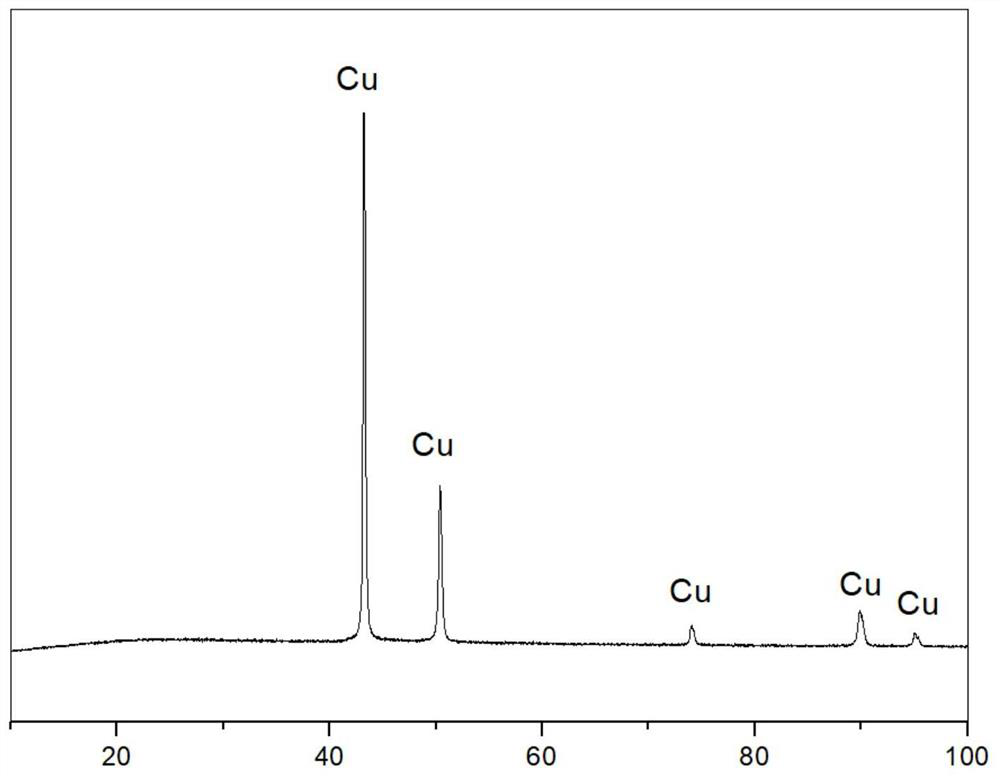

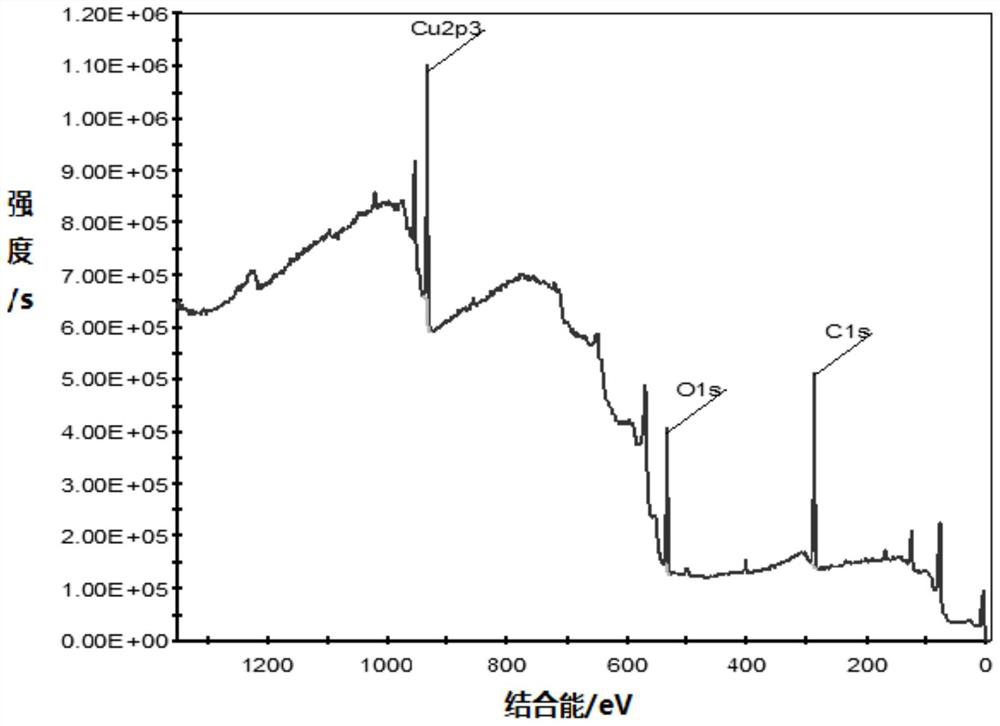

A technology of carrier copper foil and copper foil, which is applied in the field of preparation of ultra-thin copper foil with carrier, can solve the problems of carrier copper foil tearing, high peeling strength of the peeling layer, and adhesion of ultra-thin copper foil, so as to improve the surface smoothness High degree, stable peeling performance, clean interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] According to one preferred embodiment of the present invention, the organic layer contains the organic substance having a cyclic structure, preferably selected from a five-membered ring and / or organics six-membered ring, more preferably selected from melamine, benzotriazole, benzimidazole, 6-chloro-1-hydroxybenzene and at least one triazole and 1H-1,2,3- triazole in.

[0042] According to the present invention, preferably, the alloy layer obtained by a plating solution containing a complexing agent and an alloy of at least one soluble sulfate.

[0043] In some embodiments of the present invention, preferably, based on the total content of the liquid alloy, the alloy is solution soluble sulfate 10-200g / L, preferably 30-80g / L; complexing agent content of 50-300g / L, preferably 150-200g / L. Using the preferred conditions more conducive to obtaining a uniform alloy layer deposited on the surface, help to reduce the roughness of the ultra-thin copper foil surface.

[004...

Embodiment 1

[0100] (1) Preparation carrier copper foil

[0101] Acid washing treatment: The concentration of concentration to 10 vol.% Dilute sulfuric acid, pumped into the acid wash tank, and the copper foil having a thickness of 18 μm was placed in the pickled tank, soaked, the copper foil was subjected to the copper foil after soaking. Cleaning, the transmission speed of the conveying roller is 20 m / min, and the fluid cycle rate in each tank is 15 L / min;

[0102] Electroplating treatment: The copper foil after cleaning enters the electroplating groove in which the alloy liquid is applied, wherein the nickel sulfate concentration in the alloy liquid is 15 g / L, the zinc sulfate concentration is 60 g / L, and the potassium pyrophosphate is 180 g / L. The conditions of the plating treatment include: temperature of 30 ° C, current density is 3A / DM 2 Time is 5 s;

[0103] Coating treatment: After the copper foil after the plating treatment, the copper foil was washed away from the ionize...

Embodiment 2

[0115] (1) Preparation carrier copper foil

[0116] Acid washing treatment: The concentration of concentration to 10 vol.% Dilute sulfuric acid, pumped into the acid wash tank, and the copper foil having a thickness of 18 μm was placed in the pickled tank, soaked, the copper foil was subjected to the copper foil after soaking. Cleaning, the transmission speed of the conveying roller is 15 m / min, and the fluid cycle rate in each of the troughs is 20 L / min;

[0117] Electroplating treatment: The copper foil after cleaning enters the electroplating groove in which the alloy liquid is applied is plated, wherein the cobalt sulfate concentration in the alloy liquid is 20 g / L, the zinc sulfate concentration is 30 g / L, sodium citrate concentration is 60 g / L. The conditions of the plating treatment include: a temperature of 35 ° C, current density is 4A / DM 2 Time is 4s;

[0118] Coating treatment: After the copper foil after the plating treatment, the copper foil was washed awa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com